— Leveraging CLM's fully automated gummy candy casting production line, we help our clients enter the high-margin sports nutrition gummy candy market.

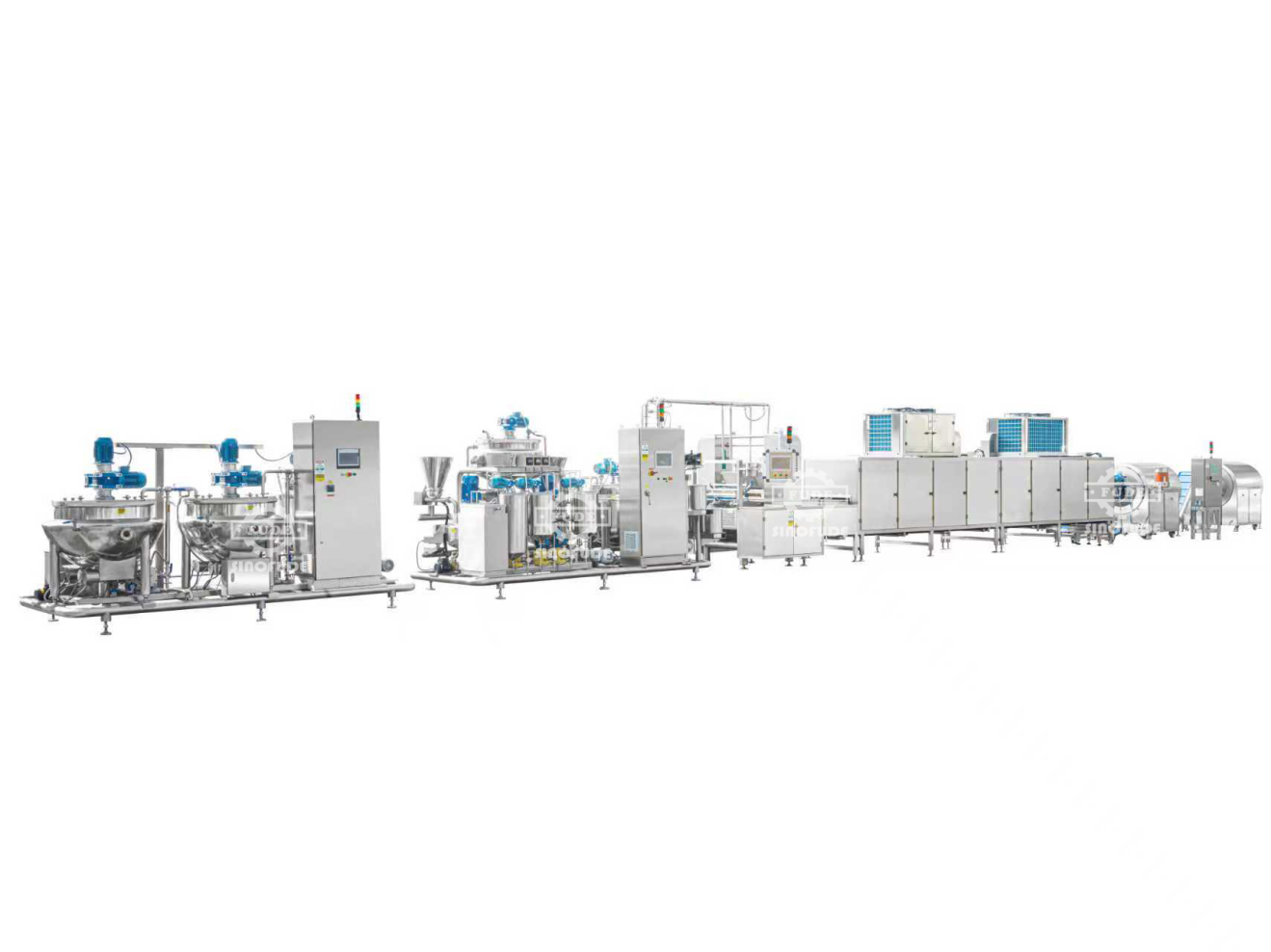

[Shanghai, December 2025] — With the explosive growth of the global functional gummy candy market, the pharmaceutical and health supplement industries have placed near-stringent demands on the cleanliness of the production environment and dosage control. As a leading company in the food and pharmaceutical machinery sector, Shanghai SINOFUDE Machinery Manufacturing Co., Ltd. officially launched its flagship model—the CLM600 fully automated gummy candy casting production line—which completely revolutionizes traditional production methods with its leading starchless process.

Technological Innovation: Why is "Powder-Free Mold" the Future of Functional Gummies?

Traditional starch molding (Mogul) production lines have long suffered from drawbacks such as dust pollution, cross-contamination, and long production cycles (requiring 24 hours of drying). SINOFUDE CLM600 employs an advanced powder-free molding process :

Ultimate hygiene: The aluminum mold is coated with Teflon, completely eliminating starch dust and meeting the stringent standards of GMP and FDA .

High-efficiency production: Compared with traditional processes, the CLM600 achieves continuous operation from raw material cooking to finished product demolding, significantly shortening the production cycle.

Space and manpower savings: The compact structural design and high integration save enterprises a significant amount of factory space and operating personnel.

Key Specifications: The CLM600's Outstanding Performance

The CLM600 model not only boasts a robust production capacity of 600 kg/h , but also integrates several cutting-edge technologies:

Fully automated PLC and servo drive: A complete servo system enables precise depositing, minimizing errors in the active ingredients of each gummy and ensuring consistent dosage.

Intelligent weighing and dispensing: Paired with the CCL series automatic weighing and dispensing system, it ensures absolute accuracy in formula execution.

One-click CIP cleaning: Integrates CIP in-situ cleaning function, which can complete deep cleaning of the entire line without disassembling the pipeline, greatly improving production efficiency.

Versatile casting modes: Whether it's **single color, two colors, left and right two colors, or center-filled** gummy candies, you can easily achieve it by simply changing the module.

Pharmaceutical companies' top choice: Real-world proven reliability

Currently, the CLM600 has been successfully applied by many well-known domestic and international pharmaceutical and nutritional supplement companies for the production of functional gummies containing active ingredients such as vitamins, minerals, and CBD . Its accompanying cooling tunnel features variable frequency cooling and efficient dehumidification , ensuring the gummies maintain perfect taste and appearance stability during demolding.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.