Under its BCM BAKING brand, SINOFUDE now offers a fully automatic biscuit and cookie line – from dough feeding and forming to baking, cooling and stacking – for industrial bakeries worldwide.

[Shanghai, China – Date] – Shanghai SINOFUDE Machinery, a well-known Chinese manufacturer of confectionery and snack production lines, is expanding its portfolio in the bakery sector through its dedicated brand BCM BAKING.

The company has launched a new Automatic Biscuit & Cookies Production Line designed for industrial biscuit factories and large bakeries that require stable quality, high efficiency and flexible layout solutions. Positioned under the SINOFUDE group, BCM BAKING focuses specifically on bread, cake, biscuit and cookie equipment, while SINOFUDE continues to lead in gummy, chocolate, marshmallow, popping boba and other confectionery lines.

Complete Line Concept From Dough to Cooling & Stacking

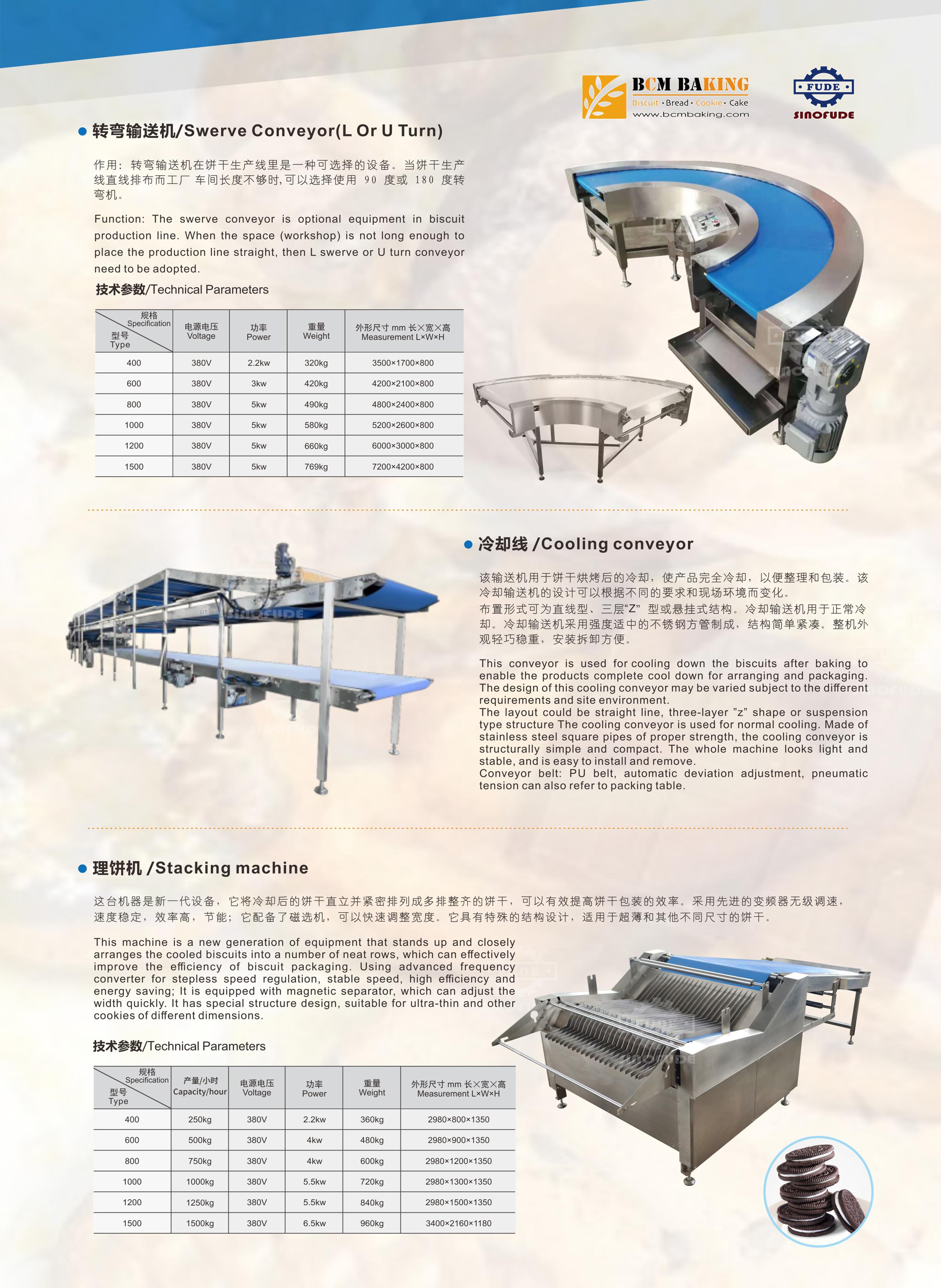

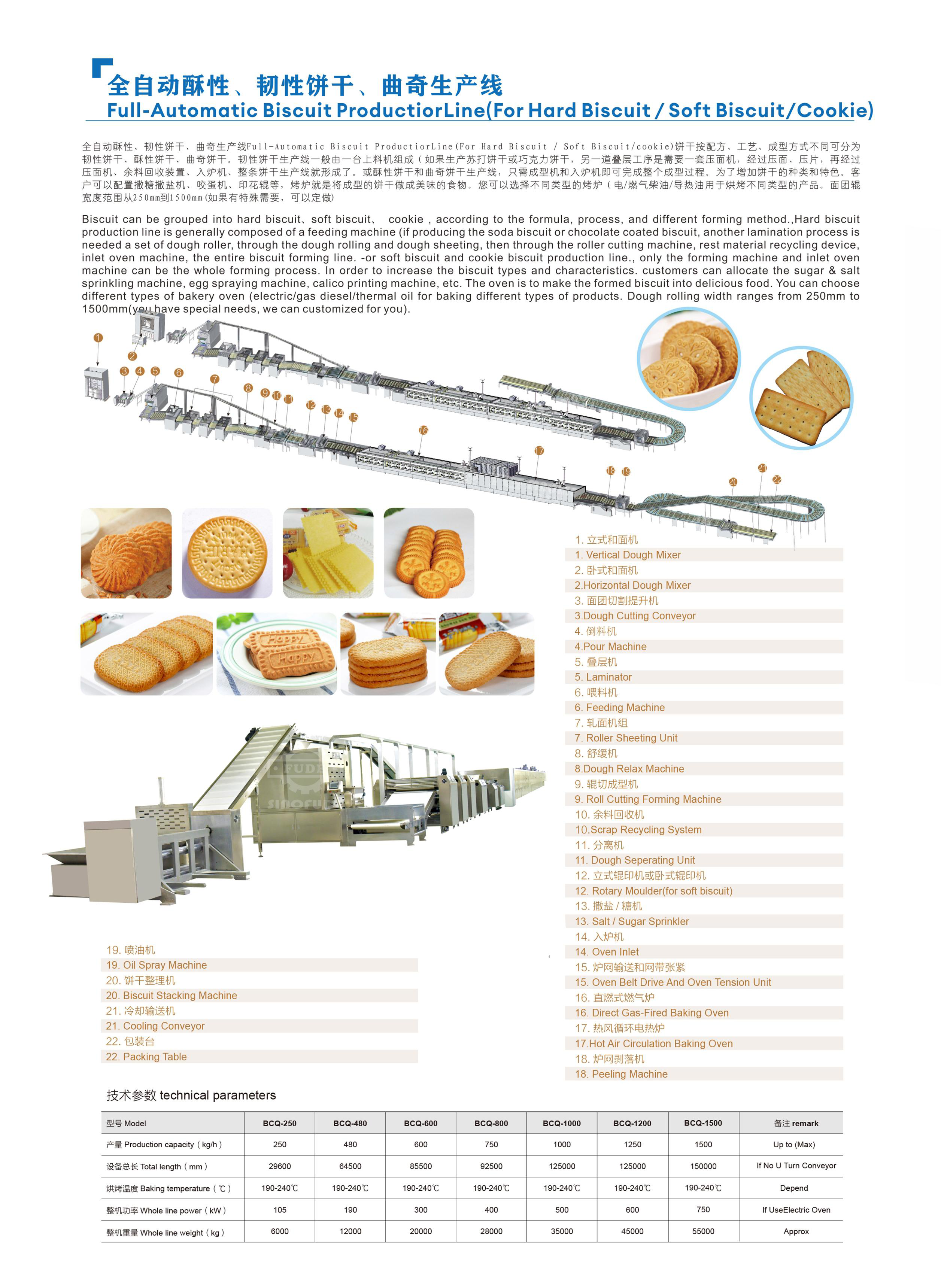

The BCM BAKING Automatic Biscuit & Cookies Production Line is engineered as a modular, fully automatic system that covers every key step of production:

