Kumapeto kwa ma gummies a gelatin: kuphika → kusakaniza → vacuum → servo depositing → kuziziritsa → kugwetsa → kuthira mafuta / kuthira mchenga → (posankha) kuyanika & kuyika

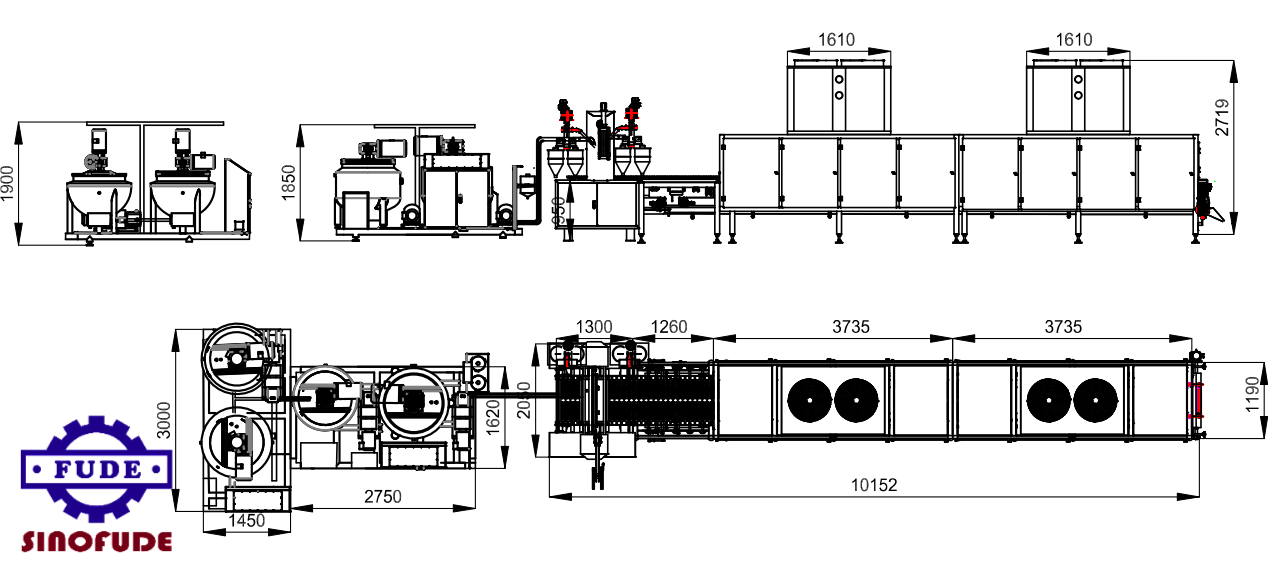

SINOFUDE ivumbulutsa mzere wotsatira wa gummy wopangidwa kuti uzitha kugwira ntchito za gelatin gummies. Dongosololi limakhala ndi ma ketulo awiri-ketulo/awiri-thanki yophikira, kusungitsa servo molingana ndi kulemera kwa ±[1%/0.5-1.0 g pa chidutswa], ndi ngalande yozizirira yamitundu ingapo yokhala ndi kuwongolera bwino kutentha ndi mphamvu yokwanira ya firiji. Zowonjezera zodziyimira pawokha—kugwetsa, kuthira mafuta, kuthira mchenga, kuyanika, kulongedza—kuyambira woyendetsa ndege kufika pa [150–1000] kg/h.

Mfundo Zazikulu

· Kuphika kwa ma ketulo awiri/awiri-thanki: Kutenthetsa kofananira/kodziyimira pawokha kogwirizana ndi gelatin pre-hydration ndi kukonza madzi otentha

· Kuyika kwa Servo: kusanja kwa ma nozzle angapo, kupatuka kwa kulemera ≤ ± [1%/0.5–1.0 g pa chidutswa]

· Msewu wozizirira: kuwongolera kutentha kwa madera ambiri, kufanana ±[1-2] °C, mphamvu ya firiji yonse [X] kW

