Relying on advanced technology, excellent production capabilities, and perfect service, SINOFUDE takes the lead in the industry now and spreads our SINOFUDE all over the world. Together with our products, our services are also supplied to be the highest-level. biscuit maker machine SINOFUDE have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - high-quality biscuit maker machine for business, or would like to partner up, we'd love to hear from you.Our biscuit maker machine adopts an intelligent control system with high control precision, and can set temperature, humidity, speed and other parameters according to their own needs, saving worry and time.

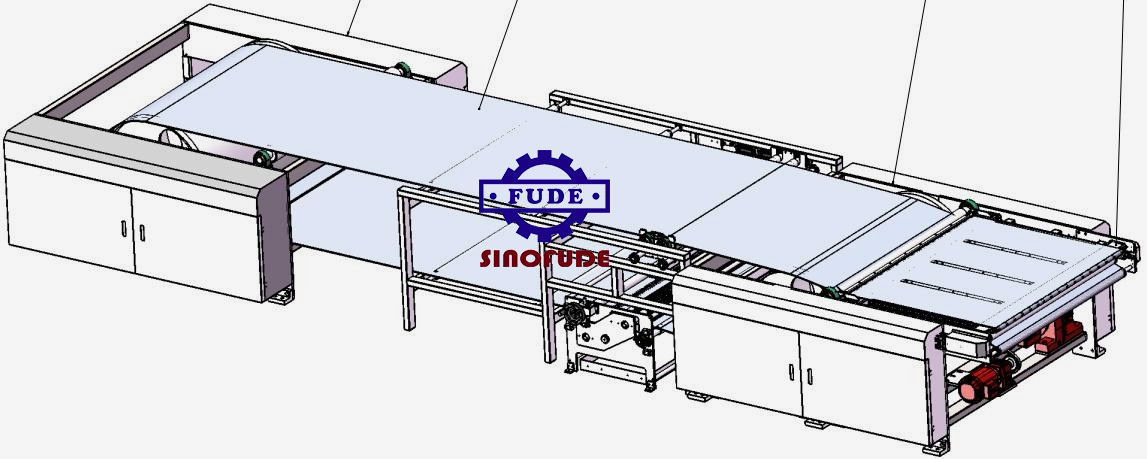

Biscuit can be grouped into hard biscuit、soft biscuit、 cookie biscuit, according to the formula, process, and different forming method.Automatic biscuit production line is generally composed of a feeding machine (if producing the soda biscuit or chocolate coated biscuit, another lamination process is needed a set of dough roller, through the dough rolling and dough sheeting, then through the roller cutting machine, rest material recycling device, inlet oven machine, the entire biscuit forming line. -or soft biscuit and cookie biscuit production line.only the forming machine and inlet oven machine can be the whole forming process. In order to increase the biscuit types and characteristics. customers can allocate the sugar & salt sprinkling machine, egg spraying machine, calico printing machine, etc. The oven is to make the formed biscuit into delicious food. You can choose different types of bakery oven (electric/gas diesel/thermal oil for baking different types of products. Dough rolling width ranges from 250mm to 1500mm(you have special needs, we can customized for you, we are one of the most professional biscuit production line manufacturers in China with over 30 years of experiences).

