CLM300 full automatic gummy candy production line, which especially suitable for making the functional candy and CBD/THC soft candy. It is a highly automated and space-saving production line. At the same time, it has obtained multiple patents and certifications, such as CE and UL certifications. The whole production line is divided into 4 parts in total:1.cooking system 2.CFA mixing system 3.depositing system 4.cooling system. No matter what kind of gummy candy you want to make, our machines can make it happen. We also welcome your technical consultation.

CLM300 full automatic gummy candy production line, which especially suitable for making the functional candy and CBD/THC soft candy. It is a highly automated and space-saving production line. At the same time, it has obtained multiple patents and certifications, such as CE and UL certifications. The whole production line is divided into 4 parts in total:1.cooking system 2.CFA mixing system 3.depositing system 4.cooling system. No matter what kind of gummy candy you want to make, our machines can make it happen. We also welcome your technical consultation.

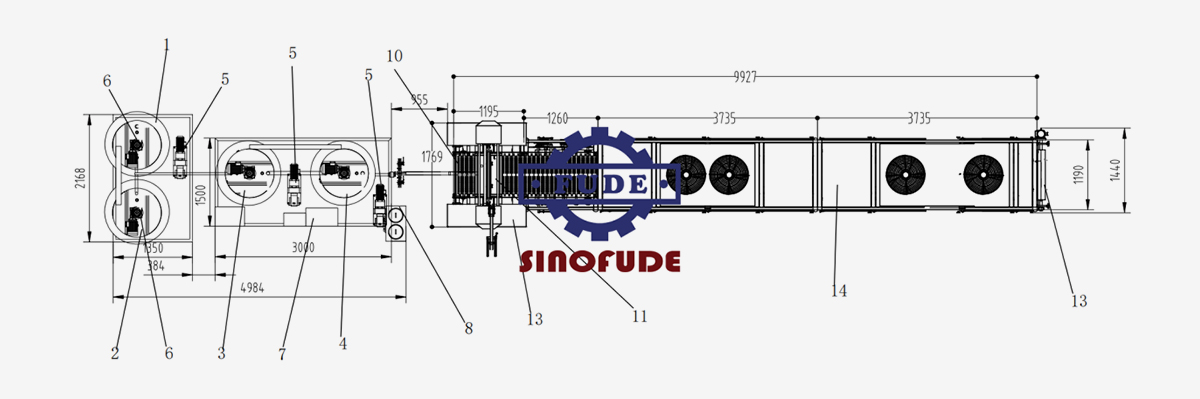

Model | CLM300-A |

Capacity | 300 |

Depositing stroke (Pcs) | 40 |

Pcs of molds | 260 Long type |

Chilling Capacity | 16HP |

Electric power needed | 30-60kw |

Compressed air consumption | 0.80m3/min |

Gross weight (Kgs) | Approx.6000 |

1. Conditions needed for forming system: Room temperature 20~25℃, Humidity < 55% | |

Layout/PID:

Main Features:

1. All Stainless steel SUS304 frame, cover, etc. SUS316 food contact part.

2. All advance machining method like CNC, laser cutting and welding, wire

cutting etc. for mechanical parts making to guarantee the performance of the whole line.

3. Two different types of CFA system can be used for automatic adding color & flavor, or adding acid vitamin/THC CBD and other power or liquid ingredients.

4. Optional for weighing and batching mixing of all ingredients, include CFA, active ingredients etc.

5. Latest technology for programming all control and operates is available in PLC and touch screen.

6.Servo system more accurate for depositing quality control and change different type for two color or fillings.

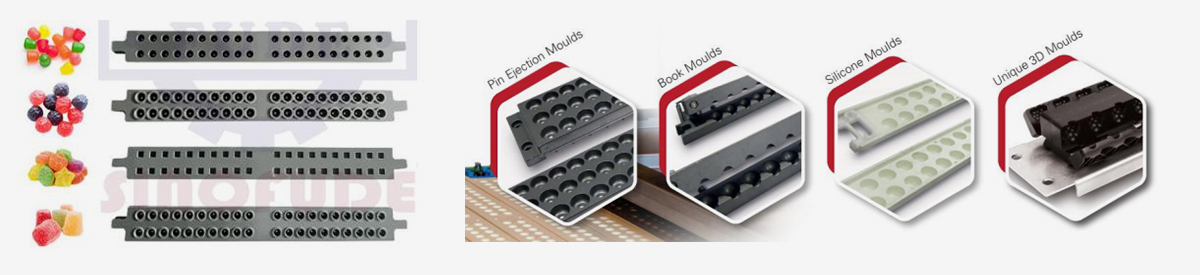

7.2D or 3D gummy are available with changing of candy molds.

