Xaus-rau-kawg rau gelatin gummies: ua noj → sib tov → nqus → servo depositing → txias → demolding → oiling/qab zib sanding → (yeem) ziab & ntim

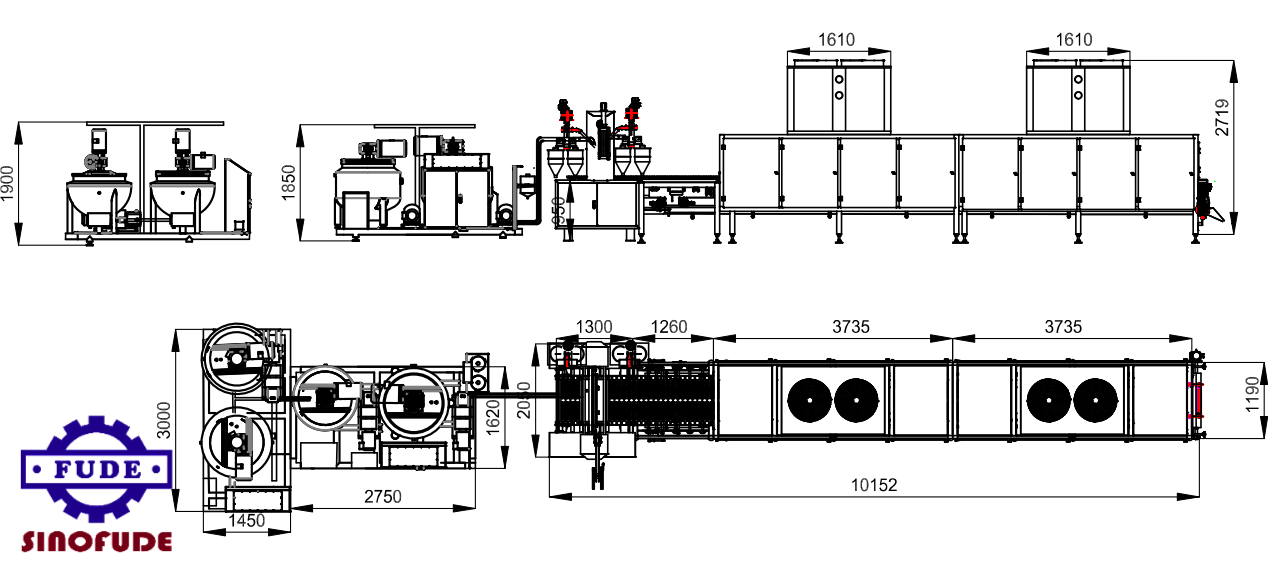

SINOFUDE nthuav tawm nws qhov txuas ntxiv-gen tag nrho tsis siv neeg gummy kab tsim rau ob qho tib si cov pa thiab ua haujlwm gelatin gummies. Lub kaw lus nta ob lub raj mis / ob lub tank ua noj ua haus, servo tso nrog qhov hnyav ntawm ± [1% / 0.5-1.0 g ib thooj], thiab ntau qhov chaw txias txias nrog kev tswj qhov kub thiab txias thiab muaj peev xwm txaus. Modular add-ons - demolding, oiling, qab zib sanding, ziab, ntim - nplai los ntawm kev tsav mus rau [150-1000] kg / h.

Cov ntsiab lus tseem ceeb

· dual-khoov/dual-tank ua noj: parallel/ywj siab cua sov tailored rau gelatin pre-hydration thiab kub-syrup ua

servo depositing: multi-nozzle calibration, qhov hnyav sib txawv ≤ ± [1% / 0.5–1.0 g ib thooj]

Lub qhov txias txias: ntau thaj chaw kub tswj, sib xws ± [1–2] ° C, tag nrho cov tub yees muaj peev xwm [X] kW

· Demolding chav tsev: ua ntej txias + mechanical flip / ejector / cua-pab txhawb nqa tawm thiab tiv thaiv tiav

· Cov kev xaiv hauv qab: oiling (anti-stick / gloss), qab zib sanding (kev ntxhib los mos), txuas nrog ziab / sieving / nrhiav hlau / hnyav

· Hygiene & Ua raws li: 304/316L tiv tauj qhov chaw, CIP / SIP xaiv, ua raws li [CE/GMP/HACCP]

· Ntse tswj: PLC + HMI zaub mov txawv, batch traceability, OEE / lub zog dashboards (yeem)

Txheej Txheem Flow

Qab Zib / Syrup → Dissolving Kettle A → Concentration Kettle B (nqus yeem) → Gelatin Pre-hydration Tank C → Gelatin Melting / Tuav Tank D → Lim / Nqus Deaeration → Inline dosing (acid / flavour / xim) → Servo Depositing / Tshav kub → Multi-Sanding → Oiling → (yeem) Static/Fluidized Drying → Checkweigher/Metal Detector → Ntim

Cov qauv

1) Ua noj (Dual Kettle / Dual Tank rau Gelatin): lub tshuab nqus tsev / lim npaj, CIP, ntsuas kub / khoom.

2) Servo Depositing: multi-axis servo, nruab nrab-sau / ob-xim, hloov pwm ceev, daim ntawv qhia rov qab.

3) Lub qhov txias txias: ntau thaj chaw coils / cua ncig, ΔT uniformity ± [1–2] ° C, tub yees [X] kW.

4) Demolding: pre-txias → tig → eject/air-pab → vibration/scraper (ib daim ntawv qhia).

5) Downstream: oiling 0.2-0.6% (ib txwm), qab zib sanding nrog adjustable granulation; txuas nrog ziab / tshuaj xyuas / ntim.

Specifications

| Yam khoom | Spec / Unit | Qhov chaw |

| Peev Xwm Ntau | kg/h | [150–1000] |

| Depositing raug | g/pc los yog % | [± 0.5–1.0 g / ≤ ± 1%] |

| Tub yees (Coling Tunnel) | kW | [X] |

| Temperature Uniformity | °C | [± 1–2] |

| Lub zog / Chav | V/Hz/Bar | [380V / 50Hz / —Bar] |

| CIP | Yog/Tsis yog | [Yog/Option] |

| Hneev taw | m × m | [X × Y] |

| Khoom siv | — | 304/316L tiv tauj qhov chaw |

Kev Ua Raws Cai & Kev Nyab Xeeb

304/316L cov ntaub ntawv tiv tauj nrog cov khoom noj-qib ntsaws ruaj ruaj; ib kov CIP (alkali / acid / dej kub / dej ntshiab); xaiv tau SIP; xaiv tau MES / huab cov ntaub ntawv thiab cov ntaub ntawv batch.

Daim Ntawv Thov & Kev Pabcuam

Pa & ua haujlwm gelatin gummies; cov duab: bears / txiv hmab txiv ntoo / ntsiav tshuaj / kev cai pwm. Ntim: hnab ntim / ntim / ntim hnab nrog ntau lub taub hau hnyav, capping, thiab daim ntawv lo. FAT/SAT, commissioning, kev cob qhia thiab tej thaj chaw deb diagnostics muaj.

Hu rau peb

Cia li tso koj tus email lossis tus lej xov tooj ntawm daim foos tiv tauj kom peb tuaj yeem muab kev pabcuam ntxiv rau koj!ontact form yog li peb tuaj yeem muab kev pabcuam rau koj ntxiv!

Lawv txhua tus tsim raws li cov qauv nruj tshaj plaws thoob ntiaj teb. Peb cov khoom tau txais kev pom zoo los ntawm kev lag luam hauv tsev thiab txawv teb chaws.

Tam sim no lawv tau dav xa tawm mus rau 200 lub teb chaws.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.