Introduction:Automatic Multifunctional Biscuit Production Line

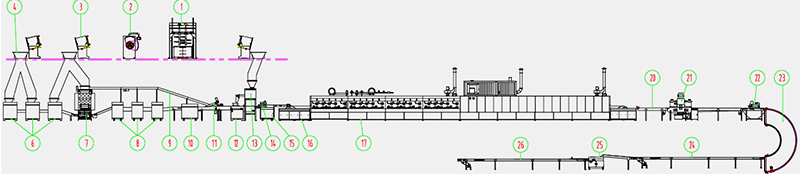

1. Multifunctional biscuit production line

Can produce various types of crisp biscuits, tough biscuits, three-color (sandwich) biscuits, etc.

Machine configuration:

1. Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 4 falling hopper → 5 dough conveyor → 6 feeding machine → 7 laminator → 8 rolling machine → 9 remaining material recovery machine → 10 Roll cutting machine → 11 separator → 12 roll printing machine → 13 crisp powder blanking machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 17 mixed oven (direct-fired oven + hot air Convection circulation oven) → 20 out of the oven → 21 fuel injection machine → 22 vibration spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

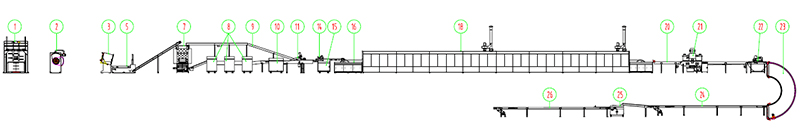

2. Automatic Hard biscuit production line

Can produce various types of hard biscuits such as cracker, soda biscuit, etc.

Machine configuration:

1. Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 5 dough conveyor → 7 laminator → 8 rolling machine → 9 residual material recovery machine → 10 rolling cutter → 11 separator → 14 Spreader → 15 furnace machine → 16 mesh belt drive machine → 18 electric oven → 20 furnace machine → 21 fuel injection machine → 22 vibrating feeder → 23 turning machine → 24 cooling conveyor → 25 star wheel Cake machine → 26 cake picking conveyor

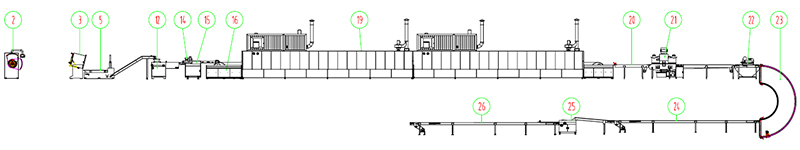

3. Automatic soft biscuit production line

Can produce various types of soft biscuits, like Marie Biscuit, Glucose Biscuit etc.

Machine configuration:

2 horizontal dough mixer → 3 dumper → 5 dough conveyor → 12 roll printing machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 18 hot air convection circulating oven → 20 discharge machine → 21 Fuel injection machine → 22 vibrating spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

Relying on advanced technology, excellent production capabilities, and perfect service, SINOFUDE takes the lead in the industry now and spreads our SINOFUDE all over the world. Together with our products, our services are also supplied to be the highest-level. biscuit manufacturing plant SINOFUDE is a comprehensive manufacturer and supplier of high-quality products and one-stop service. We will, as always, actively provide prompt services such. For more details about our biscuit manufacturing plant and other products, just let us know.SINOFUDE takes great care to ensure the quality of its products. Manufacturing is done in-house, with third-party inspections done to ensure compliance. Special focus is given to the inner components, especially the food trays, which undergo rigorous testing, including chemical release and high-temperature capacity checks. Trust SINOFUDE to provide only the best in terms of quality and safety for your needs.

1. Multifunctional biscuit production line

Can produce various types of crisp biscuits, tough biscuits, three-color (sandwich) biscuits, etc.

Machine configuration:

Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 4 falling hopper → 5 dough conveyor → 6 feeding machine → 7 laminator → 8 rolling machine → 9 remaining material recovery machine → 10 Roll cutting machine → 11 separator → 12 roll printing machine → 13 crisp powder blanking machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 17 mixed oven (direct-fired oven + hot air Convection circulation oven) → 20 out of the oven → 21 fuel injection machine → 22 vibration spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

2. Automatic Hard biscuit production line

Can produce various types of hard biscuits such as cracker, soda biscuit, etc.

Machine configuration:

Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 5 dough conveyor → 7 laminator → 8 rolling machine → 9 residual material recovery machine → 10 rolling cutter → 11 separator → 14 Spreader → 15 furnace machine → 16 mesh belt drive machine → 18 electric oven → 20 furnace machine → 21 fuel injection machine → 22 vibrating feeder → 23 turning machine → 24 cooling conveyor → 25 star wheel Cake machine → 26 cake picking conveyor

3. Automatic soft biscuit production line

Can produce various types of soft biscuits, like Marie Biscuit, Glucose Biscuit etc..

Machine configuration:

2 horizontal dough mixer → 3 dumper → 5 dough conveyor → 12 roll printing machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 18 hot air convection circulating oven → 20 discharge machine → 21 Fuel injection machine → 22 vibrating spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

Model | BBG250 | BBG400 | BBG600 | BBG800 | BBG1000 | BBG1200 | BBG1500 |

Capacity | 50-80kg/H | 100-200kg/H | 200-400kg/H | 400-600kg/H | 600-1000kg/H | 1000-1500kg/H | 1500-2000kg/H |

In essence, a long-standing biscuit manufacturing plant organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the biscuit manufacturing plant, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the biscuit manufacturing plant, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The buyers of biscuit manufacturing plant come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. biscuit manufacturing plant QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.