Ma gummies amabwera mosiyanasiyana komanso amawonekedwe amakona anayi komanso osakhazikika. M'zaka zaposachedwapa, zimbalangondo, maswiti a gummy, ndi zina zotero zakhala zotchuka kwambiri.

Akatswiri amakampani akuti ma gummies opanga ma model sizochitika zaposachedwa koma akhala otchuka nthawi zonse. Chinsinsi cha chifukwa chake ogula nthawi zonse amakhala okonzeka kulipira iwo ali mu makhalidwe a gummies opangidwa okha. Amakhala ndi mawonekedwe enaake komanso kukopa kwina. Makhalidwewa amawapangitsa kukhala osiyana ndi zinthu zina zowoneka bwino. Mwachitsanzo, anthu padziko lonse lapansi zaka zambiri zapitazo ankakonda zimbalangondo ndi masiwiti otafuna, ndipo akadali ndi msika winawake wogula zinthu.

Kupitilira apo, ma gummies ogwira ntchito amaphwanya zotchinga pakati pa chakudya chanthawi zonse ndi zowonjezera. Imawonjezera zinthu zina zogwirira ntchito kuti chowonjezeracho chikhale cholunjika komanso chogwira ntchito.

Ma gummies ogwira ntchito ali ndi izi:

Maonekedwe abwino: Ma gummies ogwira ntchito omwe amagulitsidwa pamsika nthawi zambiri amabwera m'matumba owala komanso okongola okhala ndi mawonekedwe osiyanasiyana, omwe amakwaniritsa zosowa za achinyamata.

Zosavuta kudya: Fomu ya gummy ndi yosavuta kunyamula ndipo imatha kusangalala nthawi iliyonse komanso kulikonse.

Zochitika zambiri zogwiritsira ntchito: Ma gummies ogwira ntchito sangagwiritsidwe ntchito ngati mankhwala achipatala, komanso monga zokhwasula-khwasula, kukwaniritsa zosowa za achinyamata kuti akhale ndi moyo wathanzi.

Ma gummies ogwira ntchito amaphwanya zotchinga pakati pa chakudya wamba ndi zinthu zachipatala - ali ndi zosakaniza zogwira ntchito kuposa chakudya wamba, zomwe zimapangitsa kuti zakudya zowonjezera zikhale zolunjika komanso zogwira mtima, koma alibe mawonekedwe ozizira azinthu zamankhwala, zomwe zimapangitsa achinyamata kukhala ndi moyo wathanzi. pakudya zokhwasula-khwasula.

Mzere wopanga maswiti a gummy ndi chida chomwe chimapanga mosalekeza mitundu yofewa ya colloidal. Itha kutulutsa mawonekedwe osiyanasiyana, mtundu umodzi, mitundu iwiri kapena masangweji a gummy candies posintha nkhungu kapena kuthira mutu. Mzere wonse wopangira umakhala ndi poto yowira, poto yozizirira, poto yosungiramo, makina otsanulira, lamba wozizirira, mchenga wamtundu wa drum ndi makina opaka mafuta (posankha), ndi makina opukutira (posankha). Itha kugwiritsidwa ntchito popanga mitundu yosiyanasiyana ya gel osakaniza, monga gelatin, pectin, carrageenan ndi chingamu arabic. Kupanga zokha sikungopulumutsa antchito ndi malo, komanso kumachepetsa ndalama zopangira. Muthanso kuwonjezera zida zina zopangira maswiti olimba, ma lollipop, ma tofi, ndi zina.

Onani kuthekera kosatha ndi makina a maswiti a SINOFUDE. Zida zathu zopangira maswiti a gummy zitha kusinthidwa malinga ndi zomwe makasitomala athu amafuna. Timanyadiranso kukumana ndi ukhondo wapamwamba komanso miyezo yapamwamba komanso kupereka mapangidwe apamwamba osalowa madzi. Phunzirani zamakina athu apamwamba kwambiri, amalonda a fudge ndikupeza makina omwe akuyenera kupanga zomwe mukufuna.

