End-to-end for gelatin gummies: cooking → mixing → vacuum → servo depositing → cooling → demolding → oiling/sugar sanding → (optional) drying & packaging

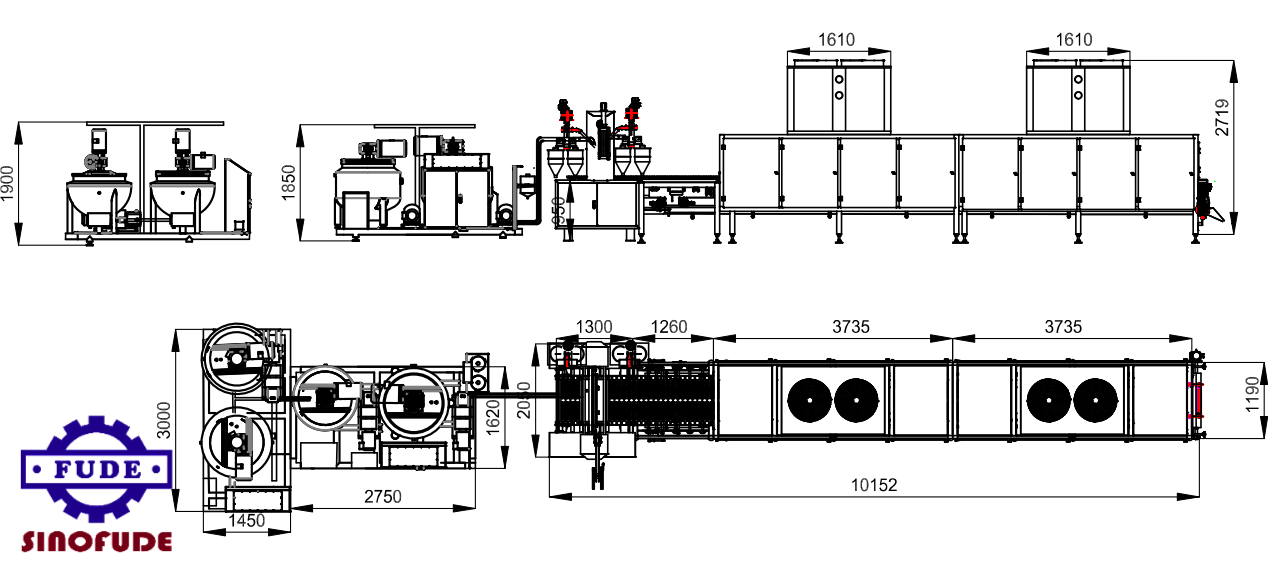

SINOFUDE unveils its next-gen fully automatic gummy line designed for both conventional and functional gelatin gummies. The system features a dual-kettle/dual-tank cooking setup, servo depositing with weight accuracy of ±[1%/0.5–1.0 g per piece], and a multi-zone cooling tunnel with precise temperature control and ample refrigeration capacity. Modular add-ons—demolding, oiling, sugar sanding, drying, packaging—scale from pilot to [150–1000] kg/h.

Key Highlights

· Dual-kettle/dual-tank cooking: parallel/independent heating tailored to gelatin pre-hydration and hot-syrup processing

· Servo depositing: multi-nozzle calibration, weight deviation ≤ ±[1%/0.5–1.0 g per piece]

· Cooling tunnel: multi-zone temperature control, uniformity ±[1–2] °C, total refrigeration capacity [X] kW

· Demolding unit: pre-cool + mechanical flip/ejector/air-assist to raise yield and protect finishes

· Downstream options: oiling (anti-stick/gloss), sugar sanding (texture), linkable with drying/sieving/metal detection/weighing

· Hygiene & Compliance: 304/316L contact parts, CIP/SIP options, compliant with [CE/GMP/HACCP]

· Smart control: PLC+HMI recipes, batch traceability, OEE/energy dashboards (optional)

Process Flow

Sugar/Syrup → Dissolving Kettle A → Concentration Kettle B (vacuum optional) → Gelatin Pre-hydration Tank C → Gelatin Melting/Holding Tank D → Filtration/Vacuum Deaeration → Inline dosing (acid/flavor/color) → Servo Depositing → Multi-zone Cooling Tunnel → Demolding → Oiling/Sugar Sanding → (optional) Static/Fluidized Drying → Checkweigher/Metal Detector → Packaging

Modules

1) Cooking (Dual Kettle/Dual Tank for Gelatin): vacuum/filtration ready, CIP, temperature/solids monitoring.

2) Servo Depositing: multi-axis servo, center-fill/two-color, quick mold change, recipe recall.

3) Cooling Tunnel: multi-zone coils/air circulation, ΔT uniformity ±[1–2] °C, refrigeration [X] kW.

4) Demolding: pre-cool → flip → eject/air-assist → vibration/scraper (per recipe).

5) Downstream: oiling 0.2–0.6% (typical), sugar sanding with adjustable granulation; link with drying/inspection/packaging.

Specifications

| Item | Spec/Unit | Placeholder |

| Capacity Range | kg/h | [150–1000] |

| Depositing Accuracy | g/pc or % | [±0.5–1.0 g / ≤±1%] |

| Refrigeration (Cooling Tunnel) | kW | [X] |

| Temperature Uniformity | °C | [±1–2] |

| Power/Steam | V/Hz/Bar | [380V/50Hz/—Bar] |

| CIP | Yes/No | [Yes/Option] |

| Footprint | m × m | [ X × Y ] |

| Material | — | 304/316L contact parts |

Compliance & Hygiene

304/316L contact material with food-grade seals; one-touch CIP (alkali/acid/hot water/pure water); optional SIP; optional MES/cloud data and batch records.

Applications & Service

Conventional & functional gelatin gummies; shapes: bears/fruits/tablets/custom molds. Packaging: bagging/bottling/sachets with multihead weigher, capping, and labeling. FAT/SAT, commissioning, training and remote diagnostics available.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.