· Dough feeding / dough table – Dough from the mixer is safely lifted and poured into a U-shaped dough table. Controlled feeding ensures a continuous and even dough supply to the forming section.

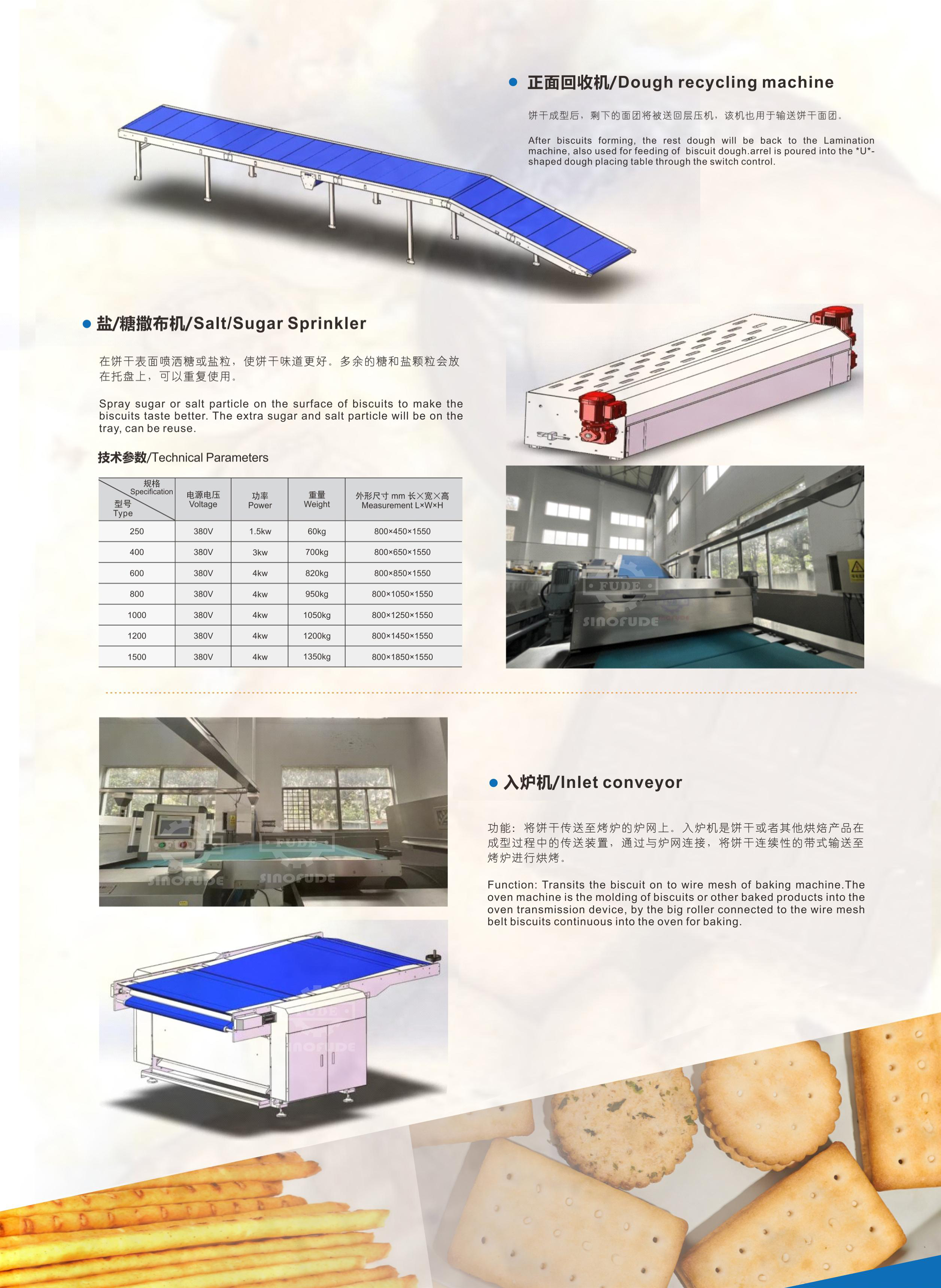

· Sheeting, forming and separating – The line combines sheeting, gauging and roll cutting / rotary moulding to form hard or soft biscuit pieces. A dedicated separating unit keeps biscuit pieces intact while separating and collecting the scrap dough.

· Scrap / dough recycling conveyor – Scrap dough is automatically returned to the front section of the line, minimizing waste and keeping the process continuous.

· Sugar / salt sprinkler (optional) – A sprinkler unit can evenly apply sugar, salt or seeds to the surface of biscuits. Sprinkling volume and coverage are adjustable to match different recipes and market preferences.

· Inlet conveyor to tunnel oven – A specially designed inlet conveyor transfers the biscuit pieces smoothly onto the wire mesh of the tunnel oven, ensuring stable loading and consistent baking conditions.

· L- or U-shape turning conveyor (optional) – For plants with limited length, BCM BAKING offers L- or U-turn conveyors so the whole line can be arranged flexibly without sacrificing capacity.

· Cooling conveyor and automatic stacking – After baking, biscuits pass through cooling conveyors and are then arranged by an automatic stacking unit. The stacking system aligns biscuits neatly for efficient manual or automatic wrapping and packing.

· Cookie depositor integration – For customers who also produce deposited or wire-cut cookies, a BCM BAKING cookie depositor can be integrated into the line, enabling die extrusion, nozzle dropping and wire cutting with a wide variety of shapes and patterns.

Hygienic, Easy to Clean and Operator-Friendly

As a brand under SINOFUDE, BCM BAKING follows the same design principles of hygiene, reliability and easy maintenance. The line uses stainless-steel frames and food-grade contact parts, with open, accessible structures for cleaning and inspection. Stable belt support and auto tracking reduce manual adjustment, while mechanical and electrical safety protections help keep operators safe.