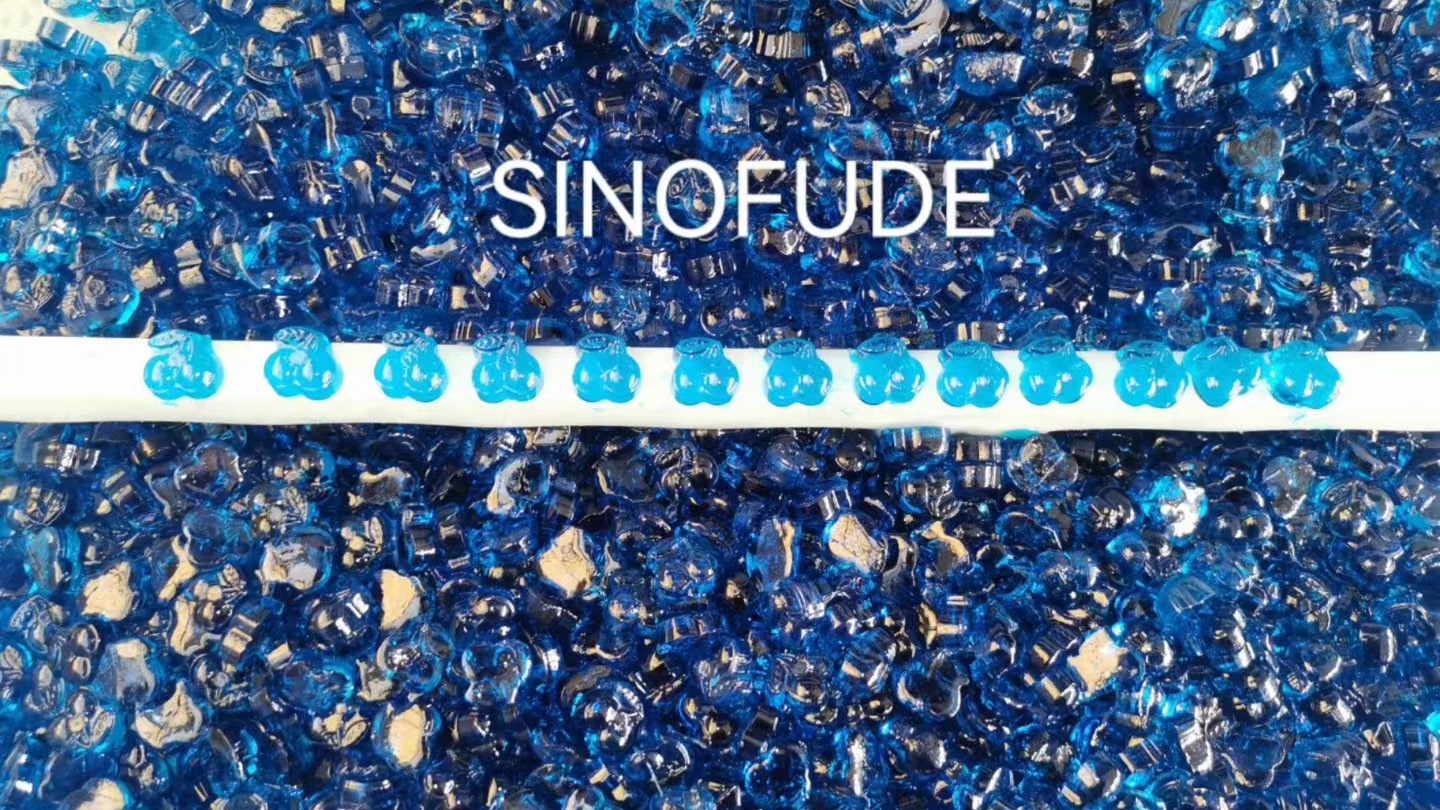

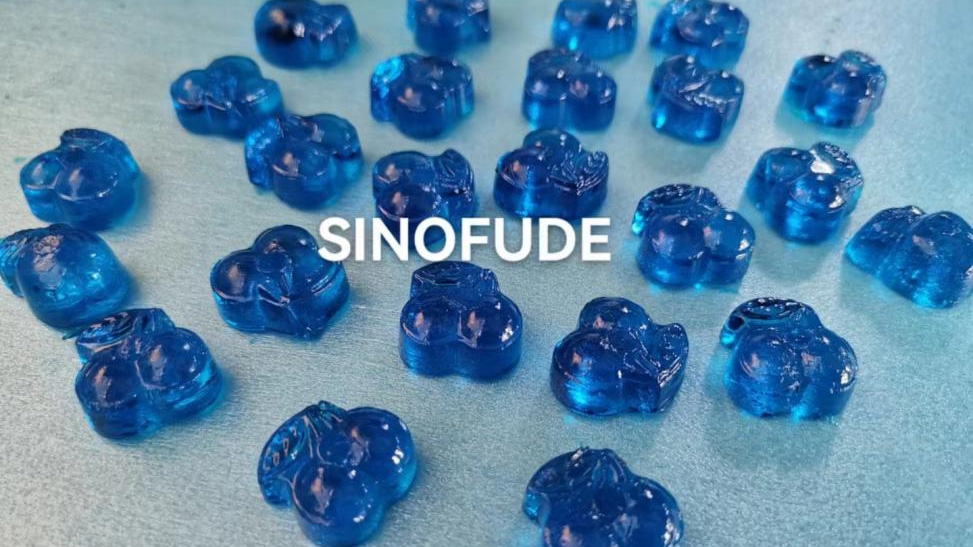

SINOFUDE gummy kupanga maswiti:

1. Kufalikira kwapadziko lonse: Odalirika m'maiko opitilira 100, omwe ali ndi chikoka champhamvu ku United States ndi Europe.

2. Zamakono zamakono: Mapangidwe athu oyambirira a "plug and play" amaonetsetsa kuti zopanga zopanda pake zimagwira ntchito bwino.

3. Beyond Food Grade: Makina athu a fudge amalonda amaika muyeso ndikuposa mtundu wa makina onse a chakudya.

4. Zatsopano: Ndalama zathu mu R&D imayendetsa zotsogola zomwe zimakupatsani mphamvu kuti mutsogolere bizinesi yanu.

Mawonekedwe a SINOFUDE gummy candy depositing zida:

1. Mphamvu yopangira zinthu zingapo imatha kuyambira 150kg mpaka 600kg pa ola limodzi;

2. Gelatin yoyendetsedwa bwino ndi PLC (pectin, gelatin) yopangira ndi kupanga kupanga imagwirizanitsa makina, magetsi ndi pneumatic control. Ili ndi mawonekedwe omveka komanso ophatikizika komanso digiri yapamwamba yamagetsi. Imakhala ndi magwiridwe antchito apamwamba