GCT licorice Candy Production Line

Our unique design for a licorice candy production line empowers confectionery manufacturers to unlock their creativity, optimize productivity, and deliver exceptional candy products to the market. Embrace the future of licorice candy production with our innovative design and experience the transformative impact on your manufacturing capabilities.

About SINOFUDE

Shanghai Fude Machinery Manufacturing Co., Ltd., formerly known as Shanghai Chunqi Machinery Factory, belongs to Bory Industrial Group. It is located in Huqiao Town Industrial Park, Fengxian District, Shanghai, with convenient transportation and beautiful environment. The company brand name SINOFUDE was founded in 1998. As a well-known food and pharmaceutical machinery brand in Shanghai, after more than 20 years of development, it has developed from one factory to three factories with a total area more than 30 acres and more than 200 employees. SINOFUDE introduced the ISO9001 management system for management in 2004, and most of its products have also passed the EU CE and UL certification. The company's product range covers all kinds of high-quality production line for chocolate, confectionery, and bakery production. 80% of the products are exported More than 60 countries and regions in Europe, America, Southeast Asia, Eastern Europe, Africa, etc.

The machine is mainly used for making fondant masses, it is simple to use fondant-beating machine. Sugar, glucose, water is dissolved then put into the hopper of the fondant beater. The beater is turned on and the cooked syrup is fed into the creaming screw. The sugar syrup is then agitated in a controlled way to seed the syrup into a fine fondant paste. The machine has a capacity of 50~500kg per hour and is ideal for a entry level machine. The unit has heated hopper and a jacketed barrel for cooling.

| Model | GCT-300 | GCT-500 | GCT-1000 |

| Belt speed | 1-10m/min | 1-10m/min | 1-10m/min |

| Capacity | 300kg/h | 500kg/h | 1000kg/h |

| Cooling Temp.(℃) | 2-10 | 2-10 | 2-10 |

Unique design:

We are proud to announce our revolutionary design for a licorice candy production line, setting new standards in creativity, efficiency, and product quality. Our unique design combines cutting-edge technology with customizable features, allowing confectionery manufacturers to unleash their creativity and streamline their production processes. Let us take you on a journey through the remarkable features of our licorice candy production line.

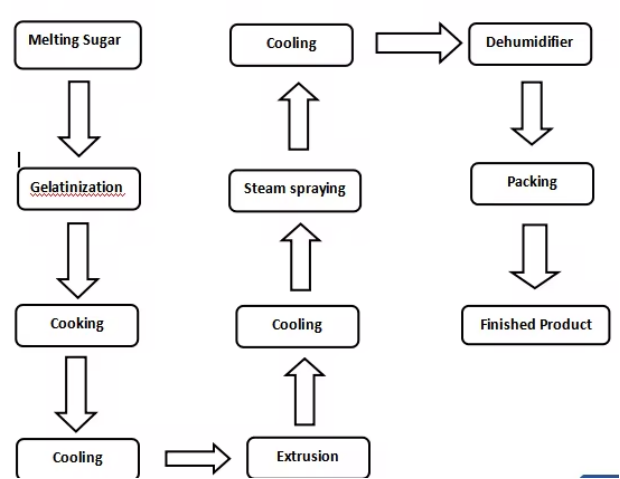

1. Modular and Customizable Configuration: Our production line design adopts a modular approach, offering flexibility and customization options to meet diverse production requirements. Each module can be tailored to specific functionalities, such as mixing, forming, cooling, coating, and packaging. Manufacturers can choose and arrange modules according to their unique needs, ensuring a seamless and efficient workflow.

2. Advanced Mixing and Dispensing System: Our licorice candy production line is equipped with an advanced mixing and dispensing system that ensures precise ingredient measurement and consistent blending. The system allows for accurate dosing of licorice extract, sweeteners, flavorings, and other additives, guaranteeing a homogeneous mixture and uniform taste in every candy.

3. Innovative Forming Technology: We have incorporated state-of-the-art forming technology into our production line design. This technology enables the creation of various licorice candy shapes, including ropes, twists, braids, or custom designs. The forming process ensures excellent texture and consistency, enhancing the overall sensory experience of the candies.

4. Intelligent Cooling and Conditioning: Our licorice candy production line features an intelligent cooling and conditioning system. This system optimizes the cooling process, reducing production time while maintaining the ideal temperature and humidity conditions for candy solidification. The result is perfectly shaped and stable candies that retain their flavor and texture.

5. Versatile Coating and Polishing Options: To meet diverse market demands, our production line design offers versatile coating and polishing options. With our integrated coating and polishing modules, manufacturers can choose from a range of coatings, such as sugar, chocolate, or even innovative flavors and textures. This customization elevates the visual appeal and taste of the licorice candies, captivating consumers with unique and delightful experiences.

6. Automated Packaging and Quality Control: Our licorice candy production line includes automated packaging and quality control systems to streamline the final stages of production. Advanced packaging machines ensure efficient wrapping and sealing of candies, reducing manual labor and enhancing hygiene. In addition, integrated quality control mechanisms continuously monitor production parameters, ensuring consistent quality and adherence to specifications.

7. User-Friendly Interface and Data Analytics: To simplify operations and optimize production efficiency, our production line design incorporates a user-friendly interface and data analytics capabilities. Operators can easily control and monitor various production parameters, access real-time data, and make informed decisions to improve productivity and quality.

8. Scalability and Future-Readiness: Our licorice candy production line design is scalable, allowing manufacturers to expand their production capacity as needed. Additionally, we have designed the line with future-readiness in mind, enabling seamless integration of emerging technologies or process improvements, ensuring long-term sustainability and competitiveness.

FAQ

1.Can the equipment be installed under hot weather?

Yes, there is not any requirement for kitchen unit, but for forming or cooling unit, some of the machine need to be placed in a air conditioned room.

2.Can Your products be installed under the cold weather?

Yes, there is not any requirement for kitchen unit, but for forming or cooling unit, some of the machine need to be placed in a air conditioned room.

3.You have sales target finished amount requirement to the distributor?

It is depend on the market and products.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.