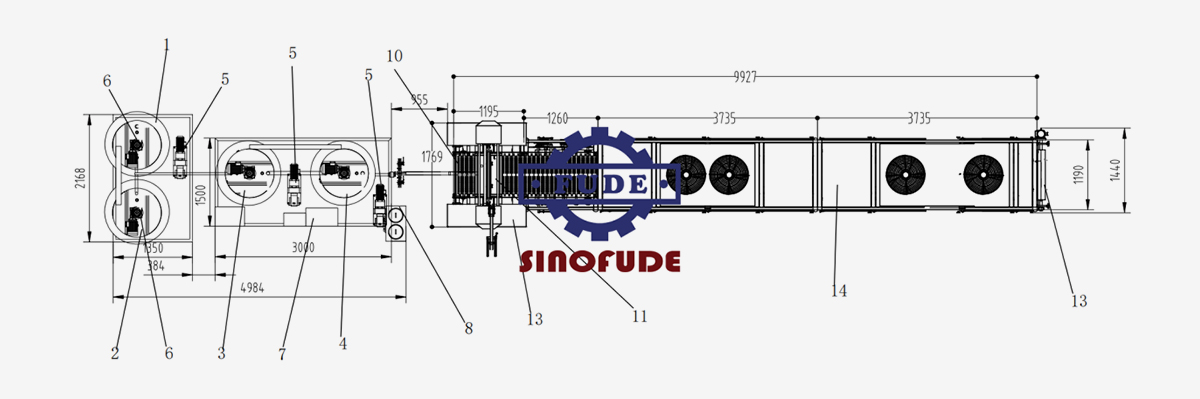

CLM300 tag nrho tsis siv neeg gummy khoom qab zib ntau lawm kab, uas tshwj xeeb tshaj yog tsim rau ua cov khoom qab zib haumxeeb thiab CBD / THC mos khoom qab zib. Nws yog ib txoj kab ntau lawm thiab txuag chaw. Nyob rau tib lub sijhawm, nws tau txais ntau daim ntawv pov thawj thiab ntawv pov thawj, xws li CE thiab UL daim ntawv pov thawj. Tag nrho cov kab ntau lawm tau muab faib ua 4 qhov hauv tag nrho: 1.cooking system 2.CFA mixing system 3.depositing system 4.cooling system. Tsis muaj teeb meem dab tsi ntawm gummy khoom qab zib koj xav ua, peb cov cav tov tuaj yeem ua rau nws tshwm sim. Peb kuj zoo siab tos txais koj qhov kev sab laj kev sib tham.

CLM300 tag nrho tsis siv neeg gummy khoom qab zib ntau lawm kab, uas tshwj xeeb tshaj yog tsim rau ua cov khoom qab zib haumxeeb thiab CBD / THC mos khoom qab zib. Nws yog ib txoj kab ntau lawm thiab txuag chaw. Nyob rau tib lub sijhawm, nws tau txais ntau daim ntawv pov thawj thiab ntawv pov thawj, xws li CE thiab UL daim ntawv pov thawj. Tag nrho cov kab ntau lawm tau muab faib ua 4 qhov hauv tag nrho: 1.cooking system 2.CFA mixing system 3.depositing system 4.cooling system. Tsis muaj teeb meem dab tsi ntawm gummy khoom qab zib koj xav ua, peb cov cav tov tuaj yeem ua rau nws tshwm sim. Peb kuj zoo siab tos txais koj qhov kev sab laj kev sib tham.

Qauv | CLM300-A |

Muaj peev xwm | 300 |

Kev tso nyiaj mob stroke (Pcs) | 40 |

Pcs ntawm pwm | 260 Ntev hom |

Cia txiashauv Capacity | 16 hp cas |

Hluav taws xob xav tau | 30-60 kWm |

Compressed cua noj | 0.80m3 / min |

Qhov hnyav tag nrho (Kgs) | Kwv yees li 6000 |

1. Cov xwm txheej xav tau rau kev tsim cov txheej txheem: Chav tsev kub 20 ~ 25 ℃, av noo< 55% | |

Layout/PID:

Lub ntsiab nta:

1. Tag nrho Stainless hlau SUS304 ncej, npog, thiab lwm yam SUS316 zaub mov tiv tauj ib feem.

2. Txhua txoj kev ua ntej machining zoo li CNC, laser txiav thiab vuam, hlau

txiav thiab lwm yam rau cov khoom siv tshuab ua kom lav qhov kev ua tau zoo ntawm tag nrho cov kab.

3. Ob hom sib txawv ntawm CFA system tuaj yeem siv rau tsis siv neeg ntxiv xim& tsw, los yog ntxiv kua qaub vitamin / THC CBD thiab lwm yam hwj chim los yog kua khoom xyaw.

