Project spec: 1500 wide 2 tonnes capacity.

How does the automation of a SINOFUDE biscuit production line ensure consistent product quality? How does a biscuit production line adapt to changes in market demand and remain flexible? How does a biscuit line reduce energy consumption and environmental impact, SINOFUDE will tell you the solution project.

Background

Bangladesh Foods client is one of the top three biscuit producers in Bangladesh. The biscuit producer needed to deliver 1000 tonnes of biscuit orders per month, packed in trailer boxes. The biscuit manufacturer needed to develop 5 new biscuit products. Within a period of 11 months they needed to develop, test and operate a new biscuit production line system to develop biscuit recipes that catered for the local market's tastes, with a capacity to produce 2 tonnes of biscuit production line per hour.

Customer Requirements

Project Deadline: Given the tight timeframe, the Bangladeshi client needed a solution provider with the expertise and capability to quickly help design, order, install and test the material handling system. The Bangladeshi client's previous solution provider was unable to complete the project or order the required equipment within the timeframe to achieve such a high throughput.

Cost control: Biscuit production requires large quantities of raw materials and a precise machine capable of saving energy and reducing scrap in finished biscuits. Therefore designing a system to minimise costs and product loss is critical.

Reliability: The fast turnaround nature of the activity and the huge volume of products to be handled required a reliable system that could be easily installed and commissioned. Bangladesh Foods needed a solution provider that would support the entire process and help them through the entire commissioning process. And, it required SINOFUDE to hire a formulator.

Field of Study

This case requires close cooperation between SINOFUDE and Bangladesh company from system biscuit production line design to installation and commissioning. The combination of direct combustion furnace and hot air circulation furnace designed by China SINOFUDE Company will be put into use within 1 month after installation and commissioning, 3 months earlier than the original deadline. The project was successfully completed on time and within budget, increasing the capacity of the SINOFUDE biscuit production line by 2 tons.

SINNOFUDE's solution

Considering the time constraints and project requirements, SINOFUDE creatively found a solution to help the Bangladeshi biscuit factory fulfil its order on time. SINOFUDE's engineering team started with the idea of improving productivity by using automation technology and high-speed processing units throughout the biscuit production line, which allowed for a significant increase in production speed and a reduction in manual labour. This has effectively increased the productivity of the biscuit line, enabling the Bangladeshi company to produce biscuits at a much faster rate than the customer had requested for the line. In addition, SINOFUDE has integrated motor control panels and PLC panels, enabling the Bangladeshi company to manage the system with fewer operators. The entire 2 tonne line can be completed with only 5 employees.

