Do you know what types of vitamin gummies are available now?

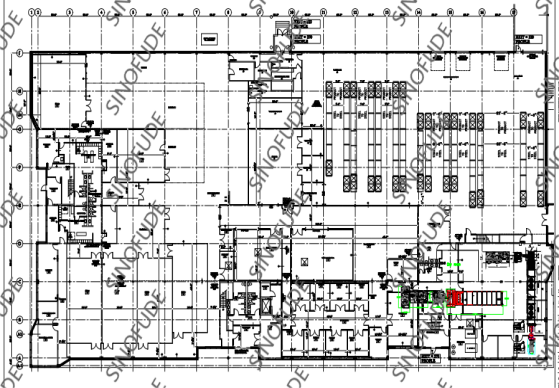

In 2014, SINOFUDE partnered with one of the largest healthcare product companies in the United States. Through preliminary communication with the US client, the client mentioned that due to business expansion, their head office plans to carry out a health product vitamin gummy project to achieve product diversification. The customer said that although they are not very clear about the production process of vitamin gummy, they have been inspecting this project for a long time and have visited many factories, but have not received satisfactory results. After visiting SINOFUDE company, they found that

SINOFUDE Company has rich experience in pharmaceutical and food machinery, and the targeted solutions proposed are very specific and visual.

That's why they decided to cooperate with SINIFUDE company. They have their own formula research and development, and want SINOFUDE company to build a large production line according to their formula process, factory layout, and technical requirements, with an hourly output of two tons.

Based on over 20 years of project experience, SINOFUDE mentioned that the project needs to fully consider the customer's factory layout and the nature of the customer's product formula.

And considering that this is the first time the client has collaborated with us, they may be concerned about whether our design philosophy aligns with their ideas.

In order to reduce customers' worries, the SINOFUDE team integrated their ideas and concerns, using three-dimensional diagrams and past cases to explain and convey the entire design concept to customers in multiple dimensions.

After discussion at the meeting, the customer was very satisfied with the design results of SINOFUDE.

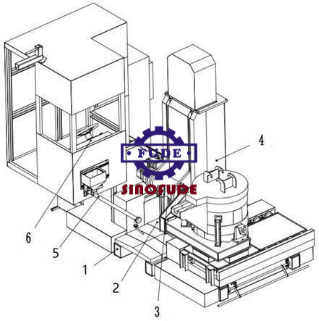

After seeing the first set of designs, they felt that SINOFUDE company could understand their needs and recognize our professionalism. After a week of in-depth exploration and optimization, SINOFUDE has finally designed a highly convenient and automated perfect machine design for customers.

When manufacturing machines, SINOFUDE's technical personnel rely on exquisite craftsmanship and control over details to ensure strict control over each machine and small details, making the products automated, high-precision, aesthetically pleasing, durable, and easy to clean and maintain.

After production was completed, SINOFUDE company considered that the customer was not proficient in installation, so they arranged professional assembly technicians to provide on-site installation for the customer, so that they could proceed smoothly during the installation process.

During this process, SINOFUDE company successfully created a new highly automated vitamin gummy production line for American customers, providing them with push plate vitamin gummy pouring production line, ultrasonic demolding device, tubular boiling pot, fully enclosed production line, etc.

Through customer feedback, we can see that the entire factory is very clean and tidy, with a high degree of automation and almost no need for manual labor.

Now, this American customer has been using this production line for nearly a decade, and the customer stated that the machine is well designed and durable, with almost no maintenance required. This not only helped them occupy a significant portion of the American vitamin gummy market, but also expanded their brand influence. Even if there is a high demand from customers during the peak season, they are not in a hurry because SINOFUDE company provides a large production line for vitamin gummies and a high degree of automation, providing them with a very comfortable experience.

SINOFUDE Company appreciates the trust and support of our customers. We always adhere to our wholehearted service philosophy, providing the best guidance and advice to every customer who comes to SINOFDUE company with the most professional service attitude and the highest quality and efficient work efficiency.

At the same time, SINOFUDE company also takes you to learn about the following common candy machinery:

2. SINOFUDE high-precision CFA batch mixing system

-Accurately quantify the various added elements required for each batch of syrup, even small component operations can be accurately completed

-Compared to online mixing, batch mixing can more accurately control the addition of element weight without being affected by other factors.

3. Compared to chain pushing, the push plate depositing machine can better meet your pharmaceutical needs.

3. The machines manufactured by SINOFUDE company can pass various international certifications such as CE, FDA, UL, ISO, GMP, etc.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.