BCQ-250 | BCM250 | BCM480 | BCM600 | BCQ800 | BCQ1000 | BCQ1200 | BCQ1500 |

Production capacity (kg/h ) | 250 | 480 | 600 | 750 | 1000 | 1250 | 1500 |

Total length (mm) | 29600 | 64500 | 85500 | 92500 | 125000 | 125000 | 150000 |

Whole line power (kw) | 105 | 190 | 300 | 400 | 500 | 600 | 750 |

Whole line weight (kg) | 6000 | 12000 | 20000 | 28000 | 35000 | 45000 | 55000 |

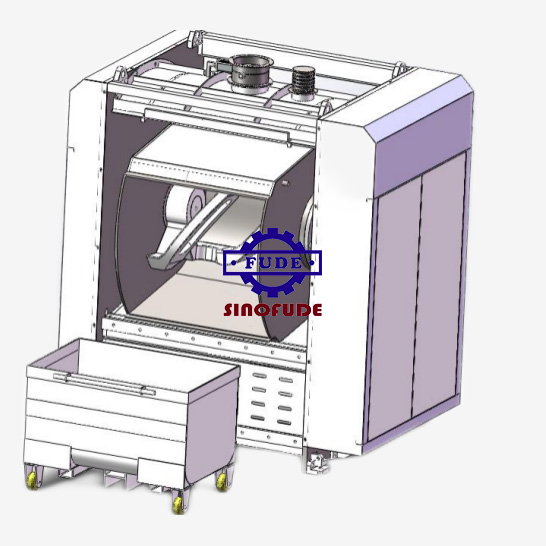

Horizontal dough mixer

The horizontal noodle kneading machine is a fully automatic noodle processing equipment. The main function of the horizontal noodle kneading machine is to mix flour and water evenly, instead of manual noodle kneading, reduce labor intensity, and meet people's food hygiene requirements. The horizontal dough kneading machine adopts manual tipping bucket, open gear transmission, high efficiency, strong adaptability, compact structure, good sealing, uniform kneading, convenient inversion, simple operation, low power consumption, low noise, etc. The biscuit manufacturing equipment is widely used in western food restaurants, cake shops, casual fast food restaurants, bakeries, restaurants and other food units.

Specification Type | Quantity of mixing | Time of Mixing | Power supply | Power of main motor | Measurement L×W×H |

CHWJ25 | 25kg | 10-25 | 1.5kw | - | 880×460×886 |

CHWJ50 | 50kg | 10-25 | 3kw | 0.37kw | 1110×630×1070 |

CHWJ75 | 75kg | 10-25 | 4kw | 0.37kw | 1188×710×1220 |

CHWJ100 | 100kg | 10-25 | 5.5kw | 0.37kw | 1250×740×1300 |

CHWJ125 | 125kg | 10-25 | 7.5kw | 0.37kw | 1540×800×1375 |

CHWJ150 | 150kg | 10-25 | 9.5kw | 0.37kw | 1400×900×1450 |

CHWJ250 | 250kg | 10-25 | 11kw | 0.55kw | 1600×1000×1650 |

CHWJ500 | 500kg | 10-25 | 45kw | 2.2kw | 2960×1650×2632 |

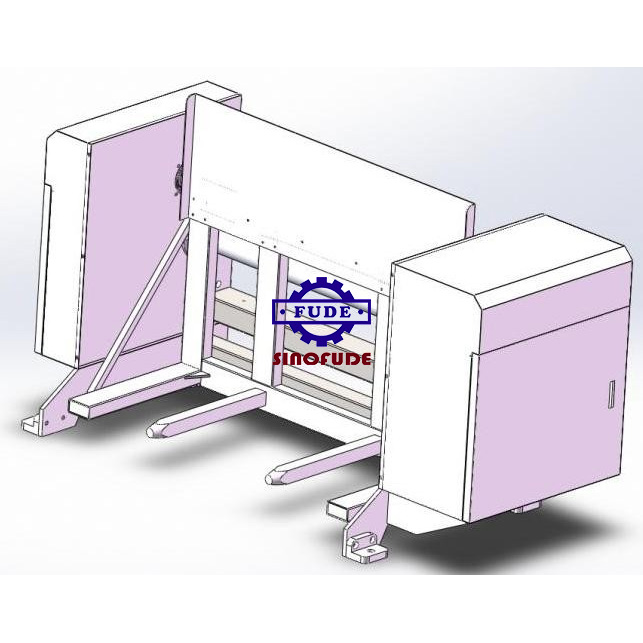

Vertical dough mixer

The soft dough biscuit production line equipment of the vertical noodle machine is mainly, its main function is wheat flour and food oil, food sugar and its food and auxiliary materials, etc. Pasta and other foods.

