A modern SINOFUDE marshmallow production line is designed to produce high-quality marshmallows with stable texture, precise shape, and consistent aeration. Whether you are manufacturing traditional rope-type marshmallows, twisted marshmallows, shaped marshmallows, or filled marshmallow products, choosing the right system—extrusion marshmallow making machine or deposited marshmallow production line—is essential for achieving efficient and reliable production.

This document introduces the complete workflow, machine configuration, technical features, and benefits of each marshmallow system, helping factories and brand owners select the best solution for their production needs.

1. Overview of Marshmallow Manufacturing

Marshmallow production mainly involves four core processes:

1. Ingredient cooking (syrup cooking and gelatin hydration)

2. Continuous aeration to create the fluffy structure

3. Forming — via extrusion or depositing

4. Cooling, cutting, dusting, and packaging

A complete marshmallow line integrates cooking, mixing, forming, cooling, shaping, and packing into a continuous, sanitary, and efficient workflow. This ensures consistent quality, reduces labor cost, and improves production capacity.

2. Extrusion Marshmallow Making Machine

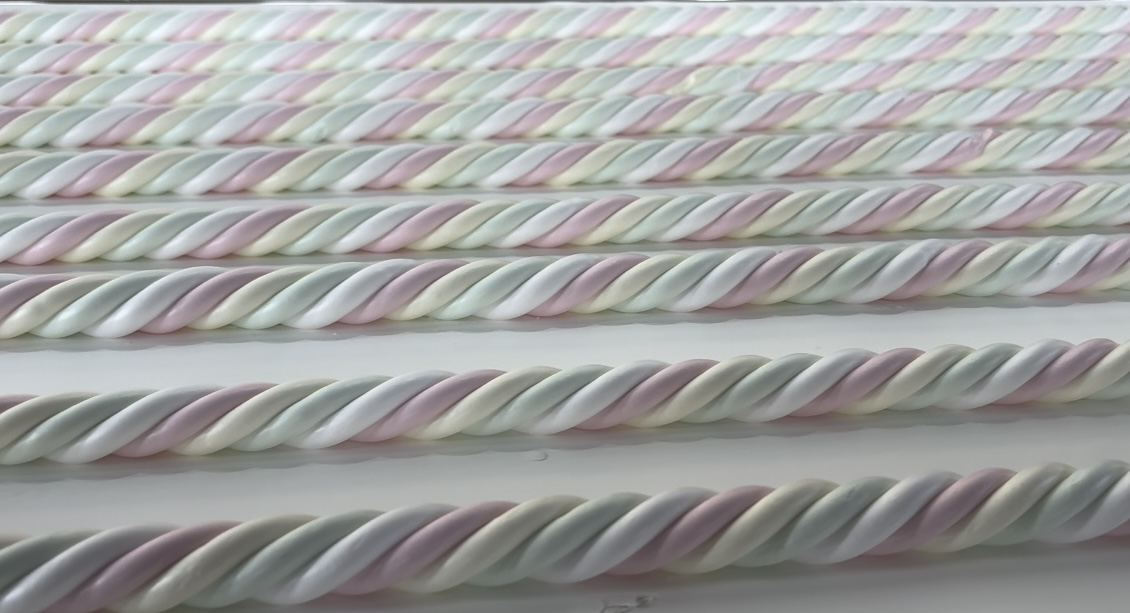

The extrusion marshmallow making machine is widely used for producing rope-type marshmallows, rainbow twisted marshmallows, cylindrical marshmallows, bar shapes, and multi-color patterns. It is suitable for medium-to-large factories seeking stable mass production.

Key Features:

- High efficiency & continuous production

- Multi-color and multi-lane extrusion

- Uniform rope diameter

- Automatic cutting system

- Optional powder coating system

Typical Capacity Range: 80 kg/h to 500 kg/h or higher.

3. Deposited Marshmallow Production Line

The deposited marshmallow production line is ideal for shaped marshmallows, filled marshmallows, and premium marshmallow candies.

Key Features:

- High-precision depositing

- Supports filled marshmallows

- Suitable for creative shapes

- More delicate texture

- Optional automatic starch handling

Capacity Range: 150 kg/h to 600 kg/h.

4. Core Components of a Complete Marshmallow Production Line

- Sugar & Gelatin Dissolving System

- Continuous Cooker

- Aeration / Whipping Machine

- Color & Flavor Dosing Unit

- Forming System (Extruder or Depositor)

- Cooling Tunnel

- Cutting, Dusting & Coating Unit

- Automatic Packaging Machine

5. Advantages of Modern Marshmallow Production Lines

- High level of automation

- Consistent quality

- Easy operation & maintenance

- Customization options

- Food-grade stainless steel construction

6. Applications of Marshmallow Production

- Twisted marshmallows

- Rainbow rope marshmallows

- Marshmallow bars & cubes

- Mini hot chocolate marshmallows

- Shaped marshmallows

- Filled marshmallows

- Seasonal marshmallow candies

Conclusion

Choosing between extrusion and deposited marshmallow lines depends on product type, flexibility, and production goals. Both systems provide efficient, hygienic, and fully automated solutions for global confectionery manufacturers.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.