4. Kev xaiv rau qhov hnyav thiab batching sib xyaw ntawm tag nrho cov khoom xyaw, suav nrog CFA, cov khoom xyaw nquag thiab lwm yam.

5. Cov thev naus laus zis tshiab tshaj plaws rau kev ua haujlwm txhua qhov kev tswj hwm thiab ua haujlwm muaj nyob hauv PLC thiab kov npo.

6.Servo system muaj tseeb dua rau kev tso nyiaj tswj tau zoo thiab hloov ntau yam sib txawv rau ob xim lossis ntim.

7.2D lossis 3D gummy muaj nyob nrog kev hloov cov khoom qab zib pwm.

8. Kev ua haujlwm siab ua haujlwm tuaj yeem tau txais txiaj ntsig ntau dua thiab txuag cov neeg ua haujlwm, ua kom lub neej ntev ntawm lub tshuab.

Cov npe khoom siv:

KEV SIB THAM:

Muaj xws li:

1. 3-Layers Fixed Cooker nrog Scrapper Stirrer

2. Kev kub ceev shearing tshuab nrog VFD tswj

3. Lobe Pump rau hloov cov kua txiv hmab txiv ntoo siav

4. Kev ua kom sov (dej tank, cua sov cov ntsiab lus, twj tso kua mis, ntsuas kub, kav dej thiab lwm yam)

5. 3-txheej Txias Tank nrog Scrapper Stirrer

6. 3-txheej Cia Tank nrog Scrapper Stirrer

7. Hluav taws xob tswj txee thiab Skid ncej

Qhov zoo ntawm SINOFUDE cookers:

1. Teflon scraping thiab nplawm kom ntseeg tau tias cov zaub mov muaj kev nyab xeeb

2. 3 txheej ntawm rwb thaiv tsev, zoo rwb thaiv tsev nyhuv, thiab tiv thaiv cov neeg ua hauj lwm kev nyab xeeb

3. Kev kub ceev shearing tso cai rau lub melting zoo meej ntawm macromolecular raw khoom

4. Yuav txuas nrog CIP tu system, kev tu tshuab yog yooj yim dua

Qee cov ntsiab lus:

Lobe Hloov Pump

Hom foob: mechanical seal seal Configuration: pa mechanical seal ;

dej txias mechanical seal;

roj lubrication mechanical foob;

tsis muaj lub voj voog xau pressurized mechanical seal;

Khoom siv: hard alloy, silicon carbide, graphite, thiab lwm yam.

Sealing O nplhaib khoom:

fluorine roj hmab, fluorine roj hmab, perfluoro ether, thiab lwm yam.

Nco tseg:

tshwj xeeb tej yam kev mob yuav nruab nrog packing foob.

CFA Mixing system:

Lub peev xwm me me thiab ua tib zoo tswj ntawm lub vijtsam digital.

Dynamic mixer yog sib xws.

Inline mixer rau dubbed thiab zoo sib tov.

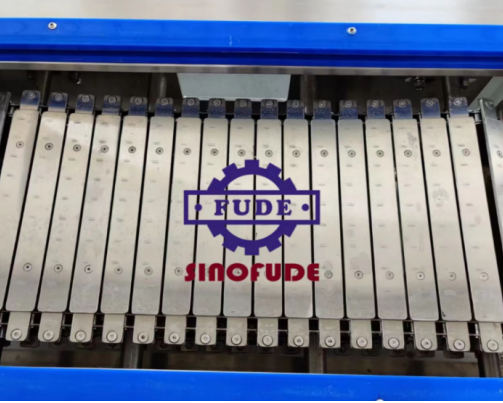

TXOJ CAI SYSTEM

Muaj xws li:

1. Roj Txau system

2. Servo Tsav System rau Pwm

3. Servo Driven Depositing system

4. PLC thiab HMI tswj qhov system

5. Ncej thiab npog

Qhov zoo ntawm SINOFUDE depositing tshuab:

1. Roj Hopper tsho nrog hluav taws xob cua sov kom zoo dua thiab nruab nrab cua sov

2. Depositor thav duab, Ncej, bearing tag nrho yog SUS304, zaub mov tiv tauj yog SUS316L.

3. Txhua qhov vuam rau cov khoom noj sib cuag hauv lub hopper yog polished zoo yam tsis muaj lub kaum sab xis tuag.

4. High precision fabrication technology rau deposit piston thiab lub tes tsho tooj liab ua rau qhov sib xws ntawm cov khoom qab zib hnyav. Lawv tag nrho yog ua los ntawm CNC tshuab thiab zoo polished

5. Helical iav lub thawv rau kev tso nyiaj thiab pwm tsav tsheb ua rau nws ua haujlwm zoo.

6. Ib tus neeg nozzles lub khob hliav qab cov tshuaj tsuag cov roj rau cov kab noj hniav ntawm pwm, kom txuag roj thiab huv.