· Chigawo chowongoleredwa: chozizira chisanakhale + chowongolera makina / ejector / mpweya wothandizira kukweza zokolola ndikuteteza zomaliza

Zosankha zapansi: kuthira mafuta (anti-stick/gloss), mchenga wa shuga (mawonekedwe), olumikizidwa ndi kuyanika / sieving / kuzindikira chitsulo / kuyeza

· Ukhondo & Kutsatira: 304/316L magawo olumikizirana, zosankha za CIP/SIP, zogwirizana ndi [CE/GMP/HACCP]

· Kuwongolera kwanzeru: Maphikidwe a PLC + HMI, kutsatiridwa kwa batch, OEE/madashboard amphamvu (posankha)

Njira Yoyenda

Shuga/Manyowa → Ketulo A Yosungunula → Ketulo B yoyikirapo (mungasankhe) → Tanki C ya Gelatin Pre-hydration → Kusungunuka kwa Gelatin/Kusunga Tanki D → Kusefedwa/Kusokoneza Mpweya → Kuthira pamizere (acid/kukometsera/mtundu) → Kuyika kwa Servo → Kupaka mchenga → Kutentha kwamchenga → Kutentha kwamchenga (posasankha) Kuyanika Kokhazikika/Kumadzimadzi → Checkweigher/Metal Detector → Kupaka

Ma modules

1) Kuphika (Awiri Ketulo / Tanki Yawiri ya Gelatin): vacuum / kusefera okonzeka, CIP, kutentha / zolimba kuwunika.

2) Kuyika kwa Servo: ma multi-axis servo, kudzaza pakati / mitundu iwiri, kusintha kwachangu nkhungu, kukumbukira maphikidwe.

3) Msewu Wozizira: Mapiritsi amitundu yambiri / kufalikira kwa mpweya, ΔT kufanana ± [1-2] °C, firiji [X] kW.

4) Kuwongola: kuziziritsa kale → tembenuzani → tulutsani/kuthandizira mpweya → kugwedera/kupukutira (panjira iliyonse).

5) Mtsinje wapansi: kupaka mafuta 0.2-0.6% (yachibadwa), mchenga wa shuga ndi granulation yosinthika; kulumikizana ndi kuyanika/kuwunika/kuyika.

Zofotokozera

| Kanthu | Spec/Chigawo | Choyimira |

| Mphamvu Range | kg/h | [150-1000] |

| Kusungitsa Kulondola | g/pc kapena% | [±0.5–1.0 g / ≤±1%] |

| Refrigeration (Tonelo Wozizirira) | kW | [X] |

| Kutentha Uniformity | °C | [±1–2] |

| Mphamvu/Nthunzi | V/Hz/Bar | [380V/50Hz/—Bar] |

| CIP | Inde/Ayi | [Inde/Njira] |

| Mapazi | m × m | [X × Y] |

| Zakuthupi | - | 304/316L zolumikizirana |

Kutsata & Ukhondo

304/316L kukhudzana ndi zisindikizo chakudya kalasi; kukhudza kamodzi CIP (alkali / asidi / madzi otentha / madzi oyera); SIP yosankha; MES / data yamtambo ndi zolemba za batch.

Mapulogalamu & Ntchito

Gelatin gummies ochiritsira & ntchito; mawonekedwe: zimbalangondo/zipatso/mapiritsi/zoumba mwachizolowezi. Kupaka: matumba / bottling / matumba okhala ndi choyezera chambiri, cholembera, ndi kulemba. FAT / SAT, kutumiza, maphunziro ndi zowunikira zakutali zomwe zilipo.

Lumikizanani Nafe

Ingosiyani imelo kapena nambala yanu yafoni pa fomu yolumikizirana kuti tikupatseni ntchito zambiri! funsani fomu kuti tikupatseni ntchito zambiri!

Onse amapangidwa motsatira mfundo zokhwima zapadziko lonse lapansi. Zogulitsa zathu zalandira chiyanjo kuchokera kumisika yapakhomo ndi yakunja.

Tsopano akutumiza kwambiri kumayiko 200.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Ufulu Onse Ndiotetezedwa.