Always striving toward excellence, SINOFUDE has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. popping boba making machine We have been investing a lot in the product R&D, which turns out to be effective that we have developed popping boba making machine. Relying on our innovative and hard-working staff, we guarantee that we offer customers the best products, the most favorable prices, and the most comprehensive services as well. Welcome to contact us if you have any questions.SINOFUDE is innovatively designed to ensure even and thorough circulation of warm wind throughout. With a built-in automatic fan, it guarantees maximum comfort without any hassle or inconvenience. Experience superior heating performance like never before. Order now!

POPPING BOBA, also known as"popping pearls" are little, pearly, spheres filled with fruit juice at about 3-30 mm in diameter.Each popping boba bursts wtih flavorful fruit juices when people bite into it. With popping boba exterior made out of Seaweed Extract & filled with fruit juice,Tea Zone Gourmet Series Popping Boba are the new craze!

Popping boba can be used to make tea, juice, ice cream, cake decoration, egg tart, frozen yogurt and so on. Popping boba is a newly developed health product,popping boba can be used in many food items. Popping boba is a unique practical type of pearl, popping boba is full of real juice flavor, burst in your mouth. Popping bobas are believed to be the latest ingredient craze in all types of drinks and yogurt.

About SINOFUDE Popping Boba Production Line

CBZ series automatic popping boba production line was developed by SINOFUDE exclusively in China in March 2010 .SINOFUDE is still the only popping boba manufacturer & factory in China so far. The unique structural design makes the popping boba produced by popping boba production line.Popping boba not only have uniform appearance、full shape、bright color and round appearance, but also have almost no deviation in weight. Popping boba are deeply loved and recognized by customers around the world!

About SINOFUDE CBZ500 popping boba Production Line

The picture shows the model CBZ500 popping boba machine, CBZ500 production line using PLC and servo control system, automatic processing design. The popping boba production line adopts PLC/ servo process control and built-in touch screen (HMI),which is easy to operate. In addition, Due to the insulation design of depositing hopper and nozzle, the popping boba production line can simultaneously produce popping boba and agar boba.

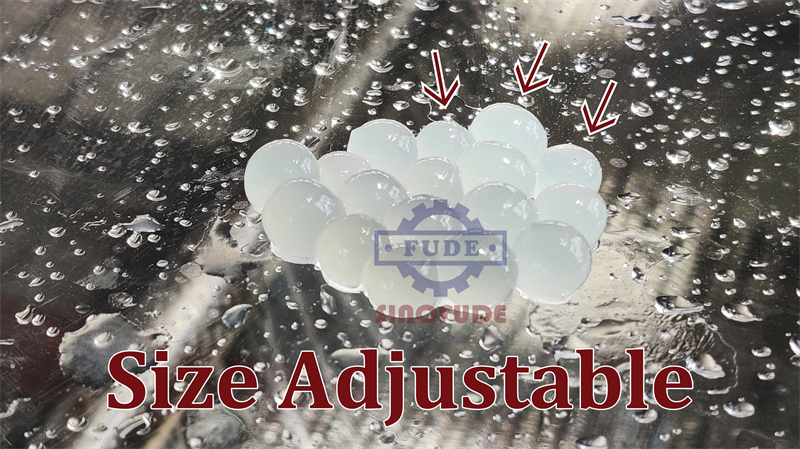

The standard popping boba production capacity range of this line is 400-500kg/h. The main parts of the popping boba production line are made of stainless steel SUS304, also can be customized SUS316. Popping boba production line is specially designed with continuous operation and material recovery device.So this device can avoid the waste of raw materials .By adjusting the depositing machine to adapt to different sizes of popping bobas.

How to make popping boba?

First, you need to have a boba making machine.In a mixing bowl, combine 1 gram of sodium alginate with 500 ml of water. Stir well until the sodium alginate is fully dissolved. Let the mixture sit for 30 minutes to remove any air bubbles.

This solution will be used to create the gelification reaction. In another mixing bowl, combine 5 grams of calcium chloride with 500 ml of water. Stir until the calcium chloride is completely dissolved.

Mix your desired fruit juice or flavored syrup with sweetener and food coloring. Adjust sweetness and flavor to your liking.

To make popping boba, add small droplets of the fruit juice or flavored syrup to the sodium alginate bath using a dropper or syringe. It is important to drop the droplets gently to prevent them from breaking. They will form small spheres as they come into contact with the sodium alginate.

Let the boba sit in the sodium alginate bath for about 3-5 minutes to allow them to form a thin skin.

With a slotted spoon or strainer, remove the boba from the sodium alginate bath. Rinse the boba gently in water to remove any excess sodium alginate.

Let the boba soak in the calcium chloride solution for another 3-5 minutes. The calcium chloride will react with the sodium alginate and create a gel-like coating.

About the raw materials for the popping boba

Three liquids :

i. Juice liquid (the liquid mainly includes water, glucose syrup, calcium lactate, calcium chloride, etc.), wrapped in the bead inside the liquid.

ii. Sodium alginate liquid, which consists of sodium alginate and water. Used to wrap juice liquids.

iii.Protective liquid, the liquid is mainly used to preserve the finished bursting bead. (The main ingredients are water, fructose, etc.)

How does Popping boba machine Work?

In short, the popping boba process involves:

i. Sodium alginate is mixed with water by a colloid mill.

ii. Cooking the core and leather materials at the same time.

iii. The core and leather materials are transferred to the cooling tank through the conveying pump.

iv. The cooled core and leather materials are transported to the depositing machine by the conveying pump.

v. After depositing , forming.

vi. Filtration.

vii. Cleaning.

What are the machine of the Popping boba Production Line?

An popping boba making machine has different parts that all work together to accomplish the popping boba process.

1. Colloid mill

Since sodium alginate is slightly soluble in water, it is insoluble in most solvents. It dissolves in alkaline solutions, making them sticky. The sodium alginate powder becomes wet when it encounters water, and the hydration of the particles makes its surface sticky. The particles then quickly bond together to form clumps, which slowly hydrate and dissolve. Therefore, the equipment is needed to assist the sodium alginate to dissolve in water and improve the dissolution rate.

2. Cooking system

i.Storage and continuous operation.

ii. Independent PLC control system.

iii.Automatic weighing system available(if you need ).

iv. Double heat preservation system.

v. High shearing inside.

vi. Longer using life.

2-1. Vertical sandwich pot (with stirring)

The equipment is mainly used for boiling jam liquid and coagulating liquid raw materials, using scraping type stirring. Available steam heating, electric heating.

2-2. Cooling tank

The equipment is mainly used to reduce the temperature of raw materials after boiling, and temporary storage function.

2-3 conveying pump

Mainly used for conveying liquid raw materials. The pump body is made of 304 stainless steel.

3. Molding system:

i.CNC processing, more accurate touch screen more easy operation.

ii. Reasonable wastewater discharge system.

iii.All electric components have mark to track.

iv. Quick release buckle.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.