Makina opangira maswiti olimba ndi makina opangira maswiti olimba, omwe amaphatikizapo masitepe monga kusakaniza shuga, kuwiritsa shuga, kuziziritsa, kupondaponda, ndi kupakira. Mapangidwe ndi masanjidwe a mzere wopangawu nthawi zambiri amasinthidwa malinga ndi zosowa zopanga, zomwe zimatha kukwaniritsa masikelo osiyanasiyana.

Mzere wopangira maswiti olimba ndi zida zamagetsi zomwe zimagwiritsidwa ntchito popanga maswiti olimba, omwe amaphatikizanso masitepe monga kusakaniza shuga, kuwira shuga, kuziziritsa, kupondaponda, ndi kuyika. Mapangidwe ndi masanjidwe a mzere wopangawu nthawi zambiri amasinthidwa malinga ndi zosowa zopanga, zomwe zimatha kukwaniritsa masikelo osiyanasiyana.

Mayendedwe a ntchito:

1. Kusakaniza shuga: Sakanizani zipangizo zosiyanasiyana (monga shuga, shuga, madzi, ndi zina) kuti mupange madzi.

2. Kuwira shuga: Kutenthetsa madzi osakaniza mpaka kutentha kwina kuti afikire shuga woyenerera kupanga shuga wolimba.

3. Kuziziritsa: Madzi otentha amayenera kuziziritsidwa kuti apange maswiti olimba oyenera kupanga.

4. Kupanga: Madzi ozizira amadyetsedwa mu makina okhomerera ndipo mawonekedwe ake amasindikizidwa mu maswiti olimba kupyolera mu nkhungu yapadera.

5. Kupaka: Maswiti opangidwa mwamphamvu akakhazikika ndikukhazikika, amapakidwa pogwiritsa ntchito makina opangira okha.

Mbali Zazikulu za SINOFUDE Fully Automatic Die Hard Sugar Production Line:

1. Kuchita bwino kwambiri: Mzerewu umatha kupanga madzi owiritsa mwachangu ndikugwira ntchito mosalekeza kwa maola 24.

2. Kuwongolera khalidwe: Mwa kuwongolera molondola magawo a sitepe iliyonse, ubwino ndi kukoma kwa maswiti olimba zikhoza kutsimikiziridwa.

3. Mlingo wapamwamba wodzipangira okha: Njira yonse kuchokera ku zopangira zosakaniza mpaka kupanga shuga wovuta, mpaka kulongedza, zitha kukhala zokha, kuchepetsa kwambiri kulowererapo pamanja, kuwongolera magwiridwe antchito komanso mtundu wazinthu.

4. Kusiyanasiyana: Posintha zisankho zosiyanasiyana, mawonekedwe osiyanasiyana ndi makulidwe a maswiti olimba amatha kupangidwa kuti akwaniritse zofuna za msika.

Parameter:

1-Auto Weighting and mixing system

Kufotokozera kwa makina oyezera ndi kusakaniza:

Zipangizo zakukhitchini zimapereka zochulukirapo kuposa kuyeza kodziwikiratu komanso kusakanikirana kwazinthu zopangira ndi zoyendera zoyendera kupita kugawo limodzi kapena zingapo zopanga. Zimapanganso maziko a kupanga kosalekeza. Ndi auto-zosakaniza masekeli dongosolo processing wa makampani confectionery. Shuga ndi zopangira zonse zimangoyezera kulemera ndi kusakaniza. Mechanical balance, PLC yoyendetsedwa. Matanki osakaniza amalumikizidwa kudzera mu dongosolo lolamulidwa ndi PLC ndi kukumbukira. Chinsinsicho chimakonzedwa ndipo zosakaniza zimayesedwa moyenera kuti zipitirire kulowa mu chotengera chosakaniza. Zosakaniza zonse zikadyetsedwa muchombo, pambuyo pa kusakaniza, misayo idzasamutsidwa ku zipangizo zopangira. Maphikidwe ambiri a maswiti amatha kukhazikitsidwa pamtima momwe mukufunira.

