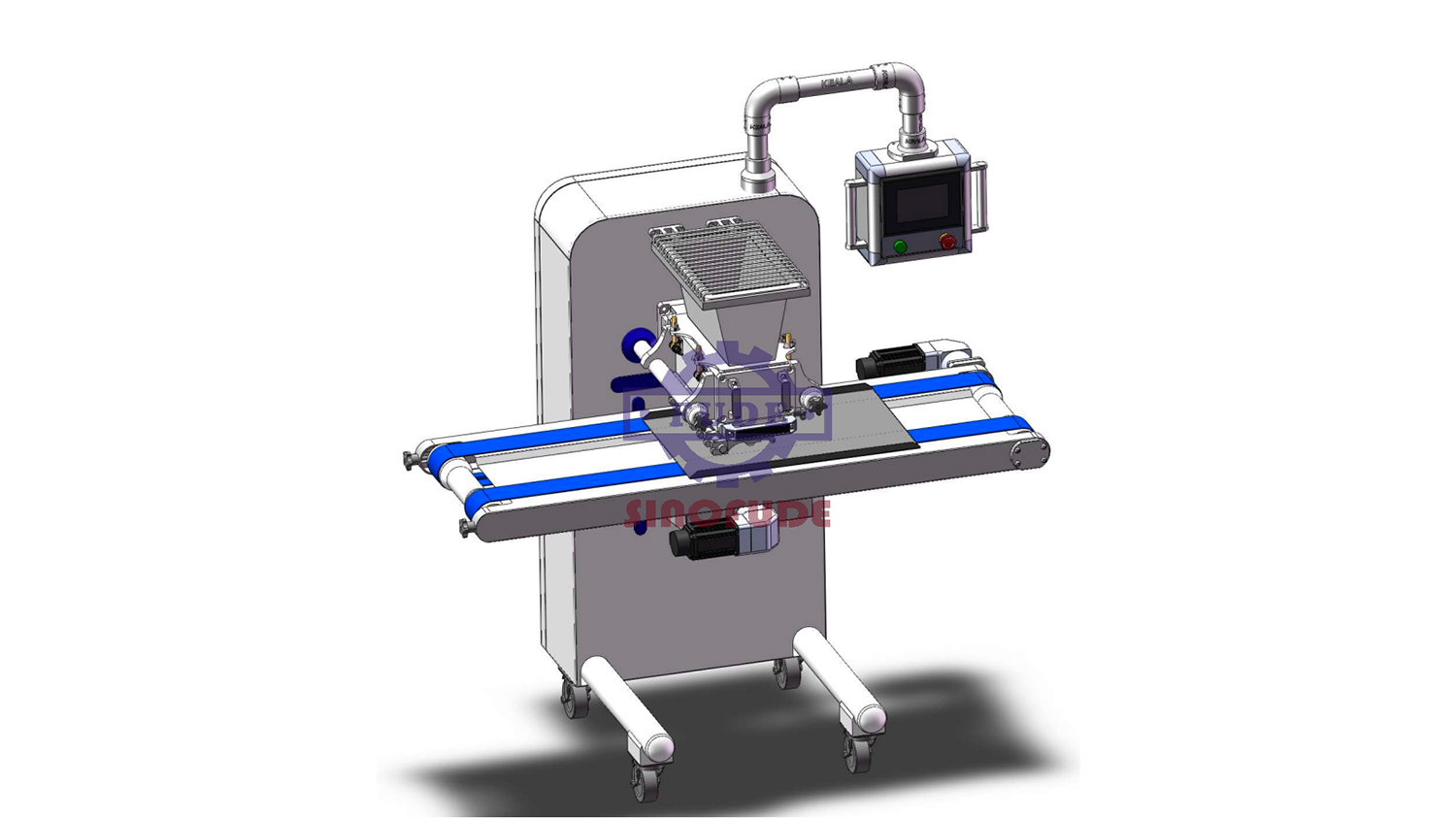

Cookie machine model:CK-400A

About cookie machine of output: 600kg/h

Model | CK400 | CK600 | CK800 | CK1000 |

Capacity (kg/h) | 600 | 900 | 1200 | 1500 |

Pan size(mm) | 400*600 | 600*800 | 800*600 | 1000*600 |

Total power(KW) | 4.9 | 5.4 | 6.6 | 7.8 |

Electrical source | Determined according to customer requirements (generally) 380V/50Hz) | |||

overall size(mm) | 1500*875*1680 | 1500*1100*1680 | 1500*1100*168080 | 1500*1100*1680 |

Weight(kg) | 600 | 900 | 1250 | 1550 |

Adavantage of soft CK-400A biscuit machine

CK-400A biscuit machine is the most efficient cookie machine with big capacity, and it contributes to a successful manually operated cookie production line.This powerful soft biscuit equipment is able to produce all types of cookies. With hygienic design built right in, space saving merit, CK-400A cookie equipment is ideal for production to validation standards for cookie products.

