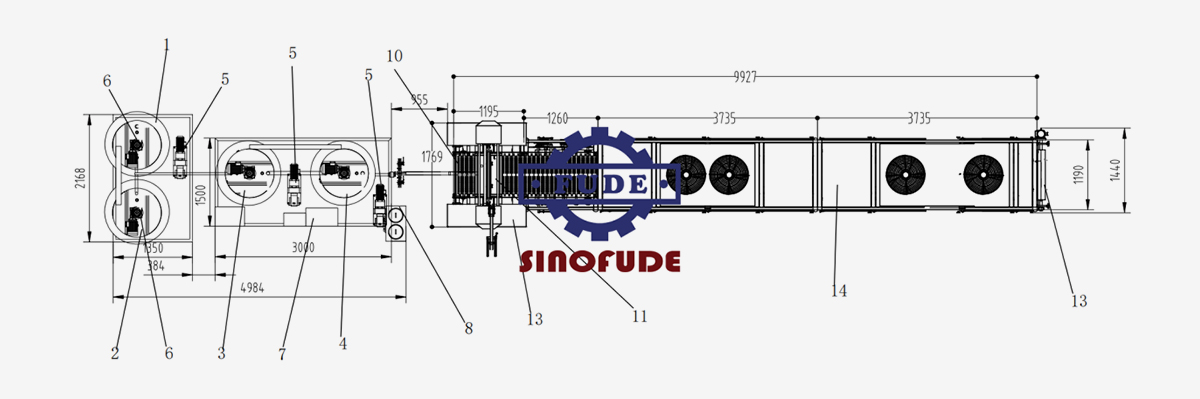

CLM300 yakazara otomatiki gummy candy kugadzira mutsara, iyo inonyanya kukodzera kugadzira iyo inoshanda pipi uye CBD/THC nyoro zvihwitsi. Iyo yakanyanya otomatiki uye inochengetedza nzvimbo yekugadzira mutsara. Panguva imwecheteyo, yakawana akawanda patents uye zvitupa, senge CE uye UL certification. Mutsara wose wekugadzira wakakamurwa kuva 4 zvikamu muhuwandu: 1.cooking system 2.CFA mixing system 3.depositing system 4.cooling system. Hazvina mhosva kuti imhando ipi yepipi yegummy yaunoda kugadzira, michina yedu inogona kuita kuti zviitike. Isu tinogamuchirawo kubvunza kwako kwehunyanzvi.

CLM300 yakazara otomatiki gummy candy kugadzira mutsara, iyo inonyanya kukodzera kugadzira iyo inoshanda pipi uye CBD/THC nyoro zvihwitsi. Iyo yakanyanya otomatiki uye inochengetedza nzvimbo yekugadzira mutsara. Panguva imwecheteyo, yakawana akawanda patents uye zvitupa, senge CE uye UL certification. Mutsara wose wekugadzira wakakamurwa kuva 4 zvikamu muhuwandu: 1.cooking system 2.CFA mixing system 3.depositing system 4.cooling system. Hazvina mhosva kuti imhando ipi yepipi yegummy yaunoda kugadzira, michina yedu inogona kuita kuti zviitike. Isu tinogamuchirawo kubvunza kwako kwehunyanzvi.

Model | CLM300-A |

Capacity | 300 |

Depositing sitiroko (Pcs) | 40 |

Pcs ye molds | 260 Rudzi rwemhando |

Chilling Capacity | 16HP |

Simba remagetsi rinodiwa | 30-60kw |

Kudzvinyirirwa kushandiswa kwemhepo | 0.80m3/min |

Gross huremu (Kgs) | Approx.6000 |

1. Mamiriro ezvinhu anodiwa pakugadzira system: Tembiricha yekamuri 20 ~ 25 ℃, Humidity< 55% | |

Mamiriro/PID:

Main Features:

1. All Stainless simbi SUS304 furemu, chivharo, etc. SUS316 zvokudya kuonana chikamu.

2. Yese yepamberi machining nzira senge CNC, laser yekucheka uye welding, waya

kucheka nezvimwe zvema mechanical zvikamu kugadzira kuvimbisa kushanda kwemutsara wese.

3. Mhando mbiri dzakasiyana dzeCFA system inogona kushandiswa otomatiki kuwedzera ruvara& flavour, kana kuwedzera asidhi vhitamini/THC CBD uye mamwe masimba kana zvinwiwa zvinongedzo.