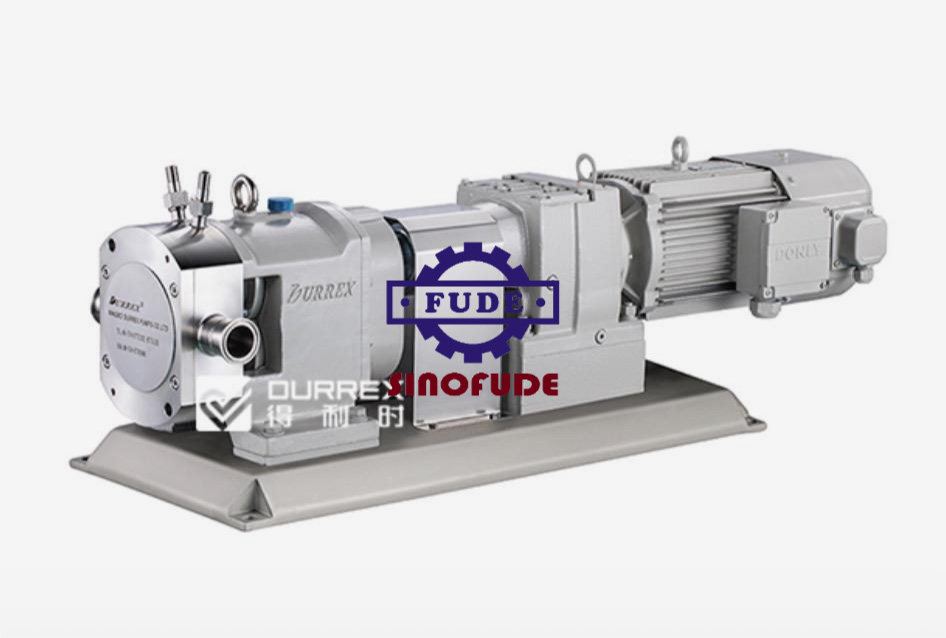

2 - Pampu yamadzi

Kufotokozera kwa pampu ya gear:

Pampu ya lobe iyi imagwiritsidwa ntchito kusamutsa zinthu zosungunuka ku thanki yosungira.

Oyenera mwapadera kuperekera madzi ku thanki yosungiramo kapena cooker.

3-Thanki yosungira

Kufotokozera kwa tanki yosungira:

Tanki yosungirako imagwiritsidwa ntchito posungira zinthu zomwe zasungunuka; choyambitsanso chimakhala ndi thanki ndipo chimapangitsa madziwo kuti azikhala mkati mokhazikika.

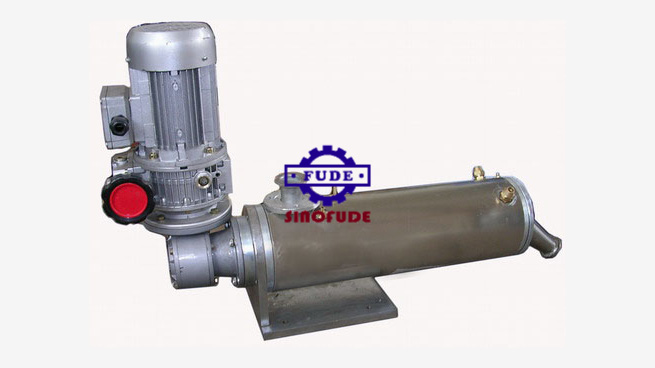

4 - Chophika chofufumitsa

Kufotokozera kwa vacuum cooking system:

Chophika chophikira chodziwikiratu ichi ndi chida chabwino chophikira maswiti owiritsa, chimaphika mosalekeza ndikukonza vacuum, ndi chophikira kale chophikira maswiti olimba m'malo mwa batch vacuum cooker.

1. The processing wa dongosolo ndi kuphika mosalekeza ndi vacuum zotsatira.

2. Kusinthana koyenera kwa kutentha, kumapangitsa kuphika bwino komanso mofanana.

3. Kugwira ntchito kwapakati ndi kuwongolera kuchokera ku nduna, kumagwira ntchito mosavuta ndikusamalira.

4. Kutulutsa ndi pampu kapena kutulutsa kwaulere kulipo pokonza zosiyanasiyana.

Pampu yovumbulutsira madzi ndi chipinda chachikulu chimapangitsa kuwongolera bwino kwa chinyezi ndi kutentha kwa misa yomaliza yophika.

5-Colour flavor inline chosakanizira

Kufotokozera kwa inline mixer:

Chosakaniza ichi chapakati chikugwira ntchito limodzi ndi pampu yotulutsa. Mapangidwe amkati a chosakanizira amakhala ndi magawo atatu, kukankhira phula, mano ozungulira ndi kukonza mano. Mano ozungulira amakhazikika pa shaft yozungulira ndikuwongoleredwa ndi mota yosinthika.

Kudyetsa mtundu, kukoma ndi asidi kapena gelatin yamadzimadzi imapezeka pamapaipi omwe ali pamwamba pa phula lopopera.

6-Colour flavor hold and dosing system

Kufotokozera za mtundu ndi kakomedwe kagwiridwe ndi dosing dongosolo:

Mtundu, kakomedwe kake ndi kachitidwe ka dosing kamakhala ndi mtundu wamadzimadzi komanso kukoma kosungira thanki, pampu ya dosing, mapaipi ndi chithandizo cha chimango.

Kukula kwa thanki ndi pampu ya dosing kumadalira mphamvu ya dosing system, 10L ~ 100L ya thanki ilipo ndipo mphamvu ya mpope ya dosing imatha kusintha pamanja kapena kuchokera ku PLC.& HMI. Pampu ya dosing itha kusankhidwa ndi LMI ya mtundu waku USA kapena RDOSE ya mtundu wa GERMANY.

