ʻO ka hopena a hiki i ka hopena no ka gelatin gummies: kuke → hui ʻana → vacuum → waiho ʻana i ka servo → hoʻoluʻu → hoʻoheheʻe ʻia → ʻaila ʻaila/paʻa kō → (koho) hoʻomaloʻo a hoʻopaʻa.

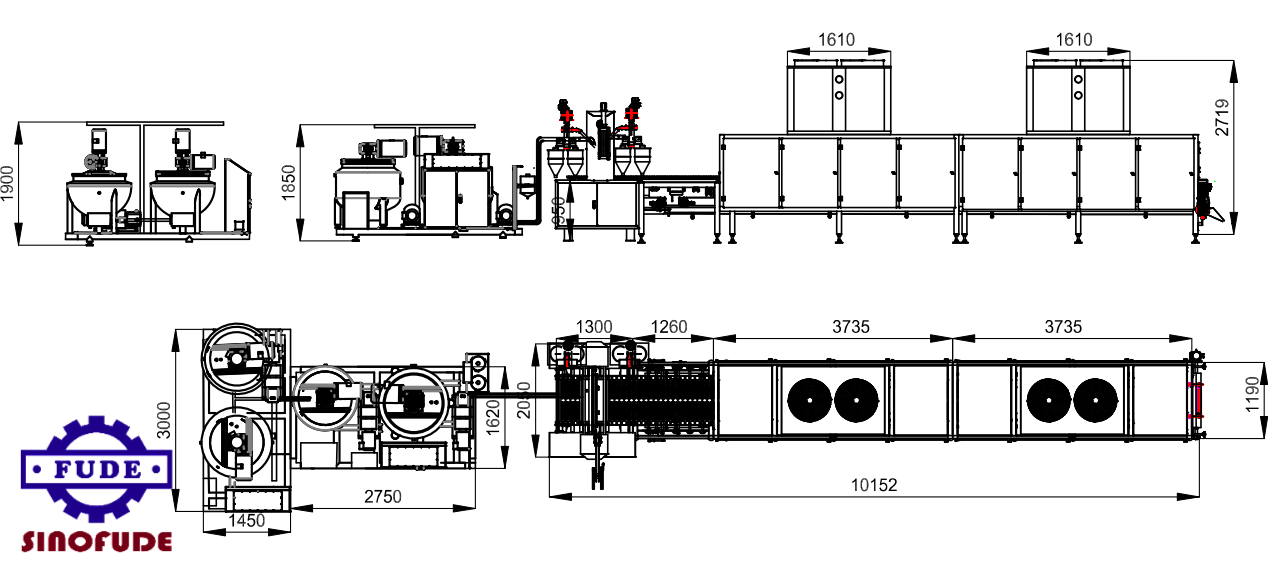

Hōʻike ʻo SINOFUDE i kāna laina gummy ʻakomi holoʻokoʻa i hoʻolālā ʻia no nā gummies gelatin maʻamau a me ka hana. Hōʻike ka ʻōnaehana i kahi hoʻonohonoho kuke kuke ʻelua-kettle/dual-tank, waiho ʻana i ka servo me ka pololei o ke kaumaha o ± [1%/0.5–1.0 g no kēlā me kēia ʻāpana], a me kahi pūnana hoʻoluʻu multi-zone me ka mana kūpono o ka mahana a me ka nui o ka pahu hau. Nā mea hoʻohui modular—demolding, hinu ʻaila, sanding sugar, maloʻo, hoʻopaʻa ʻana—ka unahi mai ka pailaka a hiki i [150–1000] kg/h.

Nā mea nui

· Ke kuke ʻelua-kettle/ʻelua-tank: hoʻomehana like/kūʻokoʻa i hoʻohālikelike ʻia i ka gelatin pre-hydration a me ka hana wela-syrup.

