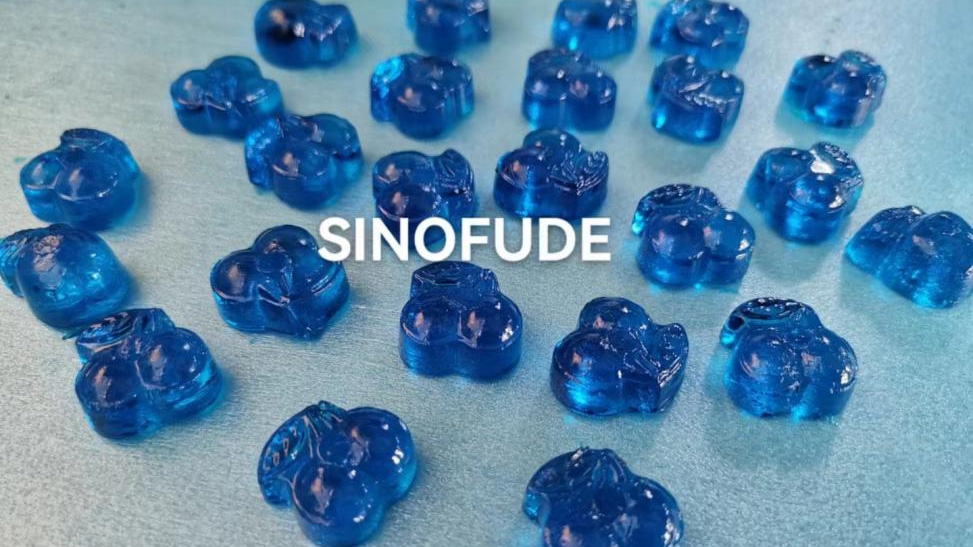

Gummies come in a variety of flavors and in rectangular and irregular shapes. In recent years, gummy bears, eyeball gummy candies, etc. have been quite popular.

Industry experts say modeling gummies are not just a recent phenomenon but have always been popular. The key to why consumers are always willing to pay for them lies in the characteristics of the shaped gummies themselves. They have a certain visual impact and a certain degree of appeal. These characteristics make them different from other ordinary shaped products. For example, gummy bears and chewy hamburger candies were loved by people all over the world many years ago, and they still have a certain consumer market.

Beyond that, functional gummies break down barriers between regular food and supplements. It adds some functional ingredients to make the supplement more targeted and efficient.

Functional gummies have the following characteristics:

Good appearance: Functional gummies sold on the market usually come in bright and cute packaging with various shapes, which meet the aesthetic needs of young people.

Convenient to eat: The gummy form is easy to carry and can be enjoyed anytime and anywhere.

Rich application scenarios: Functional gummies can not only be used as health care products, but also as snacks, meeting the needs of young people for healthy lifestyles.

Functional gummies break the barriers between ordinary food and health care products - they have more functional ingredients than ordinary food, making dietary supplements more targeted and efficient, but they do not have the cold attributes of health care products, making young people satisfy their healthy lifestyle by eating snacks.

The gummy candy production line is a piece of equipment that continuously produces different types of colloidal soft candies. It can produce various shapes, single color, double color or sandwich gummy candies by changing the mold or pouring head. The entire production line consists of a boiling pot, a cooling pot, a storage pot, a pouring machine, a cooling conveyor belt, a drum-type sand and oil coating machine (optional), and a polishing machine (optional). It can be applied to the production of various gel raw materials, such as gelatin, pectin, carrageenan and gum arabic. Automatic production not only saves manpower and space, but also reduces production costs. You can also add some equipment to make hard candies, lollipops, toffees, etc.

Explore the endless possibilities with SINOFUDE gummy candy machine. Our gummy candy production line equipment can be customized according to the specific requirements of our customers. We are also proud to meet high hygiene and quality standards and offer state-of-the-art waterproof designs. Learn about our high-quality, commercial fudge machines and find the machine that best suits your production needs.

SINOFUDE gummy candy production line:

1. Global coverage: Trusted in more than 100 countries, with strong influence in the United States and Europe.

2. Cutting-edge technology: Our original “plug and play” design ensures unparalleled production efficiency.

3. Beyond Food Grade: Our commercial fudge machines set the standard and exceed the quality of general food machinery.

4. Innovation: Our investments in R&D drive breakthrough advancements that empower you to lead your industry.

Features of SINOFUDE gummy candy depositing equipment:

1. The production capacity of series products can range from 150kg to 600kg per hour;

2. The fully automatic PLC-controlled gelatin (pectin, gelatin) casting and molding production line integrates mechanical, electrical and pneumatic control. It has a reasonable and compact structure and a high degree of automation. It has high production efficiency and can produce single pieces according to different selection configurations. Color, double flavor, double color, double layer and other gelatin gummies. Using Siemens PLC, the performance is more stable, and programming automatically controls the vacuum sugar boiling temperature, time, holding temperature and pouring speed; the large touch screen displays the process flow chart, the working status of each part, the setting and display of parameters such as temperature and pouring speed, etc., allowing users to Easier to operate and master;

3 This machine is used for the continuous production of various shapes of colloidal soft candies (gelatin soft candies). It is an ideal equipment for producing colloidal candy. Hygienic structure design, quantitative filling and mixing of flavors, pigments, and acids can be completed online. Automated production can produce stable quality, save manpower and occupy space, thereby reducing production costs.