4. Sarudzo yekuyera uye batching musanganiswa wezvese zvinongedzo, zvinosanganisira CFA, inoshanda zvinoringana nezvimwe.

5. Tekinoroji yemazuva ano yekuronga zvese kutonga uye inoshanda inowanikwa muPLC uye yekubata skrini.

6.Servo system yakanyatsorongeka yekuisa kutonga kwemhando uye shandura mhando dzakasiyana dzemavara maviri kana kuzadza.

7.2D kana 3D gummy iripo nekuchinja kwemasiwiti molds.

8. Kushanda kwakanyanya kwepamusoro kunogona kuwana bhenefiti yakawanda uye kuchengetedza manpower, kurebesa hupenyu hwemuchina.

Equipment list:

SYSTEM YEKUBEKA:

Zvinosanganisira:

1. 3-Layers Fixed Cooker neScrapper Stirrer

2. High Speed Shearing Machine neVFD control

3. Lobe Pombi yekuendesa sirapu yakabikwa

4. Warming kuchengeta system (Mvura tangi, kudziyisa zvinhu, pombi yemvura, tembiricha controller, pombi mavharuvhu etc)

5. 3-mitsara Inotonhorera Tangi ine Scrapper Stirrer

6. 3-layers Storage Tangi ine Scrapper Stirrer

7. Magetsi control cabinet uye Skid frame

Kubatsira kweSINOFUDE cookers:

1. Teflon kukwenya uye kubvongodza kuve nechokwadi chekuchengetedza chikafu

2. 3 akaturikidzana ekudzivirira, zvirinani insulation maitiro, uye chengetedza kuchengetedza kwevashandi

3. High-speed shearing inobvumira kunyunguduka kwakakwana kwemacromolecular raw materials

4. Inogona kubatanidzwa neCIP yekuchenesa system, kuchenesa muchina kuri nyore

Mamwe mashoko:

Lobe Transfer Pombi

Chisimbiso mhando: mechanical chisimbiso chisimbiso Configuration: yakajairika mechanical chisimbiso;

mvura inotonhorera mechanical chisimbiso;

mafuta lubrication mechanical chisimbiso;

hapana leakage cycle yakamanikidzwa mechanical seal;

Material: hard alloy, silicon carbide, graphite, nezvimwe.

Simbisa O mhete zvinhu:

fluorine rabha, fluorine rabha, perfluoro ether, nezvimwe.

Cherechedza:

akakosha mamiriro anogona kuve akashongedzerwa nekurongedza chisimbiso.

CFA Mixing system:

Diki kugona uye nekuchenjera kutonga pane dijitari yekuratidzira skrini.

Dynamic mixer yakanyanya kufanana.

Inline musanganiswa wekusanganisa uye zvirinani kusanganisa.

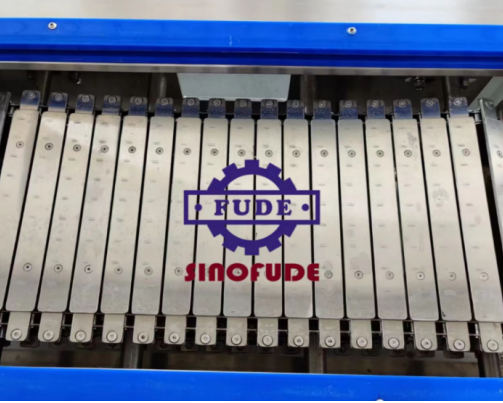

DEPOSITING SYSTEM

Zvinosanganisira:

1. Oil Spraying system

2. Servo Inotungamirirwa System yeMould

3. Servo Driven Depositing system

4. PLC uye HMI controlled system

5. Frame uye Zvivharo

Kubatsira kweSINOFUDE kuisa muchina:

1. Oil Hopper bhachi nemagetsi kudziyisa zviri nani uye avhareji kudziya

2. Depositor furemu, Shaft, inotakura zvese iSUS304, chikafu chekubata chiri SUS316L.

3. Yese welding yekubata chikafu muhopper inokwenenzverwa zvakanaka pasina hutsanana akafa angle.

4. Yakanyanya kurongeka yekugadzira tekinoroji yedhipoziti piston uye maoko emhangura inoita kuenderana kwehuremu hwemapipi. Iwo ese anogadzirwa neCNC muchina uye akakwenenzverwa