· Ka waiho ʻana o Servo: ka hoʻoponopono ʻana i ka nui-nozzle, hoʻokaʻawale kaumaha ≤ ± [1%/0.5–1.0 g i kēlā me kēia ʻāpana]

· Ahu hoʻoluʻu: ka hoʻomalu ʻana i ka wela o nā ʻāpana he nui, kūlike ± [1–2] °C, ka nui o ka mana hoʻoheheʻe [X] kW

· Hoʻokuʻu i ka ʻāpana: pre-cool + mechanical flip/ejector/air-assist e hoʻonui i ka hua a pale i ka pau

· Nā koho i lalo: ka ʻaila ʻaila (anti-stick/gloss), sanding sugar (texture), hiki ke hoʻopili ʻia me ka hoʻomaloʻo/sieving/ʻike metala/kaumaha.

· Hoʻomaʻemaʻe a me ka hoʻokō: 304/316L mau ʻāpana pili, nā koho CIP/SIP, hoʻokō me [CE/GMP/HACCP]

· Ka mana akamai: PLC+HMI mea hoʻomaʻamaʻa, puʻupuʻu traceability, OEE/ʻenehana dashboards (koho)

Kaʻina Hana

Sugar/Syrup → Dissolving Kettle A → Concentration Kettle B (vacuum koho) → Gelatin Pre-hydration Tank C → Gelatin Melting/Holding Tank D → Filtration/Vacuum Deaeration → Inline dosing (acid/flavor/color) → Servo Depositing → Multi-zone Cooling Tunnel Hoʻomaloʻo Static/Fluidized → Checkweigher/Metal Detector → Packaging

Modules

1) Ke kuke ʻana (Dual Kettle/Dual Tank for Gelatin): hoʻomaʻamaʻa ʻia ka ʻāwīwī / kānana, CIP, ka nānā ʻana i ka mahana / paʻa.

2) Servo Depositing: multi-axis servo, kikowaena-hoʻopiha / ʻelua kala, hoʻololi wikiwiki, hoʻomanaʻo hoʻomanaʻo.

3) Tunnel Hoʻoluʻu: multi-zone coils/air circulation, ΔT uniformity ±[1-2] °C, refrigeration [X] kW.

4) Hōʻike: pre-cool → flip → eject/air-assist → vibration/scraper (no ka meaʻai).

5) Ma lalo o ke kahawai: ka ʻaila 0.2–0.6% (maʻamau), ke one kō me ka granulation hiki ke hoʻololi; loulou me ka hoʻomaloʻo/nānā/packaging.

Nā kikoʻī

| 'ikamu | Spec/Uiuna | Mea kūʻai |

| Kaulana Hiki | kg/h | [150–1000] |

| Waiho pololei | g/pc a i ʻole % | [±0.5–1.0 g / ≤±1%] |

| ʻO ka pahu hau | kW | [X] |

| Kaulike Mahana | °C | [±1–2] |

| Mana/Mahu | V/Hz/Paa | [380V/50Hz/—Paa] |

| CIP | ʻAe/ʻAʻole | [Ae/koho] |

| kapuaʻi wāwae | m × m | [ X × Y ] |

| Mea waiwai | — | 304/316L mau ʻāpana pili |

Hoʻokō & Hoʻomaʻemaʻe

304/316L mea pili me nā hōʻailona meaʻai; hoʻokahi-pā CIP (alkali / acid / wai wela / wai maʻemaʻe); SIP koho; ʻikepili MES/cloud koho a me nā moʻolelo pūʻulu.

Nā noi a me ka lawelawe

ʻO nā gummies gelatin maʻamau a me ka hana; nā ʻano: bea / huaʻai / papa / ʻano maʻamau. Packaging: ʻeke ʻeke/bottleling/sachets me ka multihead weigher, capping, a me ka lepili. Loaʻa ka FAT/SAT, ke kōmike ʻana, ke aʻo ʻana a me nā diagnostics mamao.

E launa me makou

E waiho wale i kāu leka uila a i ʻole helu kelepona ma ka palapala hoʻopili i hiki iā mākou ke hāʻawi iā ʻoe i nā lawelawe hou aku!

Hana ʻia lākou a pau e like me nā kūlana honua koʻikoʻi. Ua loaʻa i kā mākou huahana ke aloha mai nā mākeke kūloko a me nā ʻāina ʻē.

Ke lawe nui nei lākou i nā ʻāina he 200 i kēia manawa.

Kuleana kope © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Ua mālama ʻia nā kuleana āpau.