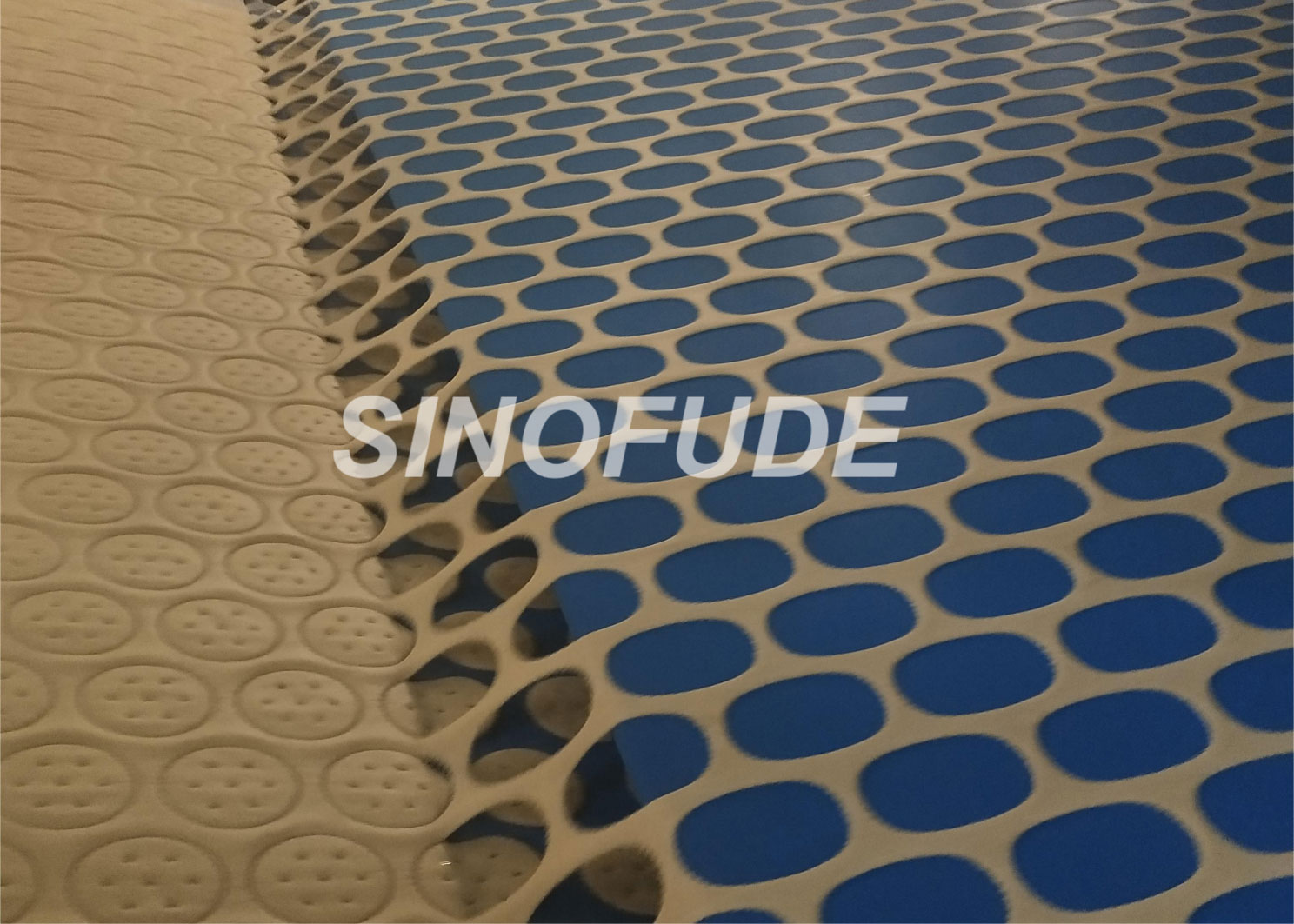

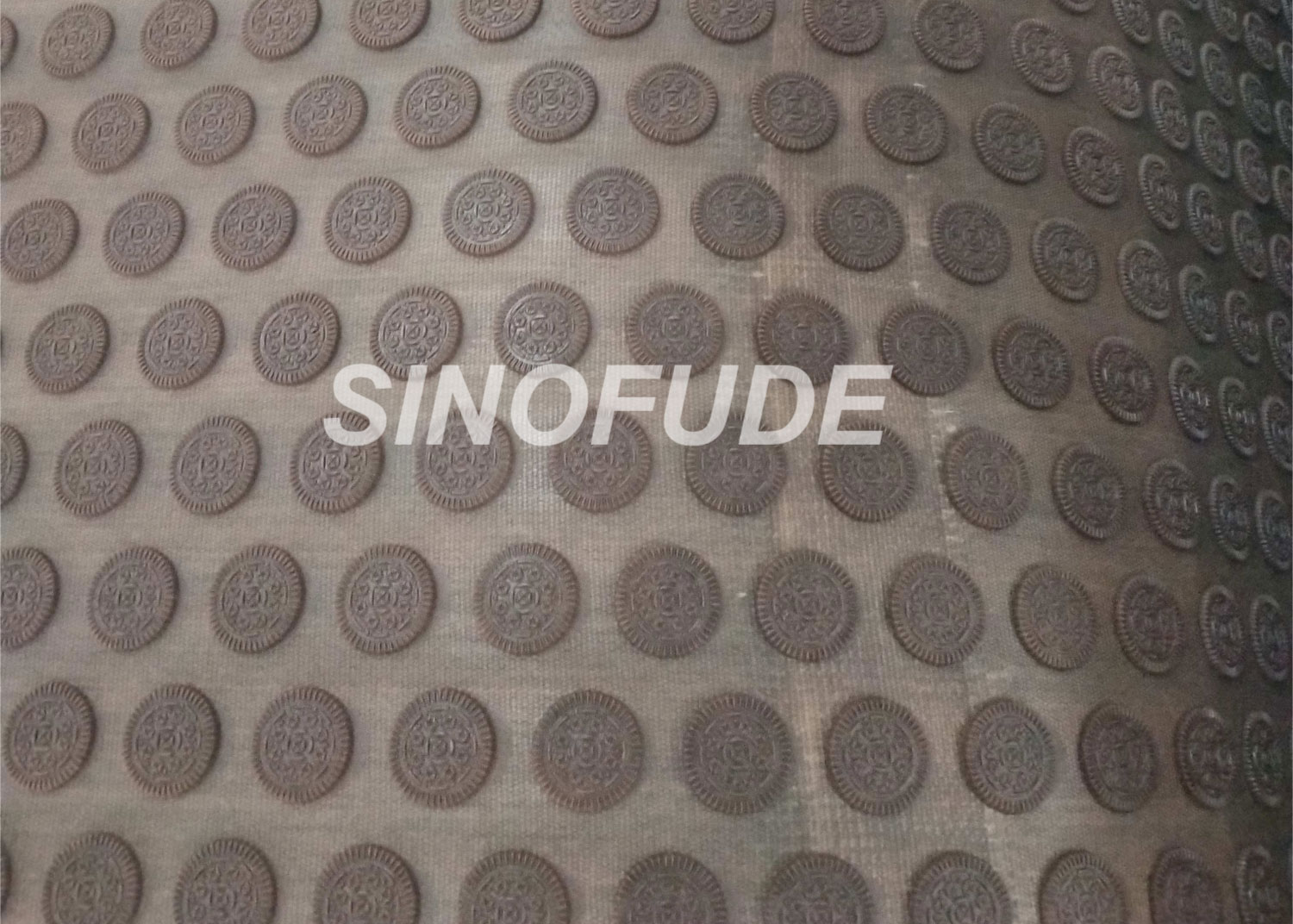

SINOFUDE biscuit lines offer product diversity: SINOFUDE's biscuit lines have flexible configuration options, allowing the production of a wide range of biscuit products in a wide range of flavours, shapes and packages thanks to the dough mixer and the shortening and toughness forming unit, as well as the lifting device of the forming unit. It is possible to switch and customise products easily by changing moulds, dough types, to meet different consumer needs and preferences. For example: shortbread biscuits, tough biscuits, soda biscuits, lye biscuits.

The Bangladeshi company was able to accommodate the increased order size while maintaining the original schedule of the initial order, which resulted in the addition of 10 new biscuit product categories.

The biscuit line solution increased efficiency and reduced manual labour, meaning that the entire process could be carried out by just four or five people.

At the end of the initial order, the Bangladeshi company was only able to produce 500 kg of biscuit products per hour, but now Bangladesh is able to fulfil biscuit orders for 2 tonnes of product. They have partnered with SINOFUDE and are ready to add another 2 tonnes biscuit production line in 2023.

Summary:

Our biscuit production line has the following outstanding features and advantages:

Efficient production: our production line adopts advanced automation technology and high-speed processing device, which can achieve high efficiency biscuit production. It can significantly increase production speed, reduce manual intervention and maintain biscuit consistency and quality.

Guaranteed product quality: The biscuit production line ensures consistent quality standards for each product through precise process control and automation systems. This eliminates human influence on product quality and reduces scrap rates.

Flexibility and versatility: Our biscuit production lines offer excellent flexibility to produce biscuits in a wide range of flavours and shapes. You can easily switch products and adjust to changing market demands. This will help you expand your product line and meet the diverse taste preferences of consumers.