5. Helical giya bhokisi rekuisa uye mold kutyaira inoita kuti ishande zvakanaka.

6. Munhu ega ega makoni chimiro anopfapfaidza mafuta kumakomba e mold, kuchengetedza mafuta uye hutsanana mamiriro.

7. Sanganisa Static uye Dynamic Musanganiswa nepiston mhando dosing pombi yekusanganisa zvirinani nemuvara uye kuravira uye zvimwe zvinongedzo. (sarudzo)

8. Yakakosha dhizaini yakawanda uye nozzles inoita kuti muswe usununguke.

9. Mamiriro echikamu chimwe nechimwe chekutarisa muHMI chiripo.

Yakavandudzwa chirongwa chePID kutonga kune yega yega chikamu chakanyanya kurongeka tembiricha yekudzora.

Mamwe ruzivo: Yakazara seti yePLC system, uye chinhambwe chekudzora system. PLC Siemens mhando.

KUTONHORA SYSTEM

Zvinosanganisira:

1. SUS304 simbi isina tsvina mold inotakura Chain ine attachment yekugadzira mold

2. Chain type demoulding nebrashi nemhepo blower ye 100% Demoulding

3. Kutonhodza tunnel furemu uye kufukidza nekudzivirira

4. Chilling system

5. Inobuditsa conveyor (PU bhandi rine diamondi pamusoro)

6. Magetsi anodzora hurongwa

Kubatsira kweSINOFUDE kutonhora mugero:

1. Rudzi rurefu rwakagadziridzwa AHU pachinzvimbo cheyakajairwa mhando pfupi yakaiswa mugero rekutonhodza kuitira kutonhora kuri nani.

2. Freon ichave R134A kana R410A/404 pachinzvimbo cheR22 yeUSA inodiwa.

3. Chain type de-molding ine mabhurashi maviri akaiswa uye nemhepo banga re 100% de-molding.

4. Kurumidza kuburitsa dhizaini mold inotakura cheni ine nekukurumidza kuburitsa mhando mold inoita kuti mold shanduko ingori mukati me2 ~ 3hours.

5. Yese sanitary dhizaini chimiro uye IP65 yemagetsi chiyero inoita kuti mugero ugezeke nekugeza mvura.

6. Bhandi reBlue PU pane chena PVC.

7. Chilling system ine de-frost yekudziya zvinhu muAHU inoita kuti humidity mumugero hudzike pane zvakajairika.

8. Yemhando yepamusoro mold inotakura cheni uye cheni inotungamira ndiro ine cheni yekugadzirisa mayunitsi inoita kuti mold ifambe zvakanaka pasina dambudziko.

9. Kuyerera kwemhepo yakatonhodzwa kunonzwisisika kuitira kushanda kwepamusoro kwekutonhodza.

Yakakura Stainless simbi cheni kana inokurumidza-kuchinja mhando yekuisa nyore kugadzika ndiro haizokuvadze nyore ne mold, chengetedza mold hupenyu hurefu.

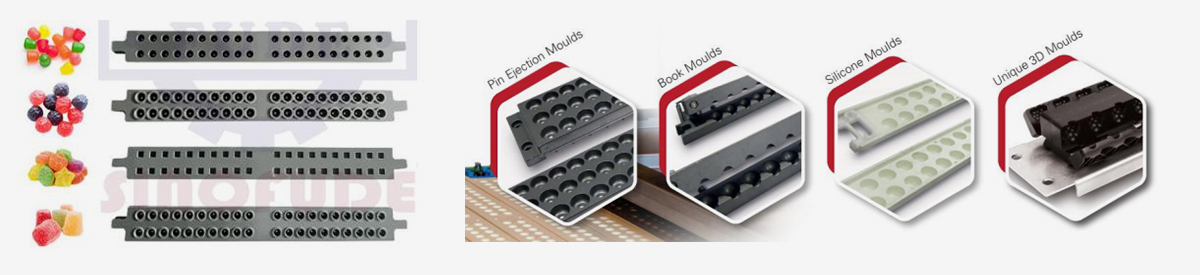

Molds

Molds inogona kuve yesimbi ine isina-tsvimbo yekupotera kana silicone rabha ine mechanical kana mhepo ejection. Izvo zvakarongwa muzvikamu zvinogona kubviswa nyore nyore pakushandura zvigadzirwa, kuchenesa coating.Iyo gummy shape inogona kugadziriswa.