8. High efficiency working can gain more benefit and save the manpower, prolong the machine life.

Equipment list:

THE COOKING SYSTEM:

Consists of:

1. 3-Layers Fixed Cooker with Scrapper Stirrer

2. High Speed Shearing Machine with VFD control

3. Lobe Pump for transferring cooked syrup

4. Warming keeping system (Water tank, heating elements, water pump, temperature controller, piping valves etc)

5. 3-layers Cooling Tank with Scrapper Stirrer

6. 3-layers Storage Tank with Scrapper Stirrer

7. Electrical control cabinet and Skid frame

Advantage of SINOFUDE cookers:

1. Teflon scraping and stirring to ensure food safety

2. 3 layers of insulation, better insulation effect, and protect personnel safety

3. High-speed shearing allows perfect melting of macromolecular raw materials

4. Can be connected to CIP cleaning system, machine cleaning is more convenient

Some details:

Lobe Transfer Pump

Seal type: mechanical seal seal Configuration: conventional mechanical seal;

water cooling mechanical seal;

oil lubrication mechanical seal;

no leakage cycle pressurized mechanical seal;

Material: hard alloy, silicon carbide, graphite, etc.

Seal O ring material:

fluorine rubber, fluorine rubber, perfluoro ether, etc.

Note:

special conditions can be equipped with packing seal.

CFA Mixing system:

Small capacity and meticulous control on digital display screen.

Dynamic mixer is more uniform.

Inline mixer for dubbed and better mixing.

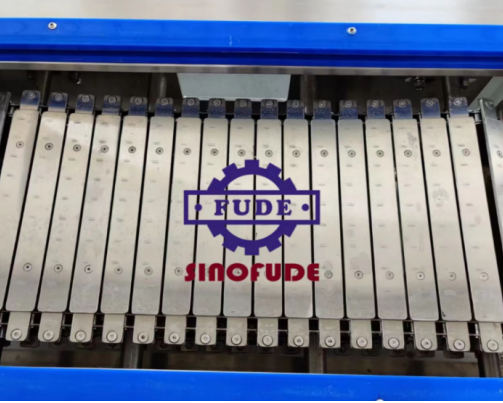

DEPOSITING SYSTEM

Consists of:

1. Oil Spraying system

2. Servo Driven System for Mold

3. Servo Driven Depositing system

4. PLC and HMI controlled system

5. Frame and Covers

Advantage of SINOFUDE depositing machine:

1. Oil Hopper jacket with electrical heating for better and average warming

2. Depositor frame, Shaft, bearing all are SUS304, food contact are SUS316L.

3. All welding for food contact in the hopper are polished well without any hygienic dead angle.

4. High accuracy fabrication technology for deposit piston and copper sleeves makes the consistency of candy weight. They are all made by CNC machine and fine polished

5. Helical gear box for depositing and mould driving makes it works smoothly.

6. Individual nozzles cone shape spray the oil to cavities of mold, for saving oil and sanitary condition.

7. Combine Static and Dynamic Mixer with piston type dosing pump for much better mixing with color and flavor and other ingredients. (option)

8. Special design manifold and nozzles makes tail free.

9. Status of each parts monitor in HMI is available.

Improved program of PID control for each parts high accuracy temperature control.

Some details: Full set of PLC system, and distance control system. PLC Siemens brand.

COOLING SYSTEM

Consists of:

1. SUS304 stainless steel mould carry Chain with attachment for mould fixing

2. Chain type demoulding with brush and air blower for 100% Demoulding

3. Cooling tunnel frame and cover with insulations

4. Chilling system

5. Outgoing conveyor (PU belt with diamond surface)

6. Electrical controlling system

Advantage of SINOFUDE cooling tunnel:

1. Longer type customized AHU instead of standard short type installed in the cooling tunnel for better cooling affection.

2. Freon will be R134A or R410A/404 instead of R22 for USA policy requirement.

3. Chain type de-molding with two brushes installed and with air knife for 100% de-molding.

4. Quick release design mould carrying chain with quick release type mould makes the mould changeover just within 2~3hours.

