Ọgwụgwụ-na-ọgwụgwụ maka gelatin gummies: nri → ịgwakọta → oghere → servo depositing → jụrụ oyi → imebi → mmanu mmanu / sugar sanding → (nhọrọ) ihicha & nkwakọ ngwaahịa

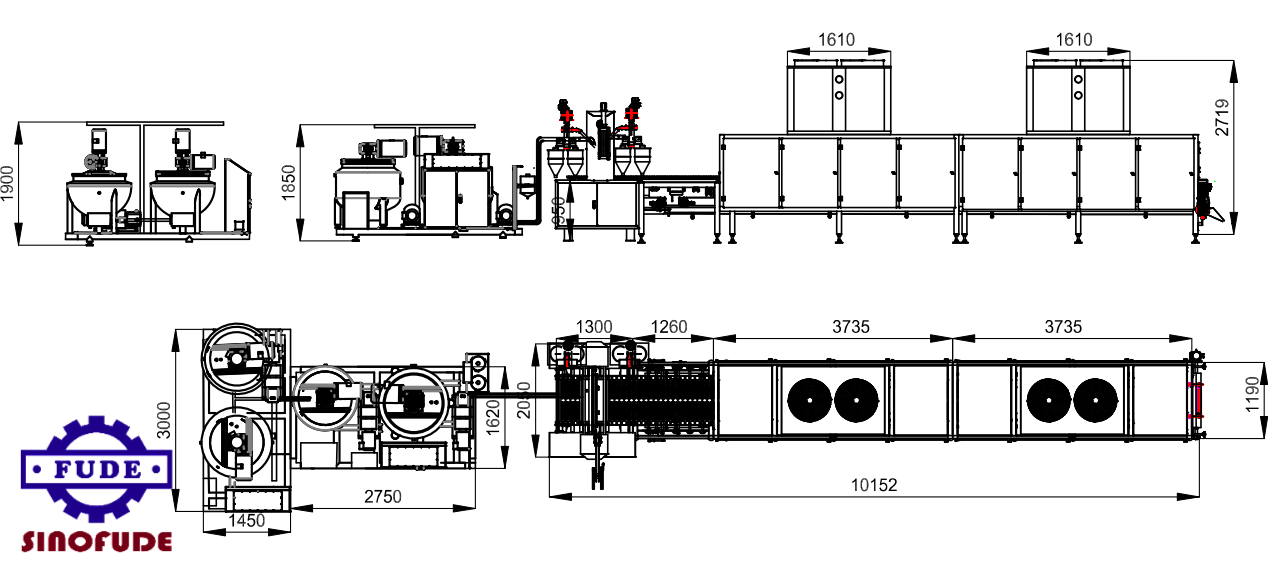

SINOFUDE na-ekpughere ahịrị gummy nke na-esote-gen zuru oke nke emebere maka ma gelatin gummies nke na-arụ ọrụ na nke na-arụ ọrụ. Sistemu ahụ nwere ntọala isi nri nke kettle / okpukpu abụọ, servo na-edobe ya na nha nha nke ±[1%/0.5–1.0 g kwa ibe], yana ọwara jụrụ oyi nke ọtụtụ mpaghara nwere njikwa ọnọdụ okpomọkụ yana oke friji. Ihe mgbakwunye modular—demolding, oiling, sugar sanding, ihicha, nkwakọ ngwaahịa—ọnụ ọgụgụ site na pilot ruo [150–1000] kg/h.

Isi isi

Isi nri nke kettle/kettle nwere okpukpu abụọ: kpo oku n'otu n'otu / nke na-adabere na gelatin tupu hydration na nhazi sirop na-ekpo ọkụ.

Ndokwa nke Servo: nhazigharị ọtụtụ nozzle, ngbanwe ịdị arọ ≤ ± [1%/0.5-1.0 g kwa ibe]

Ọwara jụrụ oyi: njikwa okpomọkụ nke ọtụtụ mpaghara, ịdị n'otu ± [1-2] Celsius C, ikike refrigeration zuru oke [X] kW

· Ngalaba na-emezigharị: tupu oyi + nrụgharị igwe / ejector / ikuku na-enyere aka ibuli mkpụrụ ma chebe mmecha.