ndipo imatha kupanga zidutswa zing'onozing'ono molingana ndi masanjidwe osiyanasiyana. Mtundu, kununkhira kwapawiri, mitundu iwiri, wosanjikiza kawiri ndi ma gummies ena a gelatin. Pogwiritsa ntchito Siemens PLC, ntchitoyo imakhala yokhazikika, ndipo mapulogalamu amawongolera kutentha kwa shuga wa vacuum, nthawi, kutentha ndi kutsanulira; chachikulu chokhudza kukhudza chinsalu chimasonyeza ndondomeko otaya tchati, udindo ntchito gawo lililonse, kukhazikitsa ndi kusonyeza magawo monga kutentha ndi kuthira liwiro, etc., kulola owerenga Kusavuta ntchito ndi bwino;

3 Makinawa amagwiritsidwa ntchito popanga mosalekeza mitundu yosiyanasiyana ya maswiti ofewa a colloidal (maswiti ofewa a gelatin). Ndi chida chabwino chopangira maswiti a colloidal. Kapangidwe kaukhondo, kudzaza kochulukira ndi kusakanikirana kwa zokometsera, ma pigment, ndi ma acid zitha kumalizidwa pa intaneti. Kupanga zokha kumatha kukhala kokhazikika, kupulumutsa antchito ndikukhala ndi malo, potero kumachepetsa ndalama zopangira.

