SINOFUDE is proud of the machine design with sanitary and easy washing structure for Gummy candy with CBD or THC or Vitamin and Minerals. Etc functional products. It is ideal equipment that can produce good quality gummies with the saving of both the manpower and the space occupied. Shanghai Fuda soft candy machinery can make gummy candies of different shapes and flavors, and a variety of molds can be customized. The configuration, length, height, etc. of a whole soft candy production line can also be designed according to the customer's needs and the size of the factory.

Gummy candy machines are divided into semi-automation and fully-automation. Semi-automatic machines including CHX20- 20-50kg/h, baby depositor -25kg/h. Fully-automatic machines including CLM80Q--60-80kg/h, CLM150--150kg/h, CLM300--300kg/h, CLM450--450kg/h, CLM600--600kg/h.

Provide you with a one-stop solution from soft candy cooking and shaping to processing. You can use various gummies produced by our gummy production line: gummy bears, pectin gummies, gelatin gummies, carrageenan gummies, etc.

The soft candy casting production line uses syrup and gelatin or pectin as raw materials to complete the production of various shapes of soft candies through the boiling, concentration, pouring and cooling molding of the soft candy casting production line. The soft candy casting production line improves the efficiency of soft candy production. Thereby saving labor costs.

The advantages of Shanghai Fuda gummy candy production line:

1. Fast pouring, fast cooling, and fast production speed;

2. High production precision;

3. Splendid technology;

4. Convenient replacement of parts;

5. Perfect after-sales system;

6. Product quality is good, comparable to similar products in Europe;

Why choose the gummy candy production line of Shanghai Fuda Machinery?

1.More than 20 years of candy machinery production experience;

2.One-stop service integrating product design and development, production and sales, installation, technical training and after-sales;

3.World class product quality;

4.Higher-end quality, more competitive price;

The raw material handling system mainly includes sugar boiling and syrup storage. The cooked syrup is transported to the storage barrel through an insulated pipe and a gear pump, and then the syrup in the storage barrel is transported to the pouring hopper through an insulated pipe and a rotor pump.

All cooking pots have mechanical seals on the top to prevent dust and impurities from falling into the country. The interior of all pots is mirror polished and easy to clean. Stir while scraping Teflon.

All pots and tanks are placed on a stainless steel frame, which can keep the production environment clean and tidy during the production process and easy to clean. The entire cooking system and pouring machine are controlled separately with separate electrical boxes. Easy to control.

All tanks are made of food-grade 304 stainless steel. Flavor and color bottles can optionally be installed on this rack. The flavor and color mixing system uses a dosing pump and a static mixer to ensure uniform color of the mixed syrup. The amount of pigments and flavors can be adjusted at will.

The heating method can be electric heating or steam heating.

Outstanding advantages:

1. The pouring head has been improved, and the pouring quantity is more accurate and reliable. The replacement and operation of the punch are simple and convenient, and individually adjustable. The stroke of all punches (sugar granule weight) can be adjusted online.

2. The insulation hopper has electric heating control, and the temperature controller PID trapezoidal temperature control is accurate and can be set arbitrarily.

3. The cooling tunnel has been improved. The entire refrigeration machine is assembled in the freezer with a unified height, the length of the tunnel is lengthened, and the appearance is beautiful. The cooling effect is better than that shown in the figure, and the temperature control is more accurate. This freezer is equipped with a defrost device.

4. The demoulding mechanism is original to our company, with a tank chain structure and a rotating brush to ensure complete demoulding.

Advance type machine equipped with 2 layer cooling, the air recycling system and mold convey system separated by a stainless steel clapboard, which prevent the dust drop to the candy surface.Cold air will convey to the candy convey system by the 2 end of the cooling tunnel.The 2 guide rail of the back side of the cooling tunnel equipped with automatic tension device, which protect the chain and prolong the service life. Demold device with tank chain demolding and brush.

PU conveyor with diamond pattern, which prevent the candy stick on the conveyor, it’s easy to clean and with longer service life. Frame adopts triangle slope format, with crossbeam protruding. All parts with individual control, which is easy to assemble, just a simple wire connection can start the machine, all machines will be tried and commission in factory before shipment so that the end user can run the machine directly.Sugar coating or oil coating is optional if customer need, the candy will be conveyed directly to the coating machine.

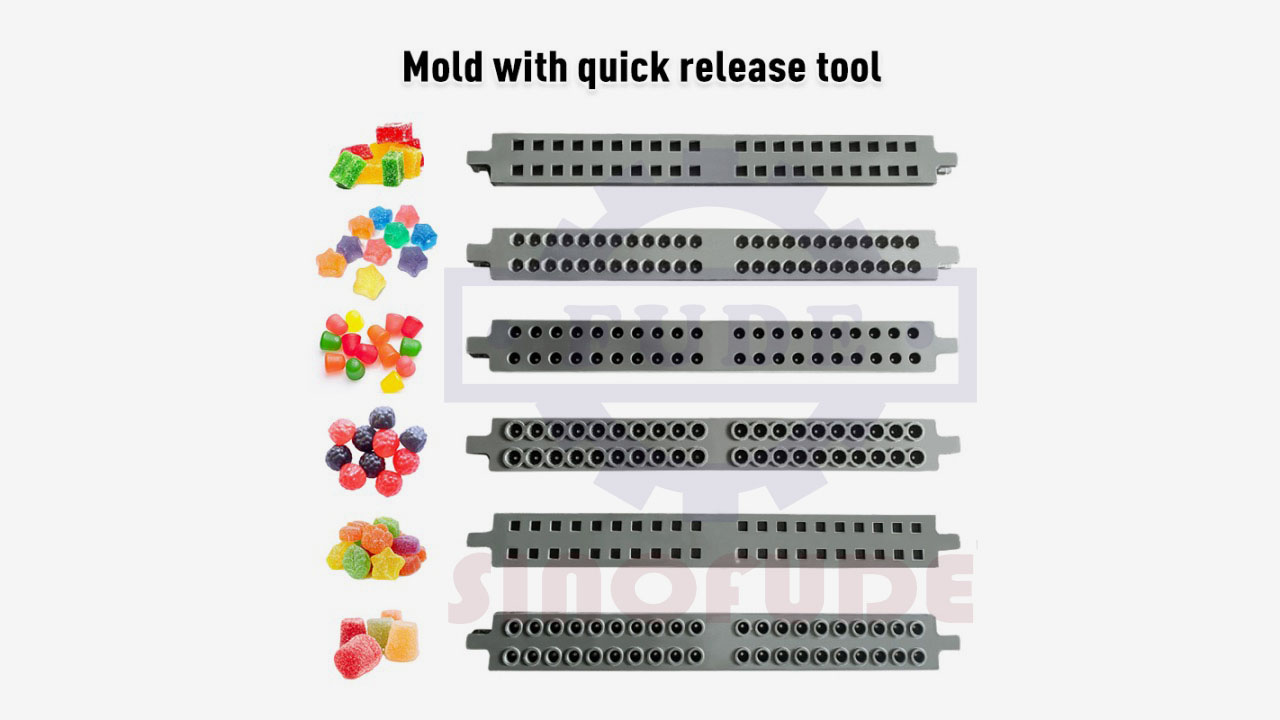

The mold can be made of Teflon coating or silicone, and has an ejection pin design that is easy to fall off. Molds of different shapes can be made according to customer needs.

As a world-class candy production line manufacturer, Shanghai Fuda can perfectly provide the production lines and production suggestions required for gummy production. If you have any needs, you can visit our gummy production line website to get the latest product consultation and complete solutions.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.