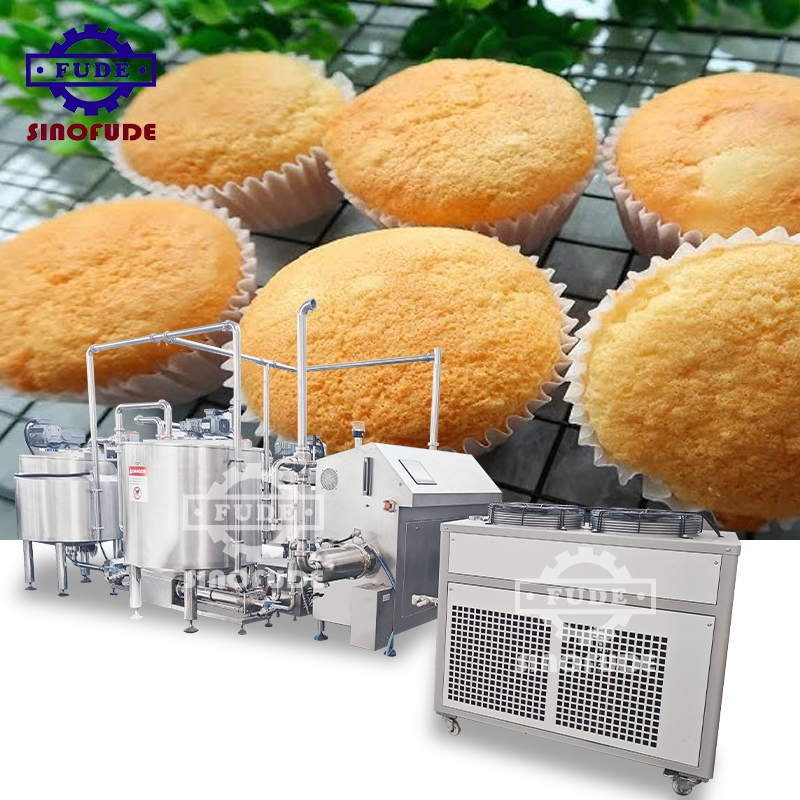

The cupcake production line is a complete baking equipment system, including several key links.

The cupcake production line is a complete baking equipment system, including several key links. First, the raw materials are accurately weighed and then enter the mixer to be fully mixed into a uniform batter. The batter is whipped by the whisk until it is fluffy and poured into the paper cups. The paper cups are usually placed on the baking tray by an automatic cup dispenser and then put into the oven for baking. After baking, the cooling conveyor belt sends the cake to the decoration area for decoration such as cream decoration and powdered sugar. Finally, the finished product is sealed and packaged by the packaging machine to complete the production. The whole process is highly automated and efficient, which can ensure the quality and taste of the cupcakes.

Cupcakes can be classified into many categories based on flavor, decoration, purpose, etc. Here are some common product types: chocolate cupcakes, vanilla cupcakes, strawberry cupcakes, cream decorated cupcakes, and nut cupcakes.

| Key Selling Points | Multifunctional | warranty | 1 Year |

| condition | New | power(w) | customized |

| dimension(l*w*h) | customized | place of origin | place of origin |

| Automatic Grade | Optional | voltage | 220V 380V 50HZ customized |

| Final product | chocolate cupcakes, vanilla cupcakes, strawberry cupcakes, cream decorated cupcakes, and nut cupcakes | Name | cake production line |

| Shape | Customrized | Application | Cake Bakery Machine |

| Material | Food Grade Stainless Steel | Function | Multifunctional |

| Machinery Test Report | Provided | Core Components | motor |

The cream beater plays a key role in the cupcake production line. It can quickly whip ingredients such as eggs and cream, