Uniform Texture, Stable Softness—Tailored for Confectionery Brands & Snack Markets

Shanghai | SINOFUDE — A turnkey process covering Ingredient Preparation & Cooking → Inflating & Molding → Cooling & Setting → Cutting & Sorting → Weighing & Packaging → Metal Detection, designed for confectionery brands, snack OEMs, supermarket private labels, and cross-border e-commerce candy production, focusing on high-quality marshmallows with consistent softness and delicate texture.

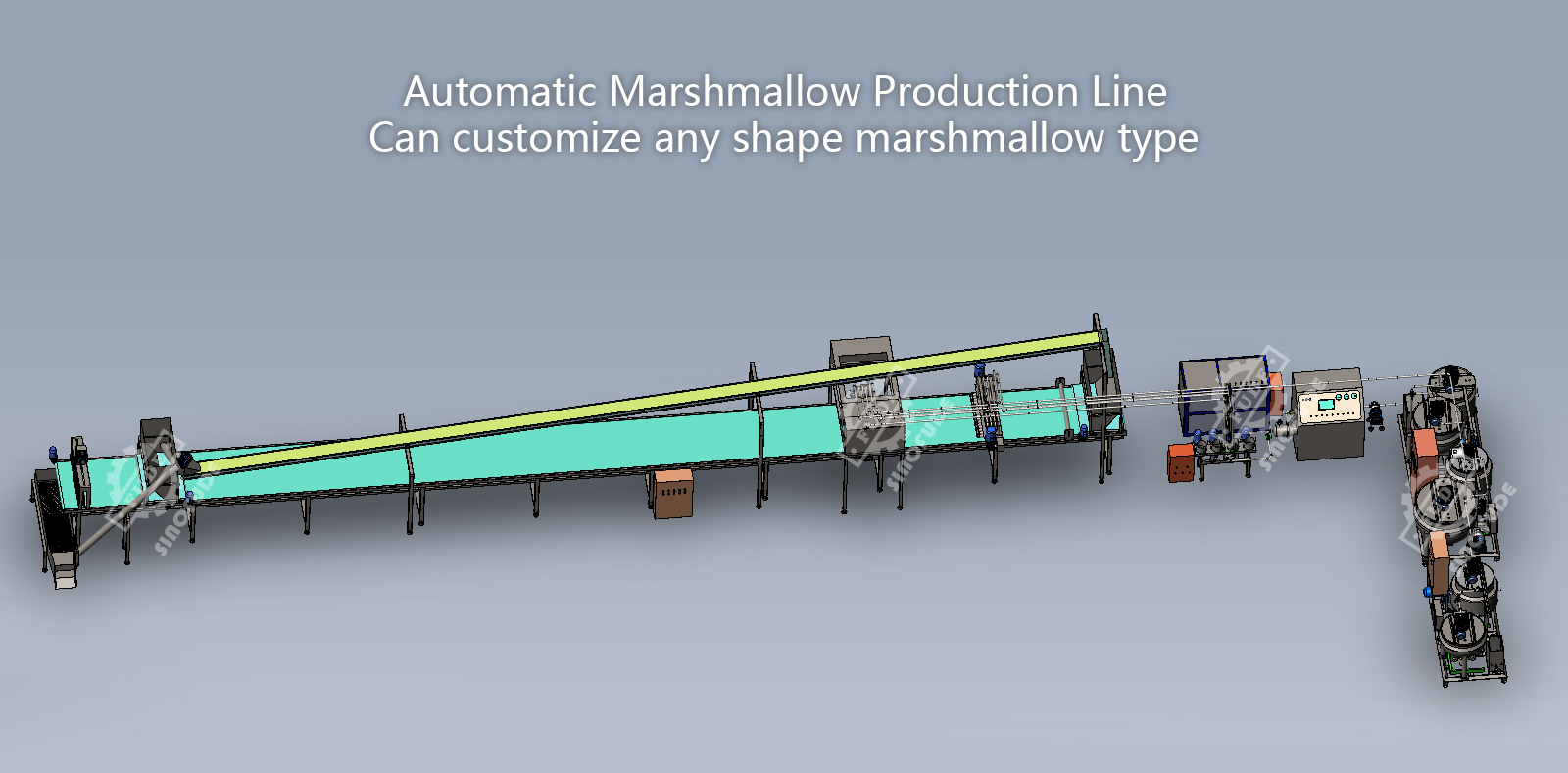

Production line display

Four Core Modules

· 1) Ingredient Preparation & Cooking System

· Purpose: Precisely proportion sugar, gelatin, syrup, food coloring, and flavors; control cooking temperature and viscosity to achieve uniform emulsification, laying the foundation for smooth whipping.

· Key Features: High-precision metering and feeding devices (error ≤ ±0.5% for main ingredients like sugar/syrup) supporting simultaneous multi-ingredient feeding; double-jacketed cooking pot with real-time temperature monitoring (105-120℃ adjustable) to prevent scorching; integrated homogenizer to enhance ingredient fineness and avoid granularity; optional raw material premix tanks (linked with main cooking pot) to reduce batch variation and improve product stability.

· 2) Inflating & Molding System

· Method: Cooked ingredients are transferred to a vacuum whipping machine (controls whipping density and air content) → Continuous extrusion molding (servo-driven to ensure uniform flow) → Custom molds (supports round, strip, cartoon-shaped, and filled marshmallow designs) → Low-temperature setting zone.

· Performance: Molding accuracy: single marshmallow weight error ≤ ±1.2% (size customizable from 10-50mm); texture consistency: whipped density uniformity ≥ 97% (no hollow or lumpy defects); adaptive adjustment of whipping parameters (real-time adjustment based on ingredient viscosity) to maintain stable softness and elasticity; filled marshmallow option: built-in flavor injection module for dual-texture products.

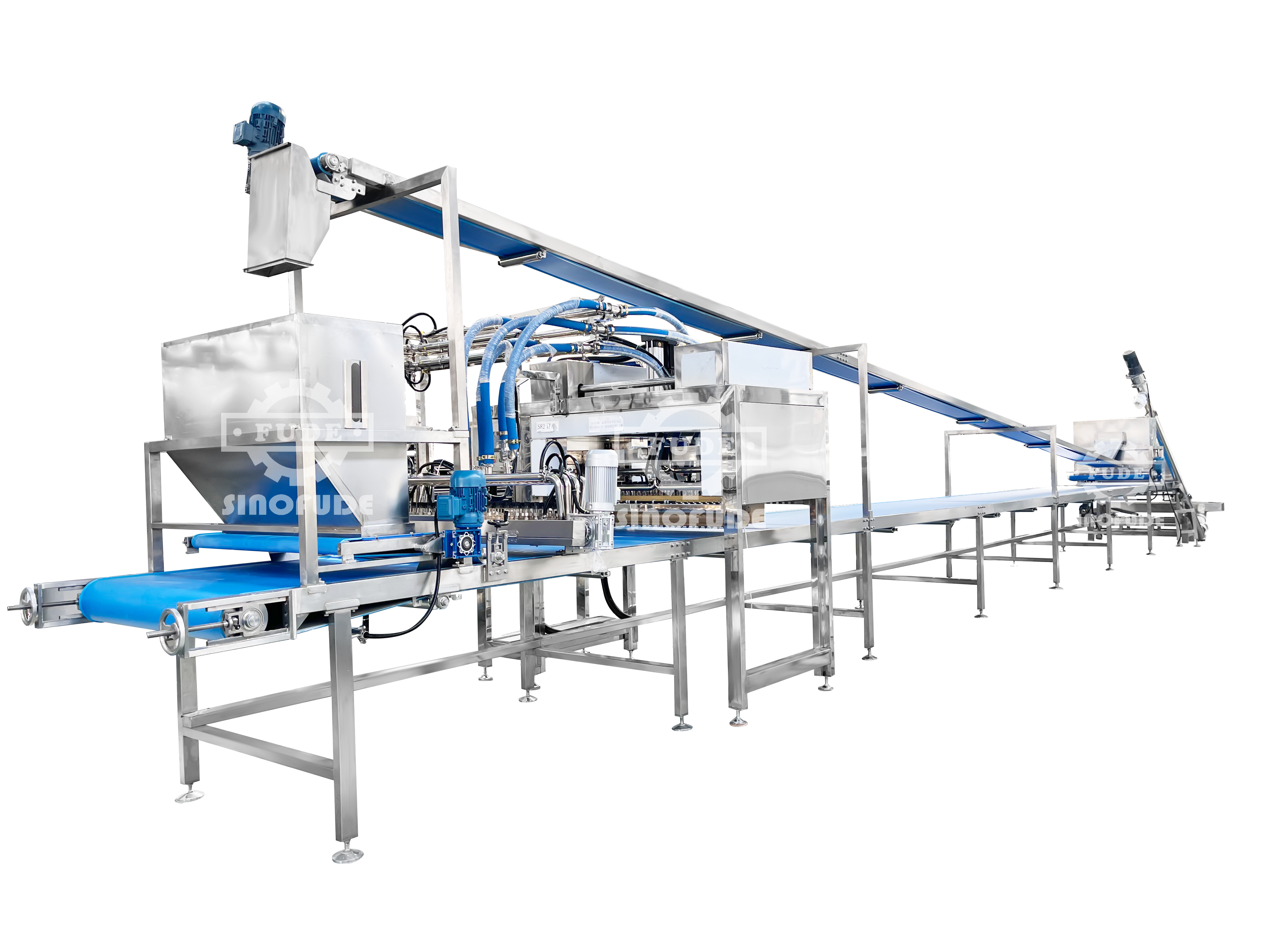

Cooking and Inflating system

Process flow chart display

3) Cooling & Setting System

· Flow: Molded marshmallows are conveyed to a low-temperature tunnel via food-grade anti-stick conveyor → Gradient cooling (from 15℃ to 8℃) → Static setting zone → Stabilize texture and prevent deformation.

· Cooling Control: 3-zone temperature-adjustable cooling tunnel (pre-cooling: 12-15℃, core cooling: 8-10℃, setting: 10-12℃); synchronized conveyor speed adjustment to match different marshmallow formulas.

· Setting Effect: Marshmallow center temperature after cooling ≤ 12℃ to ensure firm shape without collapse; anti-stick conveyor belt (food-grade silicone material) to avoid product adhesion; optional energy-saving insulation layer to reduce cold loss.

Molding and cooling system

4) Cutting, Sorting & Packaging & Inspection System

· Flow: Cooled marshmallows pass through a high-precision cutter (customizable cutting size) → Vibrating sorter (removes crumbs and deformed products) → Food-grade conveyor → Multihead weigher for precise dosing → Automatic packaging machine for sealing → Nitrogen filling (optional) → Metal detector (removes products with metal impurities).