CLM300 mufekitari yedu

Kuratidzwa kwemhando yemuchina

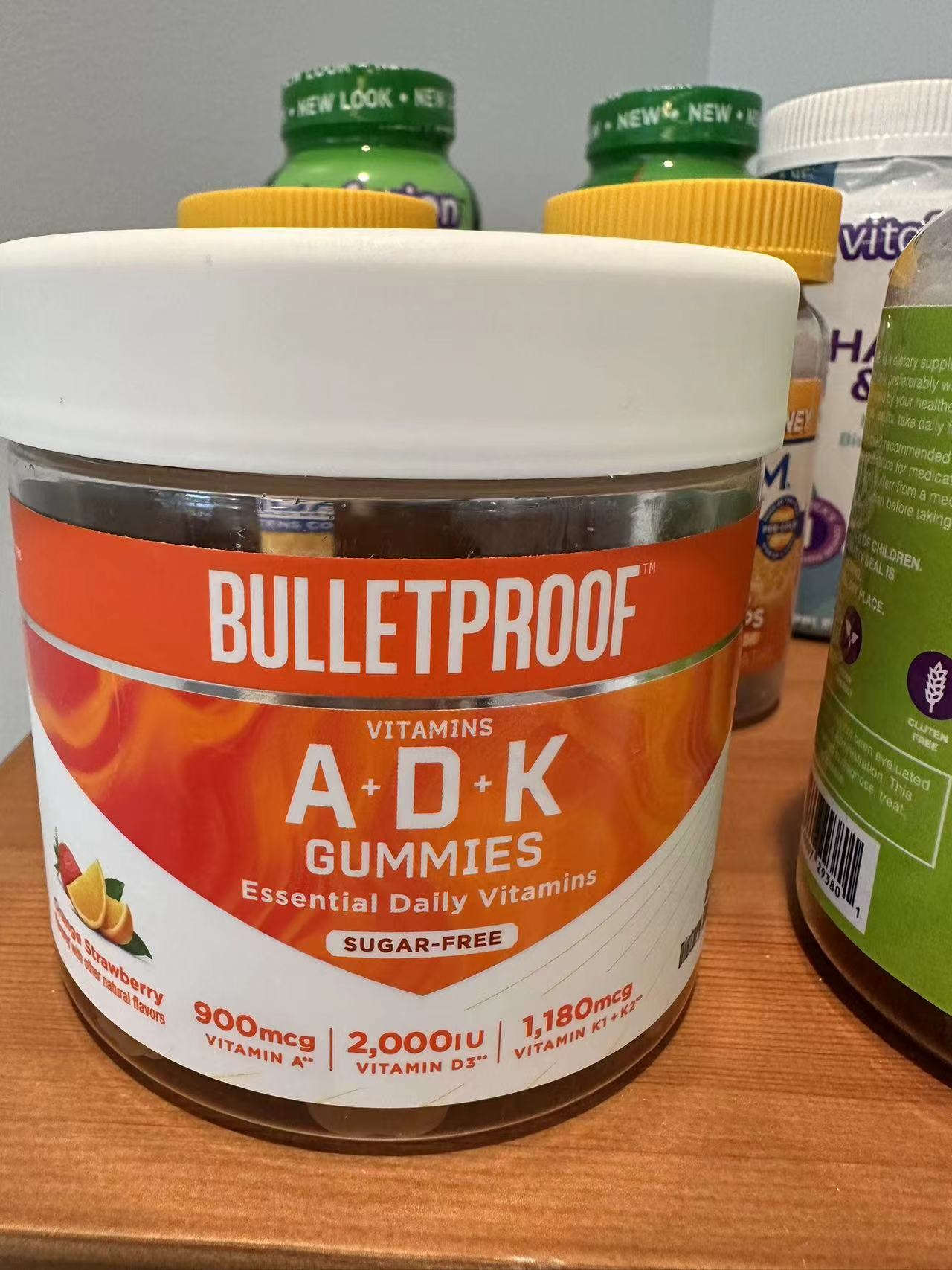

Utano hwekuchengetedza gummy zvihwitsi zvigadzirwa kubva kune vatengi vedu

Bata Nesu

Ingosiya email yako kana nhamba yefoni pafomu rekuonana kuti tikupe mamwe masevhisi!ontact fomu kuti tikupe mamwe masevhisi!

Zvose zvinogadzirwa maererano nemitemo yakasimba yenyika. Zvigadzirwa zvedu zvakawana nyasha kubva kumisika yemukati neyekunze.

Pari zvino vari kuendesa kunze kwenyika zvakanyanya ku200 nyika.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.