Nhọrọ nke ala: mmanu mmanu (mgbochi osisi / gloss), sugar sanding (texture), jikọtara ya na ihicha / sieving / nchọpụta ígwè / ịdị arọ.

· Ịdị ọcha & nnabata: akụkụ kọntaktị 304/316L, nhọrọ CIP/SIP, kwekọrọ na [CE/GMP/HACCP]

Njikwa smart: Ezi ntụziaka PLC+HMI, ogbe traceability, OEE/ike dashboards (nhọrọ)

Usoro Usoro

Sugar/Syrup → Dissolving Kettle A → Concentration Kettle B (nhọrọ agụụ) → Gelatin Pre-hydration Tank C → Gelatin Na-agbaze/Jide Tank D → Filtration/Vacuum Deaeration → Inline dosing (acid/flavor/color) → Servo Depositing → Multi-garm → Ngwọta Obere Sand (nhọrọ) Static/Fluidized Drying → Checkweigher/Metal Detector → Nkwakọ ngwaahịa

Modul

1) Nri (Dual Kettle / Dual Tank maka Gelatin): agụụ / filtration dị njikere, CIP, nlekota okpomọkụ / siri ike.

2) Nkwụnye ego nke Servo: multi-axis servo, etiti-jupụta / agba abụọ, mgbanwe ngwa ngwa ngwa ngwa, cheta ihe nhazi.

3) Ọwara mmiri jụrụ oyi: eriri mpaghara multi-mpaghara / ikuku ikuku, ΔT uniformity ± [1-2] Celsius C, refrigeration [X] kW.

4) Ngosipụta: tupu mma → tụgharịa → eject / ikuku-enyere aka → vibration / scraper (kwa uzommeputa).

5) N'okpuru ala: mmanụ 0.2-0.6% (nke a na-ahụkarị), sugar sanding na nhazi granulation; njikọ na ihicha / nyocha / nkwakọ ngwaahịa.

Nkọwapụta

| Ihe | Spec/Nkeji | Onye njide |

| Oke ikike | n'arọ/h | [150-1000] |

| Ịkwanye nke ọma | g/pc ma ọ bụ % | [± 0.5–1.0 g / ≤±1%] |

| Igwe nju oyi (Ọwara jụrụ oyi) | kW | [X] |

| Ịdị n'otu okpomọkụ | Celsius C | [± 1–2] |

| Ike/Steam | V/Hz/Bar | [380V/50Hz/—Bar] |

| CIP | Ee/Ee e | [Ee/Nhọrọ] |

| Akara ukwu | m × m | [X × Y] |

| Ihe onwunwe | - | 304/316L kọntaktị akụkụ |

Nrube isi na ịdị ọcha

304/316L kọntaktị ihe na nri-ọkwa akara; otu-emetụ CIP (alkali / acid / mmiri ọkụ / mmiri dị ọcha); nhọrọ SIP; Nhọrọ MES/data igwe ojii na ndekọ ogbe.

Ngwa & Ọrụ

Gelatin gummies omenala & arụ ọrụ; ụdị: anụ ọhịa bea / mkpụrụ osisi / mbadamba / omenala ebu. Nkwakọ ngwaahịa: akpa / karama / sachet nwere igwe ihe atụ multihead, capping, na labeling. FAT/SAT, inye ọrụ, ọzụzụ na nyocha dịpụrụ adịpụ dị.

Kpọtụrụ anyị

Naanị hapụ email ma ọ bụ akara ekwentị gị n'ụdị kọntaktị ka anyị wee nye gị ọtụtụ ọrụ!ontact form ka anyị nwee ike ịnye gị ọrụ ndị ọzọ!

Emepụtara ha niile dịka ụkpụrụ mba ụwa siri sie ike. Ngwaahịa anyị enwetala ihu ọma site n'ahịa ụlọ na nke mba ọzọ.

Ha na-ebupụ ugbu a n'ọtụtụ ebe na mba 200.

Nwebiisinka © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Ikike niile echekwabara.