Pouring machine

Each batch of dough is conveyed to the dumping machine through the transfer bucket.

The dough in the barrel is poured into the *U*-shaped dough placing table through the switch control.

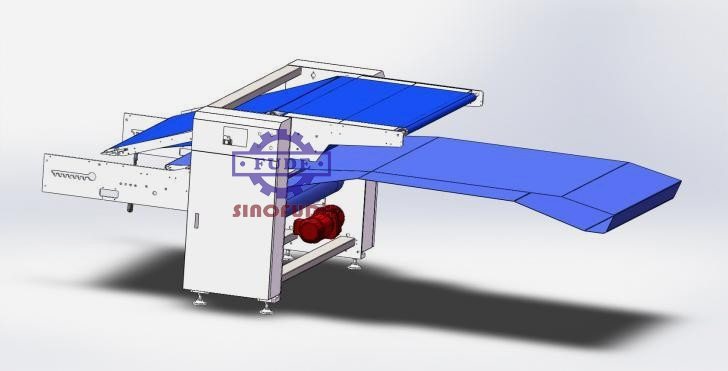

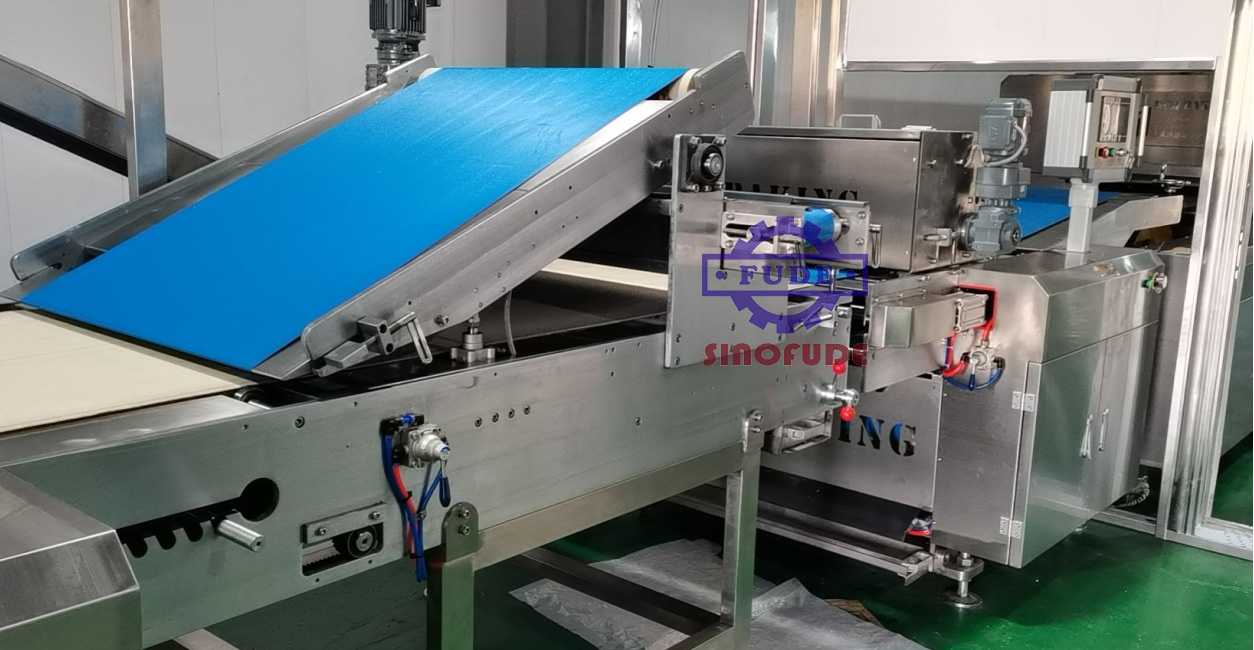

Automatic feeder and cutting system

The mixed dough is conveyed to the forming machine through the dough conveying system. It is pressed by rollers, and then formed by a roller cutting mold. The stroke biscuit is green and baked to make a tough biscuit.

