Our SINOFUDE gummy manufacturing machine is manufactured in strict compliance with the food industry standards. We ensure that each part is meticulously disinfected before integration into the primary structure. Trust us to deliver the best quality product.

Set up years ago, SINOFUDE is a professional manufacturer and also a supplier with strong capabilities in production, design, and R&D. gummy manufacturing machine Today, SINOFUDE ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product gummy manufacturing machine and our company by directly contacting us.gummy manufacturing machine Our system is intelligently designed for precise control and customization of temperature, humidity, and speed parameters, providing users with convenient time-saving options. With our advanced control system, users can easily set and adjust parameters to their desired settings for optimal performance. Say goodbye to worries and hello to efficient operations.

What is a gummy making machine? CLM150 gummy bear making machine

CLM150 gummy bear making machine was specially innovated by our R&D department according to the candies market, which can produce gummy with multiple shapes and variety colors on base of advanced technology process. lt is an ideal machine to produce superior quality gummy candy of single color and double color; By change-over molds or depositors, different color and different shape of gummy can be also produced. The on-line mixer achieves the quantitative dosing and mixing of the flavor, color and acid.High degree of automation can produce super quality of gummy, at the same time it saves the manpower and the space

The manufacture of gummy bear machinery equipment requires specialized machinery and tools, designed to achieve effectiveness and precision. These components include mixers which are integral to combining ingredients such as gelatin, sugar syrup, colors, and flavors until an even mixture is formed. This concoction is then directed towards depositor nozzles that accurately portion the candy mass into molds or starch trays in predetermined shapes and amounts. As the molds make their way through cooling tunnels, cooling systems harden the candy's shape. After demolding using either automated stripping machines or manual techniques as needed; packaging machines complete the wrapping or sealing prior to distribution. Thanks to features like refined mechanisms and advanced technology implemented in this equipment's processes, manufacturers can produce delicious gummy bears with scrumptious textures and lively hues that captivate consumers worldwide.

Automatic Gummy Production Line by change different molds to make many kinds of shapes gummies. It has 15" touch screent make your operate fully automatically.

Single color

CLM150 gummy bear making machine

48,000-60,000pcs gummy candy per hour 150kg/h

Gummy are versatile treats that offer more than just sweetness. In addition to being delicious confectionery, they can also be enhanced with active ingredients to promote a healthy lifestyle. These may include immune-boosting vitamins, bone-strengthening calcium, sleep-inducing melatonin, and supplements for hair and skin health such as collagen. Natural extracts from fruits like elderberry and cranberry or plants like turmeric and valerian can also be incorporated into gummy and jellies for added nutritional benefits. With Sinofude Machinery as your reliable manufacturer of gummy bear making machine, you can trust in the precision and expertise it provides to help you create the perfect gummy with both ideal taste and accurate nutritional value.

Whether you specialize in traditional confectionery Gummy or health-boosting fortified Gummy, having the right manufacturing equipment is essential for creating a standout product. Our team of specialists collaborates with you to create custom fondant manufacturing equipment tailored to your specific needs and preferences. Want to offer unique Gummy flavors or innovative shapes and sizes? Let us help you tackle the task of producing the necessary Gummy manufacturing equipment.Sinofude Machinery offers you Gummy production equipment and gummy bear manufacturing equipment. Contact us today to learn how our equipment can help you succeed!

Benefits of gummy bear manufacturing equipment

Gummy bear manufacturing equipment, with its advanced technological capabilities, offers numerous benefits for confectionery companies seeking to optimize their production processes and create high-quality gummy bear products. This specialized machinery enables efficient mass production of gummy bears, reducing labor costs and increasing overall productivity. The precise dosing mechanisms ensure accurate ingredient measurements, resulting in consistent flavor profiles and textures that delight consumers' taste buds. Additionally, the sophisticated shaping molds allow for a wide range of creative designs and customization options, appealing to diverse consumer preferences. These machines are also designed with hygiene and safety in mind; they incorporate easy-to-clean surfaces and automated cleaning cycles to maintain strict food industry standards. Furthermore, gummy bear manufacturing equipment often incorporates user-friendly interfaces equipped with programmable controls that enable operators to easily adjust settings according to specific recipes or product variations. With reduced manual intervention required throughout the manufacturing process, companies can achieve remarkable efficiency gains while maintaining top-notch quality standards—a win-win situation that positively impacts their bottom line while delivering delightful experiences to gummy bear enthusiasts worldwide.

