Kupera-ku-kuguma kwegelatin gummies: kubika → kusanganisa → vacuum → servo depositing → kutonhora → kudhiza → kuisa mafuta / shuga jecha → (kusarudza) kuomesa & kurongedza

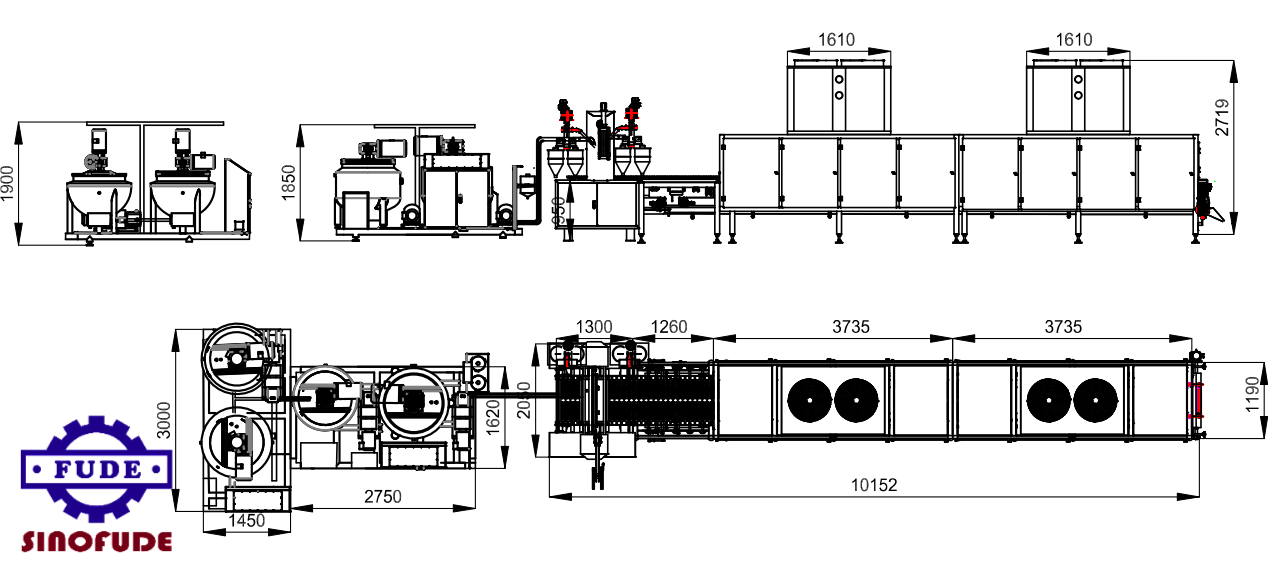

SINOFUDE inovheneka yayo inotevera-gen yakazara otomatiki gummy mutsara wakagadzirirwa ese akajairwa uye anoshanda gelatin gummies. Iyo sisitimu ine mbiri-kettle / mbiri-tangi yekubikira setup, servo inoisa nehuremu hwe ±[1%/0.5-1.0 g pachidimbu], uye yakawanda-zone yekutonhodza tunnel ine chaiyo tembiricha yekudzora uye yakakwana yefiriji kugona. Modular add-ons—demolding, oiling, sugar jecha, kuomesa, kurongedza—chiyero kubva pamutyairi wendege kusvika [150–1000] kg/h.

Pfungwa Huru

· Dual-kettle / mbiri-tangi yekubika: yakafanana / yakazvimirira kupisa yakarongedzerwa kune gelatin pre-hydration uye inopisa-syrup kugadzirisa.

· Servo depositing: yakawanda-nozzle calibration, uremu kutsauka ≤ ± [1%/0.5–1.0 g pachidimbu]

· Mugero wekutonhodza: multi-zone tembiricha kutonga, kufanana ±[1–2] °C, yakazara firiji simba [X] kW

· Demolding unit: pre-inotonhorera + mechanic flip/ejector/air-inobatsira kusimudza goho uye kudzivirira kupera.

Sarudzo dzepasi pemvura: kuzora mafuta (anti-stick / gloss), jecha reshuga (magadzirirwo), inobatanidzwa nekuomesa / sieving / simbi kuona / kuyera

Utsanana & Kutevedza: 304/316L yekuonana zvikamu, CIP/SIP sarudzo, zvinoenderana ne [CE/GMP/HACCP]

* Kudzora kwakangwara: PLC + HMI mabikirwo, batch traceability, OEE / simba dhibhodhi (sarudzo)

Process Flow

Shuga/Sirapu → Keturo A inonyunguduka → Keturo B inonyunguduka (vacuum inosarudza) → Gelatin Pre-hydration Tangi C → Gelatin Inonyunguduka/Kubata Tangi D → Kunyunguduka/Kunyunguduka kweVacuum → Inline dosing (asidhi/kunhuwirira/ruvara) → Servo Depositing → Mugero wejecha → Mushonga Wakawanda → Mushonga Wejecha (kusarudza) Kuomesa / Kuomesa Kuomesa → Checkweigher/Metal Detector → Packaging

Modules

1) Kubika (Dual Kettle / Dual Tangi yeGelatin): vacuum / filtration yakagadzirira, CIP, tembiricha / solids monitoring.

2) Servo Depositing: multi-axis servo, yepakati-kuzadza / maviri-ruvara, nekukurumidza mold shanduko, resipi rangarira.

3) Inotonhorera Tunnel: multi-zone coils / air circulation, ΔT kufanana ± [1-2] °C, firiji [X] kW.

4) Demolding: pre-cool → flip → eject/air-assist → vibration/scraper (per resipi).

5) Kudzika pasi: oiling 0.2-0.6% (yakajairika), shuga sanding nekugadzirisa granulation; link nekuomesa/kuongorora/kurongedza.

Zvinotsanangurwa

| Item | Spec/Chikwata | Nzvimbo |

| Capacity Range | kg/h | [150–1000] |

| Depositing Accuracy | g/pc kana % | [±0.5–1.0 g / ≤±1%] |

| Firiji (Kutonhodza Tunnel) | kW | [X] |

| Tembiricha Uniformity | °C | [±1–2] |

| Simba/Steam | V/Hz/Bar | [380V/50Hz/—Bara] |

| CIP | Hongu/Kwete | [Hongu/Sarudzo] |

| Footprint | m × m | [ X × Y] |

| Material | - | 304/316L yekuonana zvikamu |

Kuteerera & Hutsanana

304/316L yekubata zvinhu zvine chikafu-giredhi zvisimbiso; imwe-touch CIP (alkali / acid / mvura inopisa / mvura yakachena); Optional SIP; inosarudzika MES/gore data uye batch marekodhi.

Zvishandiso & Sevhisi

Yakajairika & inoshanda gelatin gummies; maumbirwo: mapere/michero/mapiritsi/custom molds. Packaging: bhegi / bhodhoro / masacheti ane multihead weigher, capping, uye kunyora. FAT / SAT, kutumwa, kudzidziswa uye kure diagnostics iripo.

Bata Nesu

Ingosiya email yako kana nhamba yefoni pafomu rekuonana kuti tikupe mamwe masevhisi!ontact fomu kuti tikupe mamwe masevhisi!

Zvose zvinogadzirwa maererano nemitemo yakasimba yenyika. Zvigadzirwa zvedu zvakawana nyasha kubva kumisika yemukati neyekunze.

Pari zvino vari kuendesa kunze kwenyika zvakanyanya ku200 nyika.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.