After years of solid and rapid development, SINOFUDE has grown into one of the most professional and influential enterprises in China. gummy manufacturing equipment SINOFUDE is a comprehensive manufacturer and supplier of high-quality products and one-stop service. We will, as always, actively provide prompt services such. For more details about our gummy manufacturing equipment and other products, just let us know.The food can be preserved for a long time. This has been proved by our customers who use this product for over 2 years.

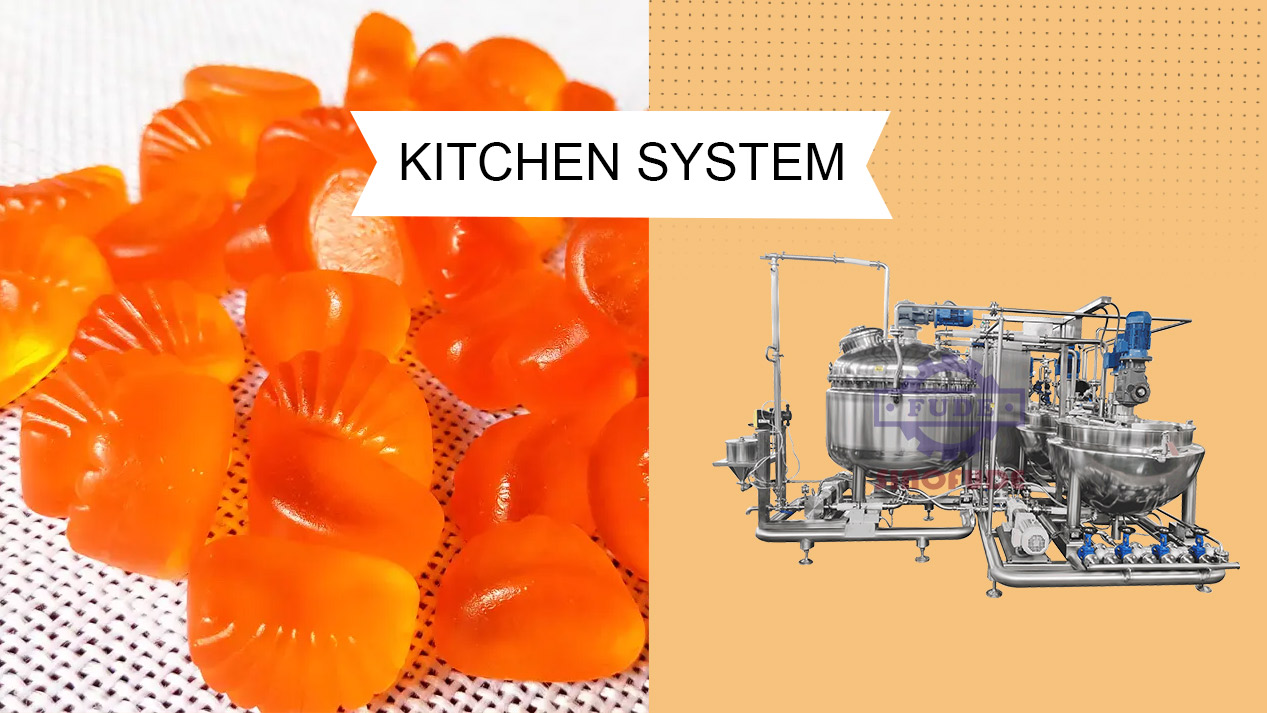

CLM600 Gummy Candy Production line

This machine line is an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied. This depositing line consists of jacket dissolving cooker, gear pump, storage strainer, storage tank, discharging pump, color & flavor jigger, color & flavor mixer, cooling tunnel, electric control cabinet, etc.

CLM600 compact gummy candy production line capacity up to 600kg/per hour, It easily making various flavors of gummies candies.

CLM600 gummy making machine, 200,000pcs gummy candy per hour, 600kg/h

Kitchen system

Jacketed kettle can simply dissolve various raw materials to achieve a fully and efficiently mixed state, which the step will get the syrup.

It can be used to cook candy syrup, dissolve gelatin, and store the syrup to guarantee continuous working.

Pectin☑ Gelatin

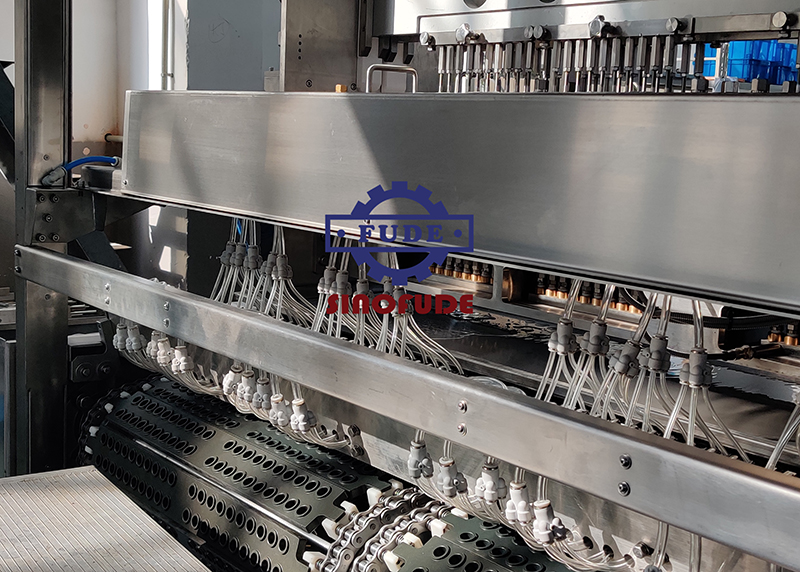

Depositing and cooling Unit

The system is completely intelligently controlled, and the syrup is evenly dripped into the mold cavity. candies with molds will automatically transferred to the cooling system to achieve solidification at a low temperature, and finally demolded.

Depositing unit

1. Servo depositing

2. Automatic oil spraying system,

3. Automatic demoulding.

4. Color and flavor-adding system .

5. Cooling system

Molds

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.