The gummy candy coating machine is one of the key equipment in the candy production line. It automatically coats the gummy with oil and sugar, giving it a unique taste and appearance. This article will introduce in detail the working principle, characteristics and application of the gummy candy coating machine, as well as its importance in the production of gummy candy.

Introduction of gummy candy coating machine

The gummy candy coating machine is one of the key equipment in the candy production line. It automatically coats the gummy with oil and sugar, giving it a unique taste and appearance. This article will introduce in detail the working principle, characteristics and application of the gummy candy coating machine, as well as its importance in the production of gummy candy.

-Working principle

The oil coating and sugar coating machine adopts a continuous working method and has the following main steps:

Oil coating: The gummy candy enters the machine through the conveying system and is coated with oil through nozzles and rollers, forming a uniform oil film on the surface of the gummy candy.

By adjusting the parameters of the oil coating machine equipment, such as the spraying amount of the nozzle or the rotation speed of the drum, the coating thickness of the grease can be increased or reduced.

Oil type and formula: According to product requirements, different types of oil can be replaced or the formula of oil can be adjusted to achieve the desired taste and appearance effect.

Sugar coating:The gummy candy moistened by steam enters the sugar powder area, and through the action of a drum and a vibrating disc, the surface of the gummy candy is evenly covered with a layer of sugar particles.

By adjusting the speed or amplitude of the drum or vibrating disc, the contact time between the gummy candy and the sugar can be increased or reduced, thereby adjusting the degree of wrapping.

Sugar particle size: According to product requirements, different sizes of sugar particles can be selected to achieve the desired appearance effect. The sugar coating machine is usually equipped with replaceable screens or filters for screening sugar particles of different sizes.

Separation and collection: The coated gummy leaves the machine through the conveying system and enters the subsequent packaging or processing process。

In addition

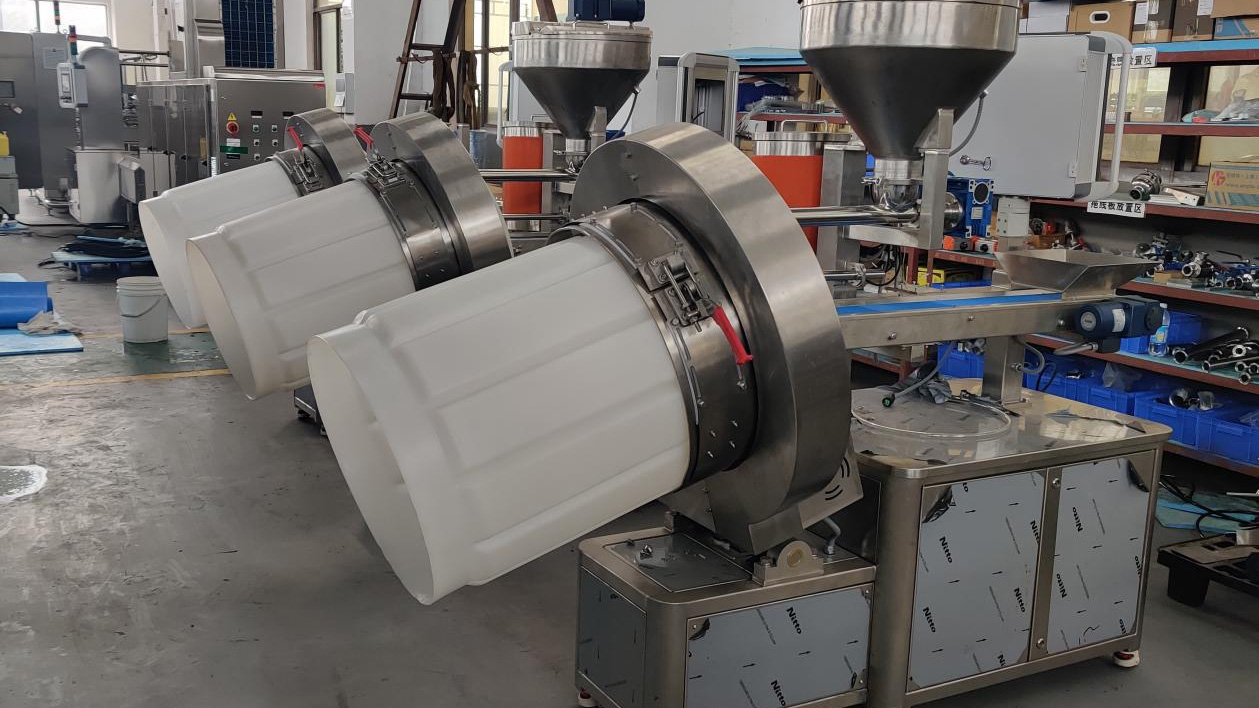

SINOFUDE has independently developed an oil and sugar coating integrated machine. The gummy candy oil and sugar coating integrated machine is a device that integrates oil coating and sugar coating functions, specifically designed for the processing and production of gummy candy. It combines the two key steps of coating gummy candy in oil and sugar, and achieves continuous processing through automation.

