The picture shows the model CBZ500 popping boba machine, CBZ500 production line using PLC and servo control system, automatic processing design. The popping boba production line adopts PLC/ servo process control and built-in touch screen (HMI),which is easy to operate. In addition, Due to the insulation design of depositing hopper and nozzle, the popping boba production line can simultaneously produce popping boba and agar boba.

Parameters of the whole production line:

Model | CBZ500 |

Capacity (kg/h) | Upto 500 |

Depositing stroke (Pcs) | 15-25times |

Chilling Capacity | 10PH |

Length of the whole line (m) | 8-10m |

Electric power needed | 14-40kw |

Compressed air consumption Compressed air pressure | 2m3/min 0.4-0.6 Mpa |

Gross weight (Kgs) | Approx. 3800 |

Boba weight | According to boba diameter(Customized from 3-30mm or more) |

Machine size | 11500x1700x1780mm |

CBZ500 popping boba Production Line

The picture shows the model CBZ500 popping boba machine, CBZ500 production line using PLC and servo control system, automatic processing design. The popping boba production line adopts PLC/ servo process control and built-in touch screen (HMI),which is easy to operate. In addition, Due to the insulation design of depositing hopper and nozzle, the popping boba production line can simultaneously produce popping boba and agar boba.

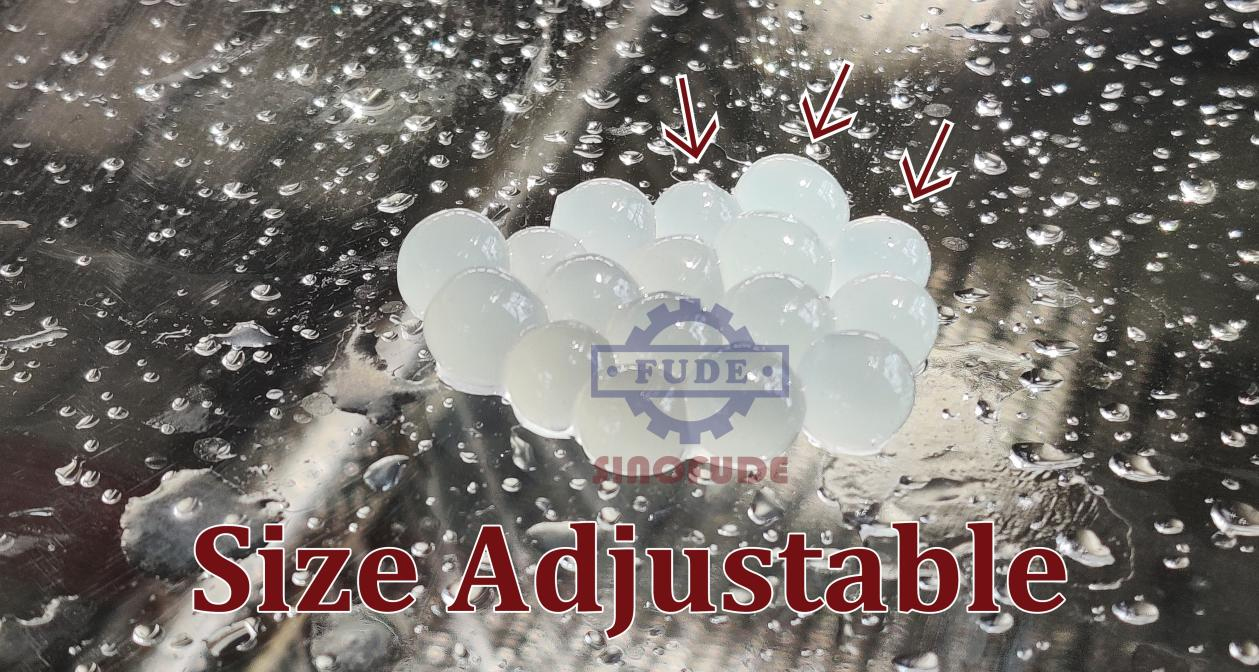

The standard popping boba production capacity range of this line is 400-500kg/h. The main parts of the popping boba production line are made of stainless steel SUS304, also can be customized SUS316. Popping boba production line is specially designed with continuous operation and material recovery device.So this device can avoid the waste of raw materials .By adjusting the depositing machine to adapt to different sizes of popping bobas.

Kitchen system

1. 3-Layers fixed cooker with scrapper stirrer: 2sets

2. Lobe pump for transferring cooked syrup: 4sets

3. Cooling tank with scrapper stirrer: 2sets

4. Electrical control cabinet and skid frame: 1set

Combined with the production process, the popping boba produced by this production line is bright in color, round in shape, beautiful in appearance and delicious in taste. According to the production process, the production line contains three kinds of liquids, which are the jam material liquid (that is, the liquid inside the popping boba), the coagulation liquid (that is, the surface layer of the popping boba, the main component is sodium alginate), and the preservation liquid ( Mainly used to protect the popping boba)

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.