Specification | Capacity/hour | Power | Weight | Measurement L×W×H |

250 | 100kg | 1.5kw | 1000kg | 4500×750×1400 |

400 | 250kg | 4.1kw | 2000kg | 5000×820×1600 |

600 | 500kg | 5.5kw | 2600kg | 6500×920×1750 |

800 | 750kg | 12kw | 3000kg | 7000×1020×1750 |

1000 | 1000kg | 18kw | 3500kg | 7000×1220×1750 |

1200 | 1250kg | 20kw | 4000kg | 7000×1420×1750 |

1500 | 1500kg | 28kw | 5000kg | 7000×1520×1750 |

Dough separating unit

The separator separates the roll-cut dough from the roll-cut biscuit embryo, keeps the separated biscuit embryo intact, and recovers the remaining material to continue pressing the skin to make biscuits. The part of the separation slope can be adjusted back and forth horizontally, and the separation position can be adjusted according to the quality of the dough to achieve the separation effect. Equipped with horizontal recycling, the leftover material is sent to the side recycling machine or the front recycling machine, and the horizontal recycling can operate in both directions, which is convenient for processing and recycling the leftover material.

Dough recycling machine

After biscuits forming, the rest dough will be back to the Lamination machine, also used for feeding of biscuit dough.

Rotary Moulder

Rotary Moulder is used for forming soft biscuit, which contains much oil and fat. The dough would form as the shape of biscuit and drop on the conveyor belt to the next machine.The gap between material enter roller and mold can be adjusted by hand wheel The pressure of rubber roller also can be adjusted by hand wheel The scrapper can be adjusted up and down by hand wheel The angle of scrapper can be adjusted by hand wheel .Material hopper can be free to flip and can be combined freely Conveyor belt is easy to change,power roller easy to disassemble Cover,supporting plate is stainless steel Pneumatic rectify deviation .

Specification Type | Weight | Power | Weight | Measurement mm L×W×H |

250 | 100kg | 2.2kw | 500kg | 2450×550×1400 |

400 | 250kg | 3kw | 750kg | 2450×700×1400 |

600 | 500kg | 3kw | 900kg | 2450×900×1400 |

800 | 750kg | 4kw | 1200kg | 2450×1100×1400 |

1000 | 1000kg | 4kw | 1450kg | 2450×1300×1400 |

1200 | 1250kg | 4kw | 1600kg | 2450×1500×1400 |

1500 | 1500kg | 5kw | 1600kg | 2450×1500×1400 |

Salt/Sugar Sprinkler

Spray sugar or salt particle on the surface of biscuits to make the biscuits taste better. The extra sugar and salt particle will be on the tray, can be reuse.

Specification Type | Power | Weight | Measurement mm L×W×H |

250 | 1.5kw | 600kg | 800×450×1550 |

400 | 3kw | 700kg | 800×650×1550 |

600 | 4kw | 820kg | 800×850×1550 |

800 | 4kw | 950kg | 800×1050×1550 |

1000 | 4kw | 1050kg | 800×1250×1550 |

1200 | 4kw | 1200kg | 800×1450×1550 |

1500 | 4kw | 1350kg | 800×1850×1550 |

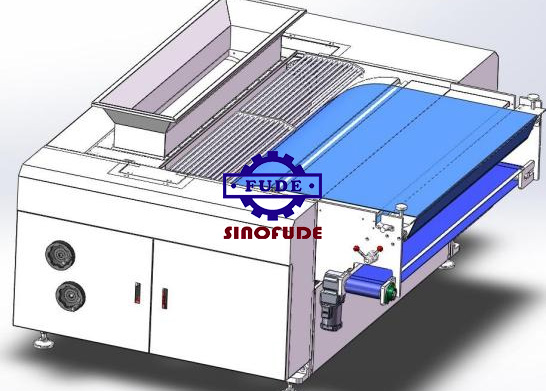

Inlet conveyor

Function: Transits the biscuit on to wire mesh of baking machine.The oven machine is the molding of biscuits or other baked products into the oven transmission device, by the big roller connected to the wire mesh belt biscuits continuous into the oven for baking.

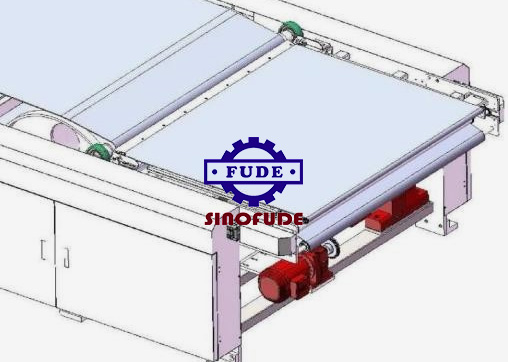

Belt driven and tension unit

The equipment is provided with a power outage manual discharging mode.Carrying coal-scuttle to transmit and regulate finished products.

Specification Type | Power | Weight | Measurement mm L×W×H |

250 | 2.2kw | 250kg | 1800×550×1300 |

400 | 3kw | 400kg | 1800×700×1300 |

600 | 3kw | 550kg | 1800×900×1300 |

800 | 4kw | 700kg | 1800×1100×1300 |

1000 | 4kw | 850kg | 1800×1300×1300 |

1200 | 5.5kw | 1000kg | 1800×1500×1300 |

1500 | 5.5kw | 1100kg | 1800×2430×1300 |

Electric Heating Oven

Electric heating oven is so called far infrared heating oven, mainly depends on electrical heated pipe. Main features including: clean and sanitary, accurate controlled temperature, easy to operate, easily maintain and wide range of application.

Gas/Diesel Fire Heating Oven

Fuels of natural gas, liquefied gas electic and diesel can be chosed as baking energy. Those can be light up immediately, but for diesel based hot air circulation oven is necessary. Main features including: large capacity, fast production speed, high quality, accurate controlled and neat.

Technical parameters

Specification Type | Capacity | Oven length | Temperature Zones | Natural gas consumption | Diesel | Power |

600 | 600kg | 50m | 4 | 12-20kg/h | 20-45kg/h | 300kw/h |

800 | 800kg | 60m | 4 | 15-25kg/h | 30-55kg/h | 400kw/h |

1000 | 1000kg | 60m | 4 | 20-35kg/h | 30-60kg/h | 500kw/h |

1200 | 1200kg | 60m | 4 | 25-40kg/h | 40-70kg/h | 600kw/h |

1500 | 1500kg | 70m | 5 | 30-50kg/h | 50-80kg/h | 7500kw/h |

Outlet conveyor

Conveying the biscuits from the oven to the oil sprayer ensures a longer shelf life and a better flavor for the biscuits. The machine works smoothly, with low noise, convenient operation and large conveying capacity.

Oil- Spraying Machine

Function: the hot biscuits which are just out of the oven are immediately put into the oil-spraying process, which is necessary for production of high-grade biscuit, to better improve grades and colors of biscuit.

Specification Type | Power | Weight | Measurement mm L×W×H |

250 | 5kw | 260kg | 1650×500×1550 |

400 | 7kw | 400kg | 1650×650×1550 |

600 | 9kw | 560kg | 1650×850×1550 |

800 | 12.5kw | 700kg | 1650×1050×1550 |

1000 | 12.5kw | 900kg | 1650×1250×1550 |

1200 | 15kw | 1100kg | 1650×1450×1550 |

1500 | 18kw | 1500kg | 1650×1860×1550 |

Swerve Conveyor(L Or U Turn)

Function: The swerve conveyor is optional equipment in automatic biscuit production line. When the space (workshop) is not long enough to place the production line straight, then L swerve or U turn conveyor need to be adopted.

Technical parameters

Specification Type | Power | Weight | Measurement mm L×W×H |

400 | 2.2kw | 320kg | 3500×1700×800 |

600 | 3kw | 420kg | 4200×2100×800 |

800 | 5kw | 490kg | 4800×2400×800 |

1000 | 5kw | 580kg | 5200×2600×800 |

1200 | 5kw | 660kg | 6000×3000×800 |

1500 | 5kw | 769kg | 7200×4200×800 |

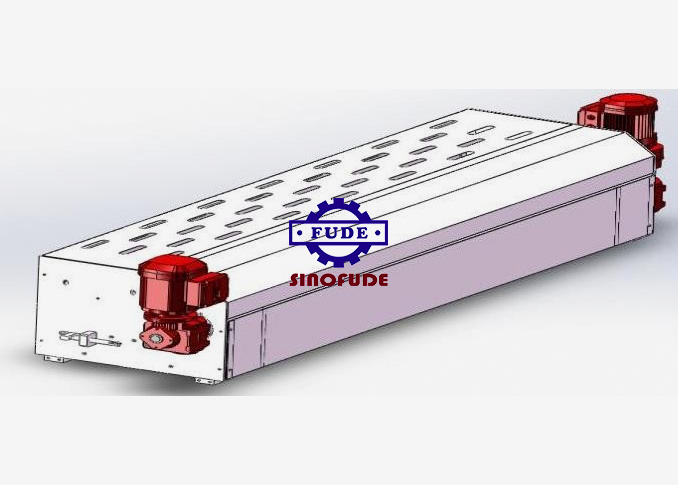

Cooling conveyor

This conveyor is used for cooling down the biscuits after baking to enable the products complete cool down for arranging and packaging. The design of this cooling conveyor may be varied subject to the different requirements and site environment.

The layout could be straight line, three-layer ”z” shape or suspension type structure The cooling conveyor is used for normal cooling. Made of stainless steel square pipes of proper strength, the cooling conveyor is structurally simple and compact. The whole machine looks light and stable, and is easy to install and remove.

Conveyor belt: PU belt, automatic deviation adjustment, pneumatic tension can also refer to packing table.

Stacking machine

This machine is a new generation of equipment that stands up and closely arranges the cooled biscuits into a number of neat rows, which can effectively improve the efficiency of biscuit packaging. Using advanced frequency converter for stepless speed regulation, stable speed, high efficiency and energy saving; It is equipped with magnetic separator, which can adjust the width quickly. It has special structure design, suitable for ultra-thin and other cookies of different dimensions.

Specification Type | Capacity | Power | Weight | Measurement mm L×W×H |

400 | 250kg | 2.2kw | 360kg | 2980×800×1350 |

600 | 500kg | 4kw | 480kg | 2980×900×1350 |

800 | 750kg | 4kw | 600kg | 2980×1200×1350 |

1000 | 1000kg | 5.5kw | 720kg | 2980×1300×1350 |

1200 | 1250kg | 5.5kw | 840kg | 2980×1500×1350 |

1500 | 1500kg | 6.5kw | 960kg | 3400×2160×1180 |

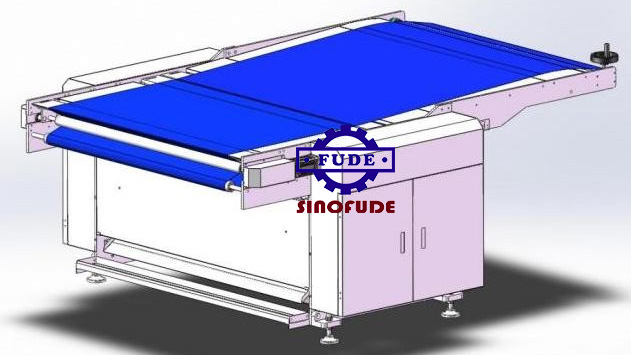

Packing table

It is used for checking the quality of biscuits before packaging. Equipped with an anti-biscuit-reversing device.

Conveyor belt Air cylinder tension, gear synchronization action at both sides and left and right, auto deflflection,each conveyor belt has installed auto deflflection at front and behind.With the diamond shape supporting arm, the supporting frame has little dust accumulation, and is easy to clean.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.