The following is an introduction to the all-in-one machine for coating gummy candy with oil and sugar:

Structure and working principle:

The all-in-one machine for coating gummy with oil and coating with sugar usually consists of a conveying system, a oil coating part and a sugar coating part. The gummy enters the machine through the conveying system, and passes through the oil coating part. The oil will be evenly coated on the surface of the gummy. Then the gummy enters the sugar-coated part, and under the action of the roller or vibrating plate, the surface of the gummy is evenly covered with a layer of sugar. Finally, the gummy coated in oil and sugar leaves the machine through a conveyor system and enters subsequent packaging or processing.

Features and Benefits:

Automated operation: The all-in-one machine for coating soft candy in oil and sugar coating realizes fully automated operation, saving manpower and improving production efficiency.

Integrated design: By integrating the oil coating and sugar coating functions into one machine, the production line layout and operation process are simplified.

Flexible adjustment: All-in-one machines usually have adjustable parameters and functions, which can be flexibly adjusted according to different product requirements, such as the thickness of oil coating, the degree of sugar coating, etc.

High quality and consistency: The machine uses a precise control system to ensure that the oil on the surface of the gummy is evenly coated and the sugar is evenly wrapped, so that each gummy has a consistent taste and appearance.

Adjustment of the effect of gummy coated in oil and coated in sugar:

The oil coating and sugar coating parts of the gummy coating, oil coating and sugar coating machine can be adjusted in the following ways:

Adjustment of oil-coated parts:

Coating thickness: All-in-one machines often have adjustable nozzles or rollers that can control the thickness of the oil applied. By adjusting the parameters of the coating equipment, such as the spray volume of the nozzle or the rotation speed of the drum, the coating thickness of the oil can be increased or decreased.

oil type and formula: According to product requirements, different types of oil can be replaced or the formula of the oil can be adjusted to achieve the desired taste and appearance.

Adjustment of the sugar coating part:

Coating: All-in-one machines often have adjustable rollers or vibrating disks that control the degree to which the gummy is coated with sugar. By adjusting the speed or amplitude of the drum or vibrating plate, you can increase or decrease the contact time of the gummy with the sugar, thereby adjusting the degree of coating.

Sugar particle size: Depending on product requirements, sugar particles of different sizes can be selected to obtain the desired appearance. All-in-one machines usually come with replaceable screens or strainers for sifting different sizes of sugar.

When adjusting the oil coating and sugar coating parts, real-time monitoring and adjustment can be made based on product requirements and production experience. Through repeated testing and debugging, the optimal parameters and settings can be found to ensure that the gummies reach consistent standards in quality and appearance.

Plus, SINOFUDE also produces various types of gummy and chocolate coating machines, which are mainly used for surface coating of gummy, chocolate or other similar products. This machine makes full use of syrup, chocolate or other coating materials, and forms a uniform and smooth coating layer on the product surface through precise temperature and speed control.

Working principle:

The working principle of the gummy coating machine is based on the principles of physics and thermodynamics. First, the gummy is placed into a rotating drum. The coating material (such as syrup or chocolate) is then evenly sprayed onto the rotating gummy. By adjusting the temperature and spray speed, the thickness and uniformity of the coating layer can be controlled. During the coating process, the machine will continuously rotate to ensure that each gummy candy is evenly coated.

Main features:

High efficiency: The gummy candy coating machine can process a large number of gummy candies in a short time, significantly improving production efficiency.

Uniform coating: Through precise control, each gummy can be ensured to be evenly coated, improving the appearance quality of the product.

Easy to operate: Most gummy coating machines have intuitive control panels that allow operators to easily adjust parameters.

Easy maintenance: gummy candy coating machines are usually designed with ease of maintenance in mind, and most machines can be easily disassembled and cleaned.

In conclusion

In general, the gummy candy coating machine is an efficient and reliable equipment that plays an important role in the food industry. By using gummy candies and coating machines, manufacturers can produce gummies with various flavors and colors to meet the needs of the market.

SINOFUDE provides various production capacities and semi-automatic and fully automatic machines for you to choose from. Welcome to contact us for the latest information!

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.