7. Muab cov khoom zoo li qub thiab Dynamic tov nrog piston hom dosing twj kom zoo dua sib xyaw nrog cov xim thiab tsw thiab lwm yam khoom xyaw. (kev xaiv)

8. Tshwj xeeb tsim manifold thiab nozzles ua rau tus Tsov tus tw dawb.

9. Cov xwm txheej ntawm txhua qhov chaw saib hauv HMI muaj.

Txhim kho qhov kev pab cuam ntawm PID tswj rau txhua qhov chaw siab raug kub tswj.

Qee cov ntsiab lus: Tag nrho cov txheej txheem PLC, thiab kev tswj xyuas qhov deb. PLC Siemens hom.

COOLING SYSTEM

Muaj xws li:

1. SUS304 stainless hlau pwm nqa saw nrog txuas rau pwm kho

2. Chain hom demoulding nrog txhuam thiab cua Blower rau 100% Demoulding

3. Txias qhov ncej ncej thiab npog nrog rwb thaiv tsev

4. Chilling system

5. Outgoing conveyor (PU siv nrog pob zeb diamond nto)

6. Hluav taws xob tswj qhov system

Qhov zoo ntawm SINOFUDE txias qhov:

1. Ntev hom customized AHU es tsis txhob tus qauv luv hom ntsia tau rau hauv lub qhov txias txias kom zoo dua txias txias.

2. Freon yuav yog R134A lossis R410A / 404 hloov R22 rau Tebchaws Meskas txoj cai.

3. Chain hom de-molding nrog ob txhuam ntsia thiab nrog cua riam rau 100% de-molding.

4. Kev tso tawm sai tsim pwm nqa cov saw nrog cov pwm tso tawm sai ua rau cov pwm hloov pauv tsis pub dhau 2 ~ 3 teev.

5. Txhua tus qauv tsim kev huv huv thiab IP65 tus qauv hluav taws xob ua rau lub qhov dej ntxuav tau los ntawm kev ntxuav dej.

6. Blue PU siv es tsis txhob dawb PVC.

7. Chilling system nrog de-frost cua sov cov ntsiab lus hauv AHU ua rau cov av noo hauv qhov av qis dua li qub.

8. High quality pwm nqa saw thiab saw saw phaj nrog saw fixing units ua pwm txav smoothly yam tsis muaj teeb meem

9. Cov cua txias tsim nyog rau kev ua haujlwm siab ntawm cov cua txias.

Wider Stainless hlau saw los yog ceev-hloov hom rau kev yooj yim installation phaj yuav tsis puas yooj yim nrog pwm, kom pwm lub neej ntev

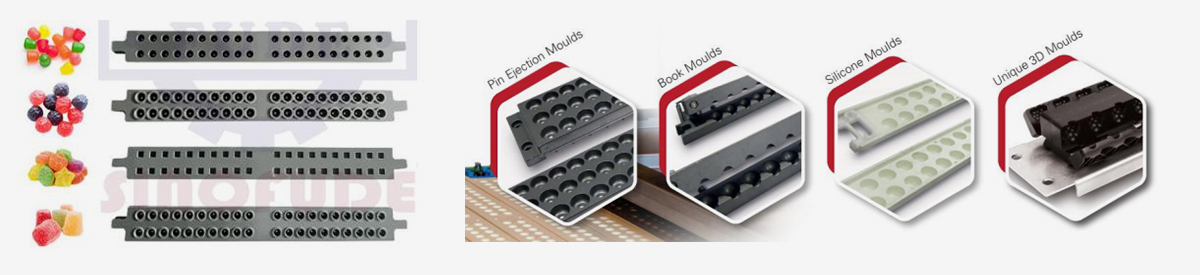

Pwm

Pwm tuaj yeem yog hlau nrog cov txheej tsis-stick lossis silicone roj hmab nrog cov tshuab lossis cua ejection. Lawv tau npaj rau hauv cov seem uas tuaj yeem tshem tau yooj yim rau kev hloov khoom, ntxuav txheej.Cov gummy zoo tuaj yeem kho.

CLM300 hauv peb lub hoobkas

Tshuab zoo zaub

Kev kho mob gummy khoom qab zib los ntawm peb cov neeg siv khoom

Hu rau peb

Cia li tso koj tus email lossis tus lej xov tooj ntawm daim foos tiv tauj kom peb tuaj yeem muab kev pabcuam ntxiv rau koj!ontact form yog li peb tuaj yeem muab kev pabcuam rau koj ntxiv!

Lawv txhua tus tsim raws li cov qauv nruj tshaj plaws thoob ntiaj teb. Peb cov khoom tau txais kev pom zoo los ntawm kev lag luam hauv tsev thiab txawv teb chaws.

Tam sim no lawv tau dav xa tawm mus rau 200 lub teb chaws.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.