5. All sanitary design structure and IP65 electrical standard makes the tunnel washable by washing water.

6. Blue PU belt instead of white PVC.

7. Chilling system with de-frost heating elements in AHU makes the humidity in tunnel lower than normal.

8. High quality mould carry chain and chain guide plate with chain fixing units makes mould moving smoothly without any problem

9. Reasonable cooled air flow for high performance of cooling.

Wider Stainless steel chain or quick-change type for easy installation plate will not damage easily with the molds, keep mold longer life

Molds

Molds can be metal with a non-stick coating or silicone rubber with either mechanical or air ejection. They are arranged in sections that can be easily removed for changing products, cleaning coating.The gummy shape can be customized.

CLM300 in our factory

Machine quality display

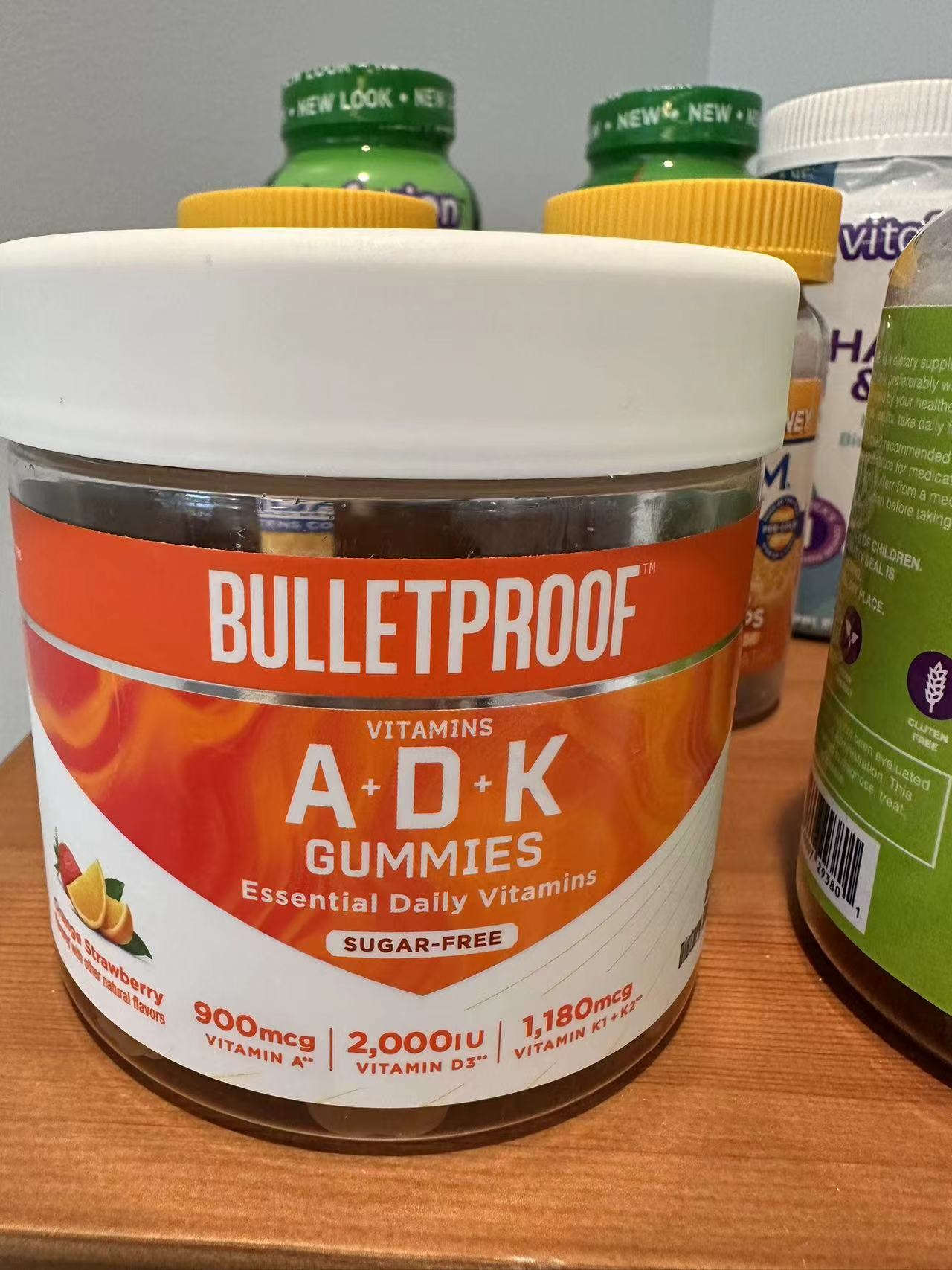

Health care gummy candy products from our customers

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.