7-Kuzizira conveyor

Kufotokozera kwa lamba wozirala:

Dongosolo loziziritsa lalikululi lili ndi lamba wozizirira wachitsulo chosapanga dzimbiri wokhala ndi makina otenthetsera madzi.

Lamba woziziritsa ndi lamba wachitsulo chosapanga dzimbiri wochokera ku SANVIK, yemwe amadziwika padziko lonse lapansi kupanga lamba wachitsulo chosapanga dzimbiri, lamba wosapindika komanso wozizira bwino. Lambawo umakhazikika popopera madzi ozizira pansi pa lamba.

Kutentha komaliza kwa misa kumadalira kuthamanga kwa ng'oma ndi lamba ndi kutentha kwa madzi ozizira.

8-Kutumiza conveyor

Kufotokozera kwa makina otumizira:

Makina otumizira amakhala ndi magawo awiri omwe ndi chakudya cha hopper ndi lamba wonyamula. Liwiro lamayendedwe limasinthika.

9-Batch roller

Kufotokozera kwa batch roller:

Chidachi chimagwiritsidwa ntchito makamaka pakugudubuza maswiti olimba kapena maswiti otafuna, amakhala ndi bokosi lamagudumu, zodzigudubuza zisanu ndi chimodzi, riser, bokosi lowongolera, ndi zina zambiri. Zimagwira ntchito ndi sizer ya chingwe kapena makina odzaza chapakati kuti apange maswiti odzaza pakati.

10-Chingwe kukula

Kufotokozera za kukula kwa chingwe:

Chida ichi chimagwiritsidwa ntchito kwambiri popanga maswiti olimba kapena maswiti a chewy, amakhala ndi gudumu lopanga ndi bokosi lowongolera. Amagwiritsidwa ntchito popanga chubu cha confection. Zimagwira ntchito ndi batch roller, extruder, kupanga makina etc.

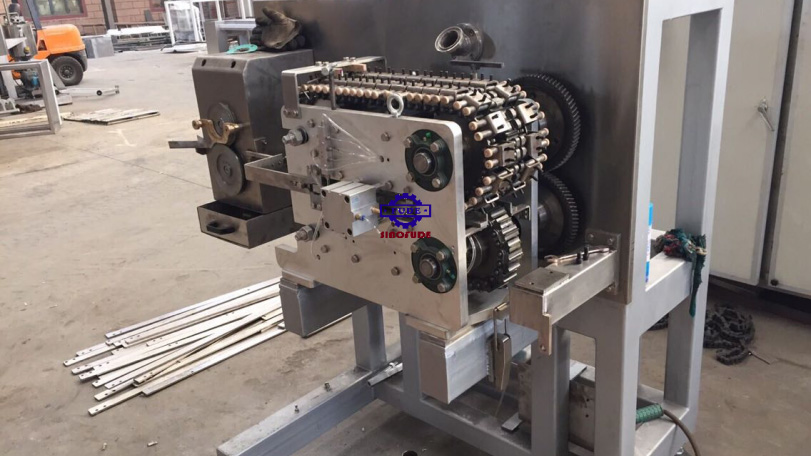

11-High Speed Chain kupanga makina

Kufotokozera kwa makina opangira maswiti olimba:

Makina opangira kufa awa ndi mtundu wa unyolo, amapangidwa mtundu womwe umakhala ndi mawonekedwe abwinoko, mawonekedwe abwinoko komanso kuwonongeka kochepa komwe kulipo.

1. Zopangidwa kutengera luso laukadaulo lakunja komanso njira yopangira mkati.

2. Zida za m'badwo watsopano zomwe zili zapadera kwa maswiti olimba opangidwa ndi kufa.

3. Angathe kupanga mitundu yosiyanasiyana ya maswiti olimba, maswiti a zipatso ndi maswiti okhala ndi jamu kapena ufa pakati, ndi njira yofunidwa ndi makasitomala kuti apange maswiti olimba posintha nkhungu zamaswiti.

12-Swing discharger

13-Kuzirala

Kuzizira kwa ngalandeyo kutalika: 6meter, Utali wonse: 7meter

Kusintha liwiro inverter: 0 ~ 6m/mphindi, Kufala mphamvu: 4kw

Firiji: 10 firiji, Madzi ozizira nsanja

Lamba wa pulasitiki kapena wiremesh: zigawo zitatu, lamba wa Conveyor m'lifupi: 1000mm

Ubwino wamakina:

Makasitomala mufakitale yathu

Makina mufakitale yathu

Lumikizanani Nafe

Ingosiyani imelo kapena nambala yanu yafoni pa fomu yolumikizirana kuti tikupatseni ntchito zambiri! funsani fomu kuti tikupatseni ntchito zambiri!

Onse amapangidwa motsatira mfundo zokhwima zapadziko lonse lapansi. Zogulitsa zathu zalandira chiyanjo kuchokera kumisika yapakhomo ndi yakunja.

Tsopano akutumiza kwambiri kumayiko 200.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Ufulu Onse Ndiotetezedwa.