4. Mzere wonse wopangira umapangidwa molingana ndi miyezo ya GMP, ndi njira yopangira mapaipi, zinthu zochepa zaumunthu, khalidwe lachinthu lokhazikika, ndipo limakwaniritsa zofunikira zaukhondo za GMP.

5. Dongosolo losakaniza la kukoma ndi mtundu limagwiritsa ntchito mpope wochulukira, kusakaniza kosasunthika ndi kusakaniza kwamphamvu kuti zitsimikizire mtundu wa yunifolomu wa madzi osakaniza. Kuchuluka kwa pigments ndi zokometsera zingathe kusinthidwa mwakufuna. Malizitsani kuwonjezera ndi kusakaniza zokometsera, inki, ndi ma asidi pa intaneti;

6. Mutu wothira wakonzedwa bwino, kuchuluka kwa kuthirira ndi kolondola, kusinthidwa ndi kugwiritsira ntchito nkhonya ndizosavuta komanso zosavuta, ndipo zimasinthidwa payekha. Kugunda kwa nkhonya (kulemera kwa ma granules a shuga) kungasinthidwe pa intaneti.

7. Chophimba chotsekemera chimakhala ndi magetsi otenthetsera magetsi, ndipo chowongolera kutentha kwa PID trapezoidal ndi cholondola ndipo chikhoza kukhazikitsidwa.

8. Njira yozizirirayo yawongoleredwa. Makina onse a firiji amasonkhanitsidwa mufiriji ndi kutalika kogwirizana. Kutalika kwa ngalandeyo kumatalikitsidwa ndipo mawonekedwe ake ndi okongola. Kuzizira kozizira kumakhala bwino kusiyana ndi zomwe zikuwonetsedwa mu chithunzichi ndipo kuwongolera kutentha kumakhala kolondola. Mufiriji uyu ali ndi chipangizo choziziritsira madzi.

9. Njira yowonongera imatengera kapangidwe kake katsopano ka kampani yathu ndipo imakhala ndi maburashi ozungulira ndi zowuzira mpweya. Zomangamanga zitatuzi zimakwaniritsa 100%.

10 Lamba woziziritsa wamakina wothira maswiti wofewawa amagwiritsa ntchito lamba wa PU, womwe umakhala ndi moyo wautali wautumiki, mawonekedwe okongola, ndipo ndiosavuta kuyeretsa ndi kukonza. Pansi pa lamba wa mauna amatengera njira ya njanji yowongolera, kuti lamba wonyamulirayo asapunduke. Makina osakhazikika amatha kusinthidwa malinga ndi zomwe makasitomala akufuna.

11 Perekani mitundu yosiyanasiyana ya nkhungu zopangira maswiti a 2D3D amitundu yosiyanasiyana.

12. Sinthani gawo lophika, chipangizo ndi nkhungu. Mzerewu umatha kupanga masiwiti olimba, ozungulira komanso osalala amitundu itatu.

Ngati muli ndi chidwi ndi zida za maswiti a gummy, chonde omasuka kulumikizana nane.

Webusayiti: https://sinofudegroup.com/

Lumikizanani Nafe

Ingosiyani imelo kapena nambala yanu yafoni pa fomu yolumikizirana kuti tikupatseni ntchito zambiri! funsani fomu kuti tikupatseni ntchito zambiri!

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Ufulu Onse Ndiotetezedwa.