At SINOFUDE, technology improvement and innovation are our core advantages. Since established, we have been focusing on developing new products, improving product quality, and serving customers. gummy making machine We will do our best to serve customers throughout the whole process from product design, R&D, to delivery. Welcome to contact us for further information about our new product gummy making machine or our company.The whole production process of SINOFUDE is under real-time monitor and quality control. It has gone through various quality tests including a test on materials used in the food trays and a high temperature withstanding test on parts.

The industrial electromechanical semi-automatic gummy depositing machine has a strong build and powerful system to accurately and consistently deposit multiple types of gummy candies. It can maintain a high speed, making it ideal for simultaneous deposits. This gummy depositing machine guarantees superior gummy quality and consistency, and its ability to create 2D or full-form 3D solid, striped, layered, and filled confectionery allows for innovative product development.

Hopper Volume | 20L | Material | Liner 316 material |

Size | 800*800*1700 | Weight | 160kg |

Heating power | 3KW | Electrical | 380V or 220V,customized |

Number of punches | 20 | Depositing times | 10-30times/min |

Temperature measurement areas (3 points in total) | Hopper, Bottom and Distribution Plate Temperatures | Thermometer brand | Omron |

Low voltage electrical | Siemens | Compressed air consumption | 20cbm/min |

This is high level multi-functional semi-automatic gummy candy depositing machine, which can use to deposit soft gummy candy, hard candy, lollipop candy and toffee...

It is also a small gummy candy depositor machine used to deposit syrup into different molds and shapes

Candies of different sizes and shapes can be customized according to your needs (Single color, double color, center-filing gummy candy !)

Not only can make soft candies, but also hard candies, lollipops, and even honey!!!

This is semi automatic gummy candy depositing machine ,can depositing different kind of candy shapes. Put mould into the depositing hopper by hand ,and then open the depositing button, depositing ,after syrup infused to the molds ,put out the mould ,natural cooling .

PLC touch screen control

Servo - driven pouring machine with de-moulding system

Uncompressed air

Sandwich monochrome optional

Food grade stainless steel

Constant temperature heating control system

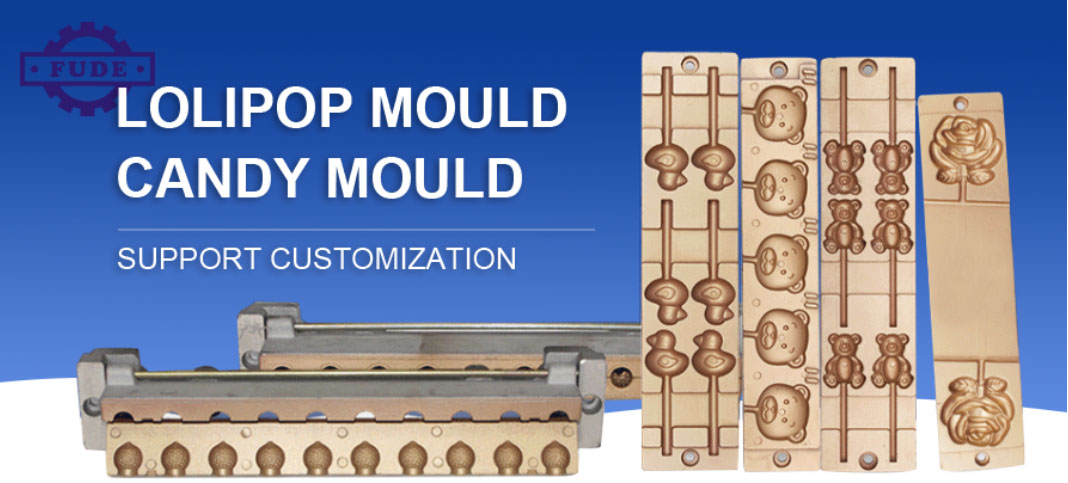

Mould:

Support 3D, silicone or metal molds, support mold customization, and produce candies of any size and shape.

Appendix:

Gummy candy is a soft, springy candy that usually comes in small pieces or shapes. They are made from ingredients such as granulated sugar, glucose syrup, and gelatin that are heated, mixed, and set. Gummies differ in taste from traditional hard candies because they are softer, chewier, and sometimes stickier.

Hard candy is a hard, chewy candy that has a firmer texture than soft candy and usually takes longer to dissolve completely. They're made from ingredients like granulated sugar, glucose syrup, or honey that are heated, mixed, and cooled.

Advantages of gummy depositing machine:

1.Increase in Speed of Production

The automatic nature of the automatic gummy depositor machine will allow you to increase the speed at which gummy candy is deposited. This will translate into an overall increase in production speed.

2.Reliable and Efficient

You can rely on the efficiency of the candy depositing machine to deposit the right quantities of gummy candy ingredients.Apart from that, the gummy candy depositing machine is reliable and will not fail during the production process.

3.Easy to Clean and Maintain

Aside from that, the automatic gummy depositor machine has a clean in place system that automatically removes debris. The maintenance cost is also quite low since spare parts are readily available.

4.High Durability Levels

Gummy depositing machines are highly durable and will serve you for a very long time if you maintain them well.It has durable materials such as stainless steel which have very high tensile strength and does not corrode easily.

5.Cost-effective

Jellies, gummies, and fruit snacks can be produced using starch-free moulding because of its small footprint, low energy costs, and lack of starch.

6.Validation for Functional & Medicated Applications

Medicated gummy machine continuous depositing systems with high output can be validated for all types of functional, medicated, and pharmaceutical confectionery.

7.Complete process

In order to bring a new product to market, Sinofude can assist at every stage. In addition to supplying the process technology for cooking and depositing, we advise on ingredients, formulations and process parameters and conduct product and process development trials in our Innovation Centres.

Your gummy production line will include this deposit jelly candy machine whether you are making ordinary jellies and gummies or functional medicated gummies.You will need the support of other equipment in the gummy-making process to have a complete production line.

Gummy Bear Equipment

Gummy Sorting Machine

Gummy Counting Machine

Gummy Packaging Machine

Additive Blender System

Oiling Drum

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.