· Packaging Specifications: Supports individual sachets (5-30g/sachet), boxed packaging (with inner individual sachets), and industrial buckets (1-5kg/bucket).

· Freshness Design: Optional nitrogen-filled packaging to extend shelf life to 8-12 months while preserving soft texture; quality control: metal detection accuracy (Fe ≥ 0.8mm, SUS ≥ 1.5mm) meeting food safety standards; optional packaging seal tester to prevent moisture absorption.

Product display

Key Specs & Materials

· Throughput: 60-500 kg/h (adjustable based on marshmallow size and formula; customized capacity available)

· Hygienic Design: SUS316 stainless steel for product-contact parts, SUS304 stainless steel for frames and enclosures; food-grade silicone/PU for conveyors and molds; quick-release structure for easy disassembly and cleaning to eliminate hygiene dead corners

· Controls: PLC + HMI (Siemens/Omron) with one-touch recipe retrieval (supports storage of 50+ marshmallow process parameters); full-process batch traceability (raw material input, cooking temperature, whipping time, packaging time, etc., accessible)

· Options: Inline density detector (real-time monitoring of marshmallow texture), automatic mold change device, UV sterilization module, remote maintenance and data monitoring platform, filled marshmallow flavor injection system

Use Cases

Confectionery chain brands (in-house factory production), snack food OEM co-packers, supermarket private label customization, cross-border e-commerce candy production, and campus/cinema/scenic spot catering marshmallow suppliers.

Quote: “The 'uniform texture' and 'stable softness' of marshmallows are core customer demands, and we designed the line to balance 'production efficiency' and 'product quality'. Through collaborative optimization of precise cooking, vacuum whipping, and intelligent sorting, customers can not only continuously produce marshmallows with delicate taste and neat appearance, but also control raw material loss within 4% and reduce equipment downtime for cleaning by 25%.” —— SINOFUDE Product Manager

About SINOFUDE / Media Contact

SINOFUDE delivers end-to-end solutions for confectionery, bakery (including crispy biscuits), chocolate, and popping boba equipment—from lab-scale trials to full production lines.

Email: info@sinofude.com | Shanghai, China

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.