Capacity Range and Custom Layout

According to the line configuration, typical capacities cover medium to large-scale industrial production, with options in working width, oven length and number of cooling or stacking sections. BCM BAKING can design layouts according to the customer’s existing workshop, provide straight-line, L-shape or U-shape configurations, and adjust product parameters for different biscuit and cookie types. Voltage and electrical standards can be adapted to local requirements in Asia, the Middle East, Europe, Latin America and other regions.

Backed by SINOFUDE’s Global Experience

With SINOFUDE’s long experience in exporting confectionery and snack machinery, BCM BAKING benefits from a mature international service system. Services include pre-sales consultation, layout and capacity planning, factory testing and FAT in China, on-site or remote commissioning support, operator training, as well as after-sales service and spare-parts support.

“Our BCM BAKING biscuit and cookie line is a natural extension of SINOFUDE’s technology into the bakery sector,” said a spokesperson for SINOFUDE. “We want to provide overseas customers with a practical, fully automatic solution that is easy to operate, easy to clean, and flexible enough to fit different factory layouts.”

Selected views from the BCM BAKING biscuit & cookies production line:

About SINOFUDE

SINOFUDE (Shanghai Fuda Machinery) is a Chinese manufacturer specializing in complete production lines for gummy candy, hard candy, chocolate, marshmallow, popping boba and other confectionery products. With years of export experience and installations in many countries, SINOFUDE provides turnkey solutions from process design and equipment manufacturing to commissioning and training.

About BCM BAKING

BCM BAKING is the bakery equipment brand under SINOFUDE, focusing on industrial lines for bread, cake, biscuits and cookies. The BCM BAKING portfolio includes dough mixers, tunnel ovens, cookie depositors and complete biscuit production lines, helping bakeries upgrade their automation level and product quality.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.