Introduction:Automatic Multifunctional Biscuit Production Line

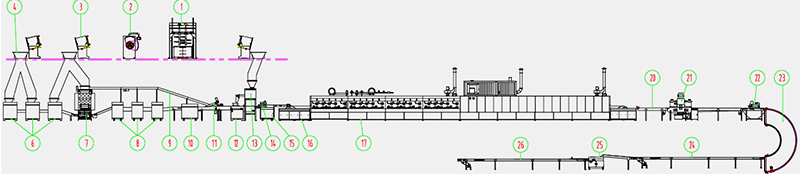

1. Multifunctional biscuit production line

Can produce various types of crisp biscuits, tough biscuits, three-color (sandwich) biscuits, etc.

Machine configuration:

1. Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 4 falling hopper → 5 dough conveyor → 6 feeding machine → 7 laminator → 8 rolling machine → 9 remaining material recovery machine → 10 Roll cutting machine → 11 separator → 12 roll printing machine → 13 crisp powder blanking machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 17 mixed oven (direct-fired oven + hot air Convection circulation oven) → 20 out of the oven → 21 fuel injection machine → 22 vibration spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

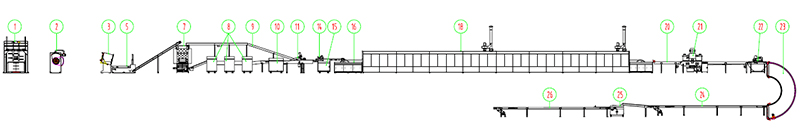

2. Automatic Hard biscuit production line

Can produce various types of hard biscuits such as cracker, soda biscuit, etc.

Machine configuration:

1. Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 5 dough conveyor → 7 laminator → 8 rolling machine → 9 residual material recovery machine → 10 rolling cutter → 11 separator → 14 Spreader → 15 furnace machine → 16 mesh belt drive machine → 18 electric oven → 20 furnace machine → 21 fuel injection machine → 22 vibrating feeder → 23 turning machine → 24 cooling conveyor → 25 star wheel Cake machine → 26 cake picking conveyor

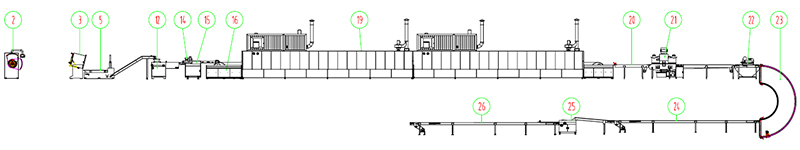

3. Automatic soft biscuit production line

Can produce various types of soft biscuits, like Marie Biscuit, Glucose Biscuit etc.

Machine configuration:

2 horizontal dough mixer → 3 dumper → 5 dough conveyor → 12 roll printing machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 18 hot air convection circulating oven → 20 discharge machine → 21 Fuel injection machine → 22 vibrating spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

Always striving toward excellence, SINOFUDE has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. biscuit production line Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product biscuit production line or our company, feel free to contact us.Our biscuit production line adopts an intelligent control system with high control precision, and can set temperature, humidity, speed and other parameters according to their own needs, saving worry and time.

1. Multifunctional biscuit production line

Can produce various types of crisp biscuits, tough biscuits, three-color (sandwich) biscuits, etc.

Machine configuration:

Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 4 falling hopper → 5 dough conveyor → 6 feeding machine → 7 laminator → 8 rolling machine → 9 remaining material recovery machine → 10 Roll cutting machine → 11 separator → 12 roll printing machine → 13 crisp powder blanking machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 17 mixed oven (direct-fired oven + hot air Convection circulation oven) → 20 out of the oven → 21 fuel injection machine → 22 vibration spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

2. Automatic Hard biscuit production line

Can produce various types of hard biscuits such as cracker, soda biscuit, etc.

Machine configuration:

Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 5 dough conveyor → 7 laminator → 8 rolling machine → 9 residual material recovery machine → 10 rolling cutter → 11 separator → 14 Spreader → 15 furnace machine → 16 mesh belt drive machine → 18 electric oven → 20 furnace machine → 21 fuel injection machine → 22 vibrating feeder → 23 turning machine → 24 cooling conveyor → 25 star wheel Cake machine → 26 cake picking conveyor

3. Automatic soft biscuit production line

Can produce various types of soft biscuits, like Marie Biscuit, Glucose Biscuit etc..

Machine configuration:

2 horizontal dough mixer → 3 dumper → 5 dough conveyor → 12 roll printing machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 18 hot air convection circulating oven → 20 discharge machine → 21 Fuel injection machine → 22 vibrating spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

Model | BBG250 | BBG400 | BBG600 | BBG800 | BBG1000 | BBG1200 | BBG1500 |

Capacity | 50-80kg/H | 100-200kg/H | 200-400kg/H | 400-600kg/H | 600-1000kg/H | 1000-1500kg/H | 1500-2000kg/H |

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.