End-to-end kanggo gelatin gummies: masak → nyampur → vakum → servo depositing → cooling → demolding → oiling/sanding gula → (opsional) pengeringan & pengemasan

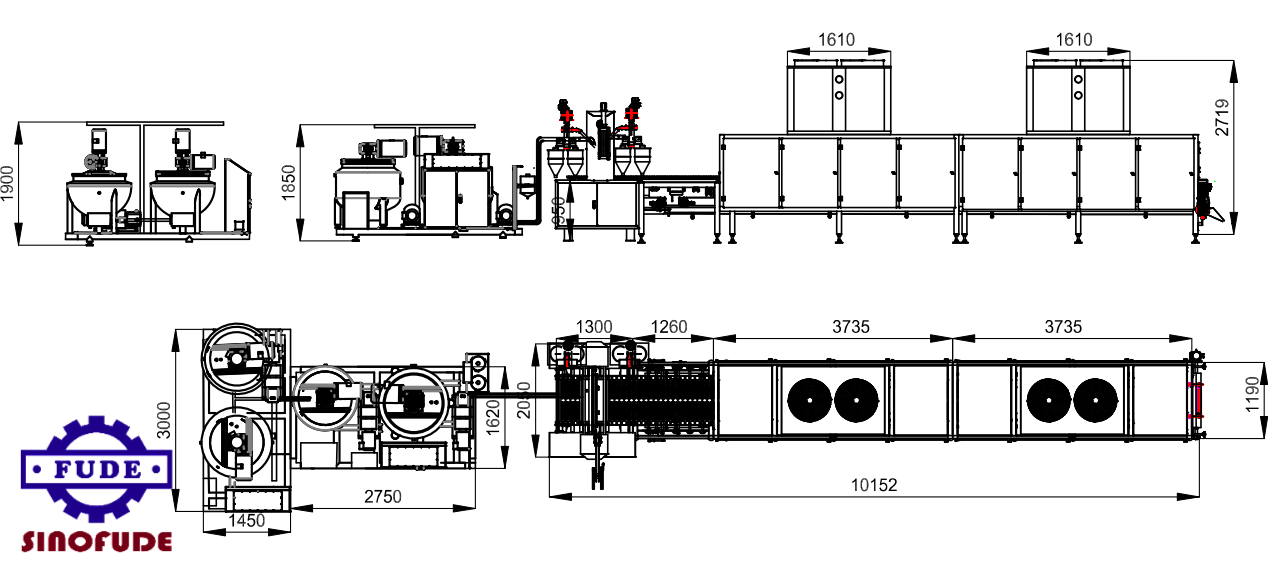

SINOFUDE mbukak garis gummy otomatis generasi sabanjure sing dirancang kanggo gummies gelatin konvensional lan fungsional. Sistem kasebut nduweni persiyapan masak dual-ketel/dual-tank, servo depositing kanthi akurasi bobot ± [1%/0.5-1.0 g saben potong], lan terowongan pendingin multi-zona kanthi kontrol suhu sing tepat lan kapasitas kulkas sing akeh. Tambahan modular-demolding, oiling, pengamplasan gula, pangatusan, kemasan-skala saka pilot nganti [150-1000] kg/jam.

Sorotan Utama

· Masak ketel ganda/dwi-tank: pemanasan paralel/mandiri sing disesuaikan karo pra-hidrasi gelatin lan pangolahan sirup panas

· Servo depositing: multi-nozzle kalibrasi, bobot deviasi ≤ ± [1%/0.5–1.0 g saben potong]

· Terowongan pendingin: kontrol suhu multi-zona, keseragaman ±[1–2] °C, total kapasitas pendinginan [X] kW

· Unit demolding: pra-cool + flip mekanik / ejector / bantuan udara kanggo ngunggahake asil lan nglindhungi finish

· Pilihan hilir: oiling (anti-stick/gloss), pengamplasan gula (tekstur), bisa disambungake karo pangatusan/ayak/deteksi logam/timbangan

· Kebersihan & Kepatuhan: Bagian kontak 304/316L, opsi CIP/SIP, tundhuk karo [CE/GMP/HACCP]

· Kontrol cerdas: resep PLC+HMI, ketertelusuran batch, dasbor OEE/energi (opsional)

Alur Proses

Gula/Sirup → Ketel Pelarut A → Ketel Konsentrasi B (opsional vakum) → Tangki Pra-hidrasi Gelatin C → Tangki Peleburan Gelatin/Tahan D → Deaerasi Filtrasi/Vakum → Dosis inline (asam/rasa/warna) → Servo Depositing → Multi-zone Sulding Tunnel Pengeringan Statis/Fluidized → Checkweigher/Detektor Logam → Kemasan

Modul

1) Masak (Dual Kettle/Dual Tank kanggo Gelatin): vakum/filtrasi siap, CIP, suhu/padatan ngawasi.

2) Servo Depositing: multi-axis servo, tengah-isi / loro-werna, owah-owahan jamur cepet, kelingan resep.

3) Terowongan Pendingin: gulungan multi-zona / sirkulasi udara, keseragaman ΔT ± [1-2] °C, pendinginan [X] kW.

4) Demolding: pre-cool → flip → eject/air-assist → geter/scraper (saben resep).

5) Hilir: oiling 0.2-0.6% (khas), sanding gula kanthi granulasi sing bisa diatur; link karo pangatusan / pengawasan / packaging.

Spesifikasi

| Item | Spesifikasi / Unit | Placeholder |

| Kapasitas Range | kg/jam | [150–1000] |

| Akurasi simpenan | g/pc utawa % | [±0,5–1,0 g / ≤±1%] |

| Pendinginan (Terowongan Pendingin) | kW | [X] |

| Keseragaman Suhu | °C | [±1–2] |

| Daya / Uap | V/Hz/Bar | [380V/50Hz/—Bar] |

| CIP | Ya / Ora | [Ya/Pilihan] |

| tapak sikil | m × m | [ X × Y ] |

| Bahan | — | 304/316L bagean kontak |

Compliance & Hygiene

304/316L materi kontak karo segel pangan-bahan; CIP siji-tutul (basa / asam / banyu panas / banyu murni); SIP opsional; opsional MES / data maya lan cathetan kumpulan.

Aplikasi & Layanan

gummies gelatin konvensional & fungsional; wangun: bruwang / woh-wohan / tablet / cetakan adat. Kemasan: tas / botol / sachet kanthi timbangan multihead, capping, lan label. FAT / SAT, komisioning, pelatihan lan diagnostik remot kasedhiya.

Hubungi Kita

Mung ninggalake email utawa nomer telpon ing formulir kontak supaya kita bisa nyedhiyani sampeyan karo layanan liyane!ontact formulir supaya kita bisa nyedhiyani sampeyan karo layanan liyane!

Kabeh mau diprodhuksi miturut standar internasional sing paling ketat. Produk kita wis nampa sih saka pasar domestik lan manca.

Dheweke saiki akeh ngekspor menyang 200 negara.

Hak Cipta © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Kabeh Hak Dilindungi.