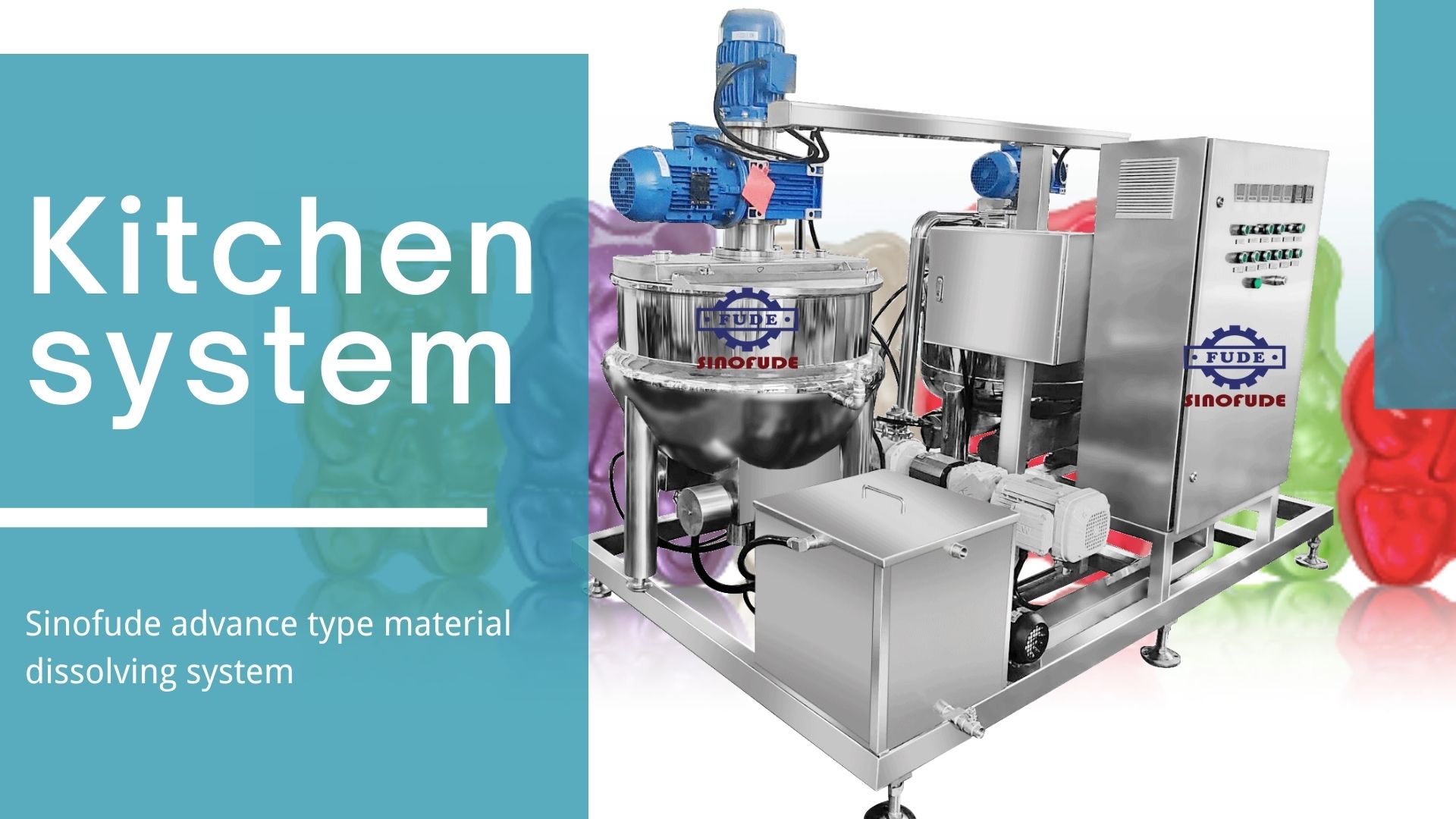

Kitchen system

Different raw materials of gummy bear equipment can be put into the jacketed kettle according to the formula, and after being processed by our stirring and heating device, the syrup is prepared for you.

1. All cookers are waterproof

2. Set all cookers and tank on frame.

3. 3.Three-layers Jacket Cooker for protection

Depositing and cooling system

Accuracy depositor

EFFICIENT HYGIENIC COOLING TUNNEL

0-20 Centigrade 15HP tunnel utilizes a Food Grade, Anti Stick FDA approved Polyurethane cooling belt and provides a panel

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.