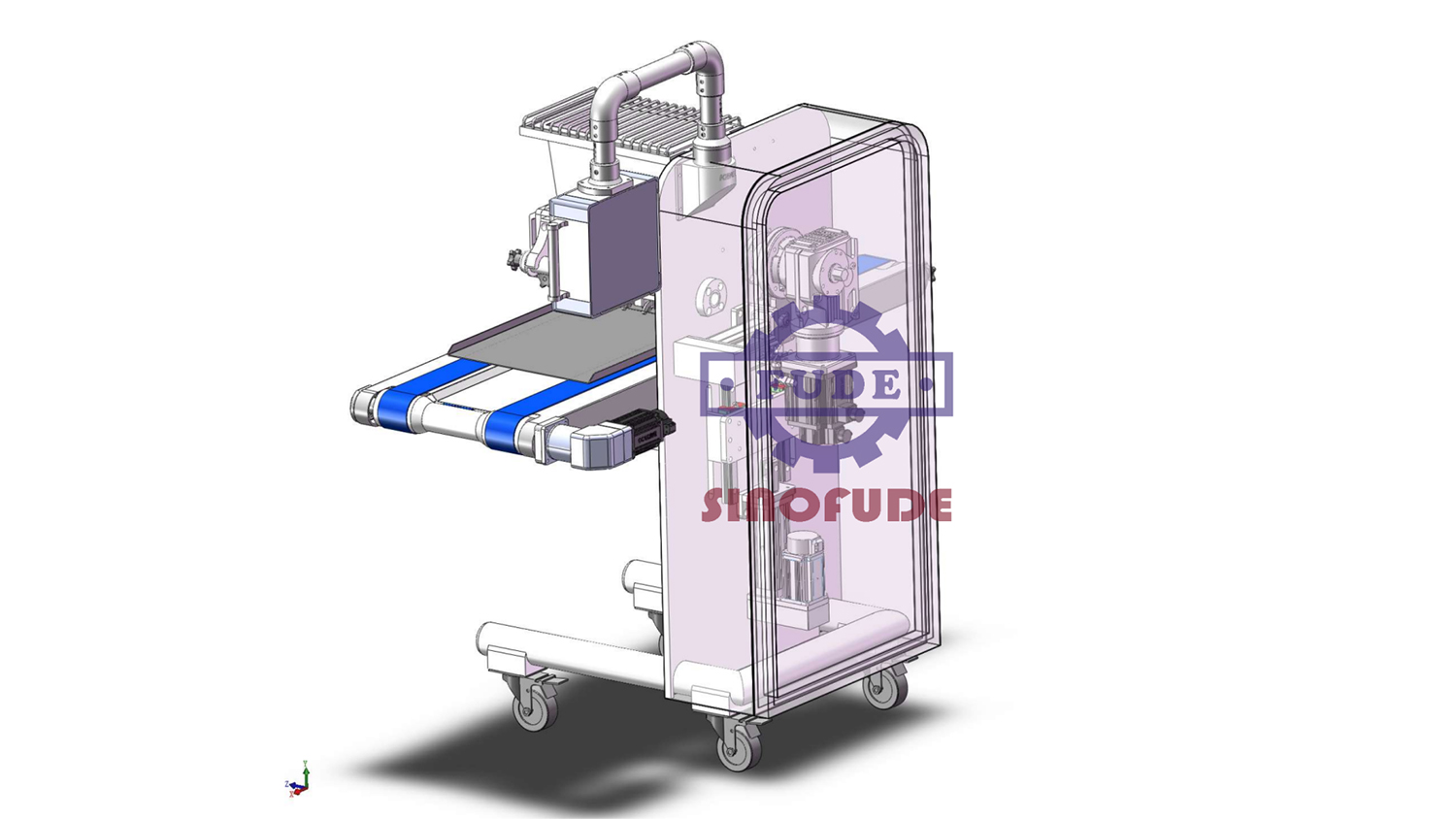

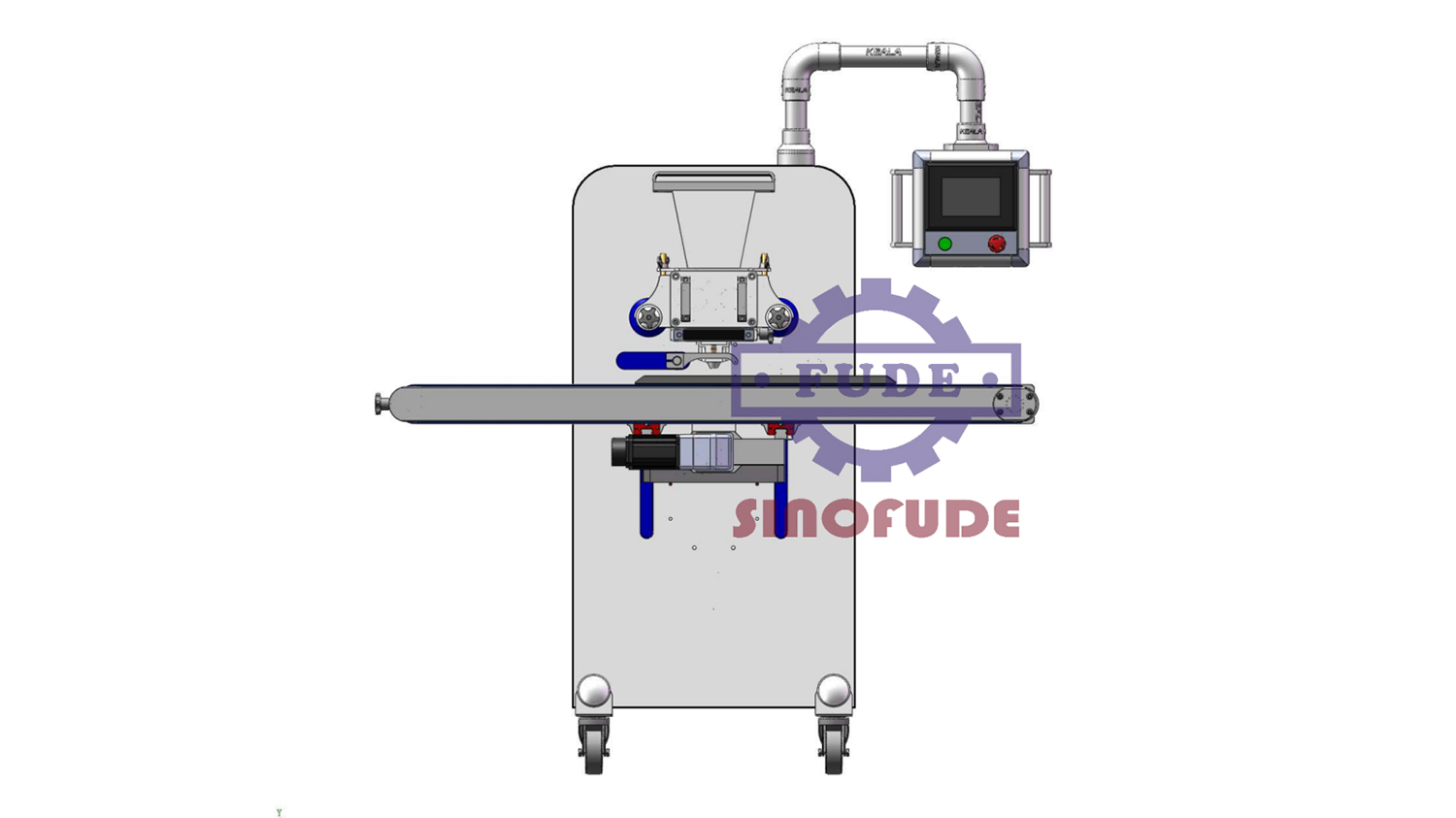

The cookie machine produced by the cookie machine is composed of a stainless steel frame, a servo motor power system, a tray canvas transmission system, a tray up and down lifting system, a feeding roller cookies mechanism, and a wire cutting system. All power parts of the cookie machine are servo motors, equipped with high-quality reducers, photoelectric control systems with high agility performance, and human-machine interface touch-screen operating systems. The production speed and product shape can be set according to actual needs. Put the prepared fabric into the hopper, feed through the feeding roller and rotate and extrude the forming die to become the cookie blank. The tray is placed on the conveyor belt with lifting function. The cookie machine conveyor belt can realize the movement of various technical parameters, use and operation. , maintenance is very convenient.

Features

The performance characteristics of the universal cookie machine:

1. Strong flexibility. Just a simple operation of the same pastry machine can produce various kinds of cakes. This function is very effective for the market demand of small batch and multi-variety.

2. High precision, high speed and. The equipment can not only work at high speed and stably, but also minimize the time of abnormal production (such as waiting for raw materials, mechanical maintenance, finding and troubleshooting, etc.), which is a direct means to increase the rate.

3. Safety, energy saving and environmental protection. This includes protecting the personal safety of equipment operators and product consumers to the greatest extent possible, reducing energy consumption (such as electricity, water, and gas) as much as possible, and adopting appropriate processes to minimize the adverse impact of the production process on the environment.

4. Strong interconnectivity. It is necessary to realize the communication between single machines conveniently and quickly, so that the single machines can be connected into a whole line, and the communication between the single machine or the whole line and the upper-level monitoring system (such as SCADA, MES, ERP, etc.) can be realized conveniently and quickly.

Product pictures

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.