Introduction:Automatic Multifunctional Biscuit Production Line

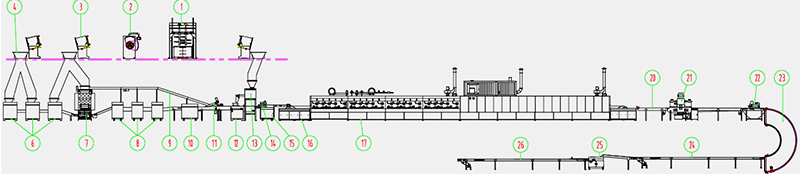

1. Multifunctional biscuit production line

Can produce various types of crisp biscuits, tough biscuits, three-color (sandwich) biscuits, etc.

Machine configuration:

1. Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 4 falling hopper → 5 dough conveyor → 6 feeding machine → 7 laminator → 8 rolling machine → 9 remaining material recovery machine → 10 Roll cutting machine → 11 separator → 12 roll printing machine → 13 crisp powder blanking machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 17 mixed oven (direct-fired oven + hot air Convection circulation oven) → 20 out of the oven → 21 fuel injection machine → 22 vibration spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

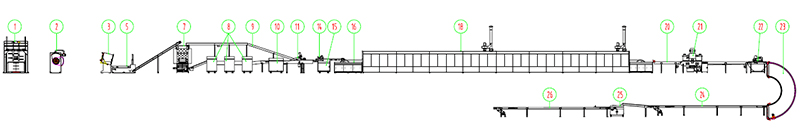

2. Automatic Hard biscuit production line

Can produce various types of hard biscuits such as cracker, soda biscuit, etc.

Machine configuration:

1. Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 5 dough conveyor → 7 laminator → 8 rolling machine → 9 residual material recovery machine → 10 rolling cutter → 11 separator → 14 Spreader → 15 furnace machine → 16 mesh belt drive machine → 18 electric oven → 20 furnace machine → 21 fuel injection machine → 22 vibrating feeder → 23 turning machine → 24 cooling conveyor → 25 star wheel Cake machine → 26 cake picking conveyor

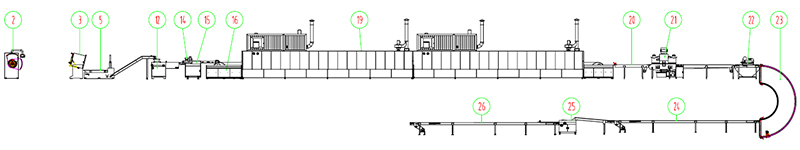

3. Automatic soft biscuit production line

Can produce various types of soft biscuits, like Marie Biscuit, Glucose Biscuit etc.

Machine configuration:

2 horizontal dough mixer → 3 dumper → 5 dough conveyor → 12 roll printing machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 18 hot air convection circulating oven → 20 discharge machine → 21 Fuel injection machine → 22 vibrating spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

Guided by scientific and technological innovation, SINOFUDE always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. soft biscuit production line We have been investing a lot in the product R&D, which turns out to be effective that we have developed soft biscuit production line. Relying on our innovative and hard-working staff, we guarantee that we offer customers the best products, the most favorable prices, and the most comprehensive services as well. Welcome to contact us if you have any questions.If you are looking for a blend of aesthetic appeal and durability in your door panels, stainless steel is the way to go (soft biscuit production line). Both the interior and exterior of our doors feature stainless steel panels that are crafted to perfection and add a touch of finesse to any setting. The panels are robust and long-lasting, with rust not being a concern even after prolonged use. Furthermore, maintaining and cleaning them is a breeze. Discover the perfect blend of form and function with our stainless steel door panels.

1. Multifunctional biscuit production line

Can produce various types of crisp biscuits, tough biscuits, three-color (sandwich) biscuits, etc.

Machine configuration:

Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 4 falling hopper → 5 dough conveyor → 6 feeding machine → 7 laminator → 8 rolling machine → 9 remaining material recovery machine → 10 Roll cutting machine → 11 separator → 12 roll printing machine → 13 crisp powder blanking machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 17 mixed oven (direct-fired oven + hot air Convection circulation oven) → 20 out of the oven → 21 fuel injection machine → 22 vibration spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

2. Automatic Hard biscuit production line

Can produce various types of hard biscuits such as cracker, soda biscuit, etc.

Machine configuration:

Vertical kneading machine → 2 horizontal kneading machine → 3 dumping machine → 5 dough conveyor → 7 laminator → 8 rolling machine → 9 residual material recovery machine → 10 rolling cutter → 11 separator → 14 Spreader → 15 furnace machine → 16 mesh belt drive machine → 18 electric oven → 20 furnace machine → 21 fuel injection machine → 22 vibrating feeder → 23 turning machine → 24 cooling conveyor → 25 star wheel Cake machine → 26 cake picking conveyor

3. Automatic soft biscuit production line

Can produce various types of soft biscuits, like Marie Biscuit, Glucose Biscuit etc..

Machine configuration:

2 horizontal dough mixer → 3 dumper → 5 dough conveyor → 12 roll printing machine → 14 spreader → 15 furnace machine → 16 mesh belt drive machine → 18 hot air convection circulating oven → 20 discharge machine → 21 Fuel injection machine → 22 vibrating spreader → 23 turning machine → 24 cooling conveyor → 25 star wheel cake sorting machine → 26 cake picking conveyor

Model | BBG250 | BBG400 | BBG600 | BBG800 | BBG1000 | BBG1200 | BBG1500 |

Capacity | 50-80kg/H | 100-200kg/H | 200-400kg/H | 400-600kg/H | 600-1000kg/H | 1000-1500kg/H | 1500-2000kg/H |

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.