Save on labour costs: An automated biscuit production line reduces the need for manual labour, thereby lowering labour costs. This allows you to utilise human resources in other key areas, improving the overall efficiency of your business.

Environmentally friendly: Modern biscuit production lines focus on environmental protection and sustainability. They use efficient energy utilisation and waste management methods, reducing energy consumption and environmental impact.

Intelligent control systems: our biscuit production lines are equipped with intelligent control systems that monitor and adjust key parameters of the production process in real time. This ensures biscuit production stability and consistency and minimises scrap.

Data tracking and analysis: Some of our advanced biscuit production lines are equipped with data tracking and analysis systems that monitor key parameters in the biscuit production process in real time. This provides valuable data and insights to help you optimise production and make decisions.

Sustainability and environmental friendliness: We focus on environmental protection and design our biscuit production lines with energy efficiency and waste management in mind. We use energy-efficient biscuit equipment and environmentally friendly processes to minimise energy consumption and environmental impact.

Technical support and training: We offer a comprehensive technical support and training programme to ensure that your employees are proficient in operating and maintaining the biscuit production line. Our dedicated team will work closely with you to ensure smooth operation and maximise the benefits of the line.

Together, these advantages enable biscuit production lines to increase productivity, guarantee product quality, provide product variety and gain a competitive edge in a highly competitive market. Choosing the right biscuit production line for your needs will bring long-term benefits and growth to your business.

We are confident that by introducing our biscuit production line, you will be able to achieve higher productivity, better product quality and greater market competitiveness. We invite you to schedule a time to discuss your needs and our solutions further. We look forward to establishing a successful relationship with you.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.