4. The entire production line is manufactured according to GMP standards, with a pipelined production process, few human factors, stable product quality, and meets food GMP hygiene requirements.

5. The flavor and color mixing system adopts a quantitative pump, static mixing and dynamic mixer to ensure uniform color of the mixed syrup. The amount of pigments and flavors can be adjusted at will. Complete the quantitative adding and mixing of flavors, pigments, and acids online;

6. The pouring head has been improved, the pouring quantity is accurate, the replacement and operation of the punch are simple and convenient, and it is individually adjustable. The stroke of the punch (weight of sugar granules) can be adjusted online.

7. The insulation hopper has electric heating control, and the temperature controller PID trapezoidal temperature control is accurate and can be set.

8. The cooling tunnel has been improved. The entire refrigeration machine is assembled in the freezer with a unified height. The length of the tunnel is lengthened and the appearance is beautiful. The cooling effect is better than that shown in the figure and the temperature control is more accurate. This freezer is equipped with a defrost device.

9. The demoulding mechanism adopts our company’s innovative chain structure and is equipped with rotating brushes and air blowers. The three demoulding structures achieve 100% demoulding.

10 The cooling conveyor belt of this soft candy pouring machine uses PU belt, which has a long service life, beautiful appearance, and is easy to clean and maintain. The bottom of the mesh belt adopts a guide rail mechanism, so the conveyor belt will not deform. Non-standard machines can be customized according to customers' site requirements.

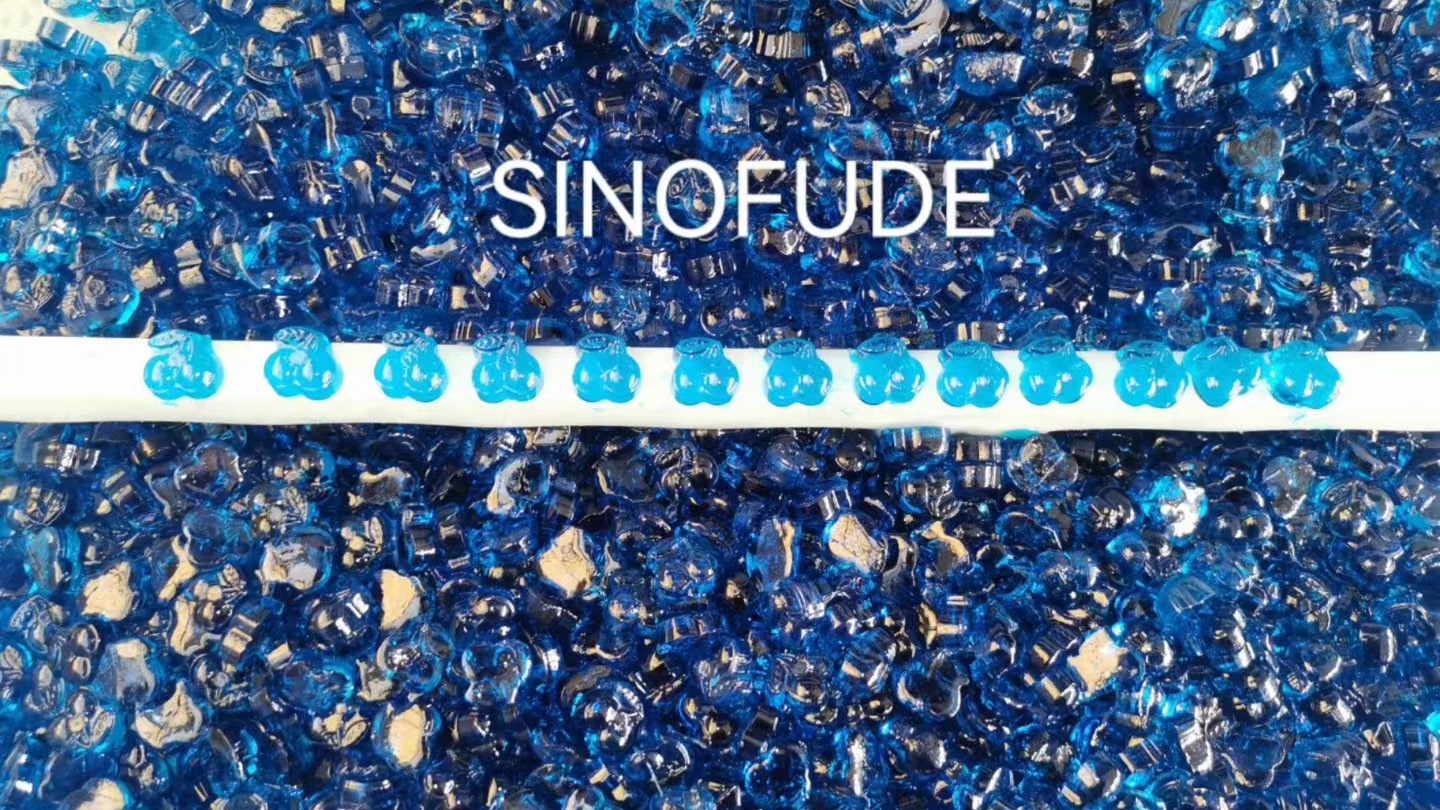

11 Provide different types of molds for producing 2D3D types of candies in different shapes.

12. Adjust the cooking part, device and mold. This production line can produce hard candies, spherical and flat three-dimensional lollipops.

If you’re interested in the gummy candy equipment, please feel free to contact me.

Oue website: https://sinofudegroup.com/

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.