With strong R&D strength and production capabilities, SINOFUDE now has become a professional manufacturer and reliable supplier in the industry. All our products including candy depositing line are manufactured based on the strict quality management system and international standards. candy depositing line SINOFUDE is a comprehensive manufacturer and supplier of high-quality products and one-stop service. We will, as always, actively provide prompt services such. For more details about our candy depositing line and other products, just let us know. produces candy depositing line in strict accordance with national and industry standards, and establishes a strict quality control system to strictly control product quality to ensure that the produced candy depositing line are qualified products with both good performance and excellent quality.

A gummy candy production line designed specifically for gummy candy manufacturers. With this gummy machine, you can produce up to 600 kg of gummy candies per hour at high speed, efficiency and reliability. It is easy to operate and requires very little maintenance, so if you are looking for an automated, high-quality gummy candy production line, the CLM600 is a good choice. You can produce gummy candies of various shapes and sizes with this gummy making machine.

Features of gummy machine:

1. Using PLC, the performance is more stable, and programming automatically controls the vacuum sugar boiling temperature, time, insulation temperature and pouring speed.This gummy bear machine has advanced technology, which can increase production efficiency and reduce costs.

2. The large touch screen displays the process flow chart, working status of each part, setting and display of parameters such as temperature and pouring speed, making it easier for users to operate and master;The whole gummy bear equipment is designed with a reasonable structure and is easy to operate and maintain. The operation panel is located on the left side of the gummy bear machine to facilitate one-person operation.

3. The production capacity of series products can range from 150kg to 600kg per hour;

4. All parts of the gummy manufacturing machine are made of stainless steel 304, which is safe to use for food processing. The production process is controlled by PLC, which ensures that all products are of high quality.Frequency conversion speed regulation controls the accurate flow of sugar liquid, and the quality of sugar paste is stable;

5. Conveyor chain belt, cooling system, and double demoulding mechanism ensure demoulding;

6. The dynamic mixer completes the quantitative addition and mixing of flavors, pigments, and acids online;

7. The optional chocolate quantitative filling system can produce chocolate-filled candies;

8. Candies of various shapes can be produced according to different molds;

9. By replacing some of the cooking equipment and molds, the candy production line can produce soft candies, hard candies, spherical lollipops, flat lollipops, etc.

Model | CLM600-A |

Capacity | 600 |

Depositing stroke (Pcs) | 80 |

Pcs of molds | 520 Long type |

Chilling Capacity | 20HP |

Electric power needed | 45-80kw |

Compressed air consumption | 1.20m3/min |

Gross weight (Kgs) | Approx.12000 |

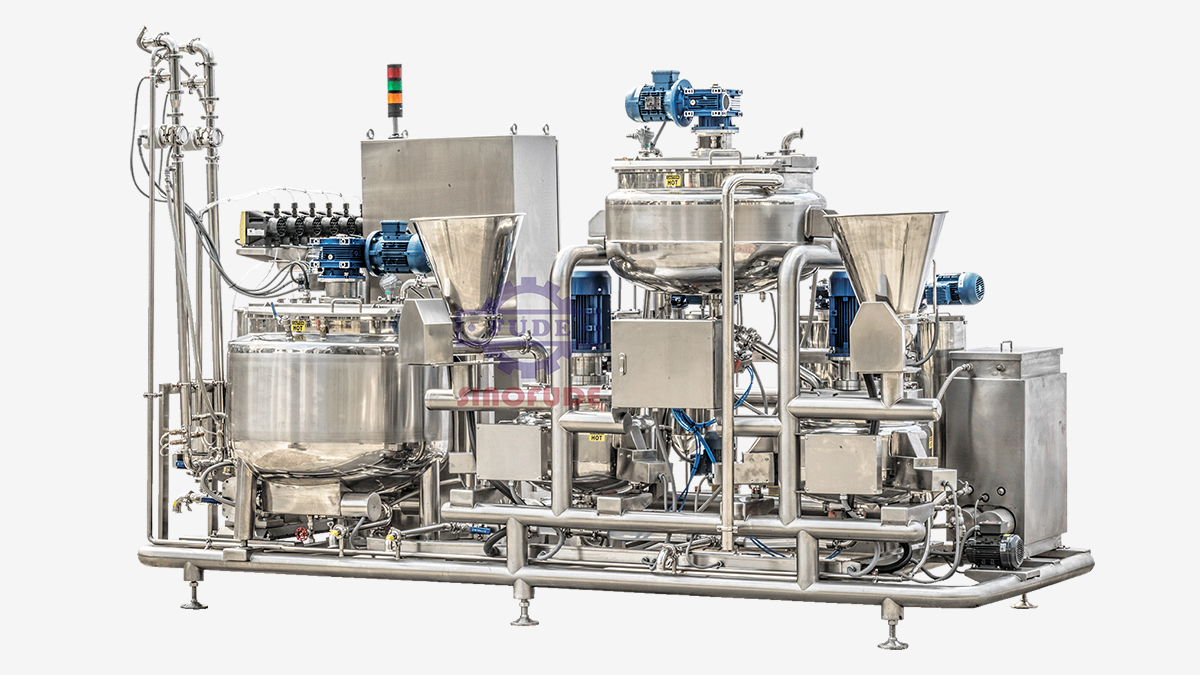

CLM600 is a highly automatic and high capacity gummy candy production line that SINOFUDE is proud of

Weighing and cooking system

This part is used for weighing the main raw materials, such as sugar, glucose syrup and gelatin pectin and other gel. Contains elevator, weighing tank, mixing tank, storage tank. (For reference only, the specific configuration needs to be determined according to the specific recipe and process)

CFA Mixing system

This part is used for mixing and adding flavors, colors, acid and some functional substances, which can precisely control the amount of additives and make the syrup fully mixed without being affected by any external factors.

CLM600 Depositing Machine

Sinofude self-developed high-quality, high-yield, highly-automated gummy candy production line. The whole gummy proction line is designed according to pharmaceutical machinery standards, SUS304+SUS316 stainless steel, in line with pharmaceutical and food safety. Precise depositing, easy to clean, no hygienic dead ends. It is an excellent equipment for high-capacity production of ordinary gummy candy and health-care gummy candy.

Depositing Machine

Advance type machine equipped with 2 layer cooling, the air recycling system and mold conveyor system separated by a stainless steel clapboard, which prevent the dust drop to the candy surface.Cold air will convey to the candy convey system by the 2 end of the cooling tunnel.The 2 guide rail of the back side of the cooling tunnel equipped with automatic tension device, which protect the chain and prolong the service life. Demold device with tank chain demolding and brush .PU conveyor with diamond pattern, which prevent the candy stick on the conveyor, it’s easy to clean and with longer service life.

Shanghai Fude Machinery Manufacturing Co., Ltd. automatic soft candy production line integrates mechanical, electrical and pneumatic control, with a reasonable and compact structure and a high degree of automation. It has high production efficiency and can produce hard candies, lollipops, sandwich candies, gelatin soft candies, pectin soft candies, and carrageenan soft candies. Single-color, double-flavor and double-color spray flowers, double-flavor and double-color double-layer, three-flavor and three-color spray flowers, as well as crystal candies, sandwich candies, striped candies, and Sioke, etc. The candies produced by Sinofude's automatic soft candy pouring production line have the characteristics of crystal smoothness, clear spray stripes, stable filling amount and position, and good taste, and are very popular among domestic and foreign customers.

Regarding the attributes and functionality of the candy depositing line, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. candy depositing line QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In essence, a long-standing candy depositing line organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Shanghai Fude Machinery Manufacturing Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Yes, if asked, we will supply relevant technical details regarding SINOFUDE. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In China, ordinary working time is 40 hours for employees who work full time. In Shanghai Fude Machinery Manufacturing Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Boba Machines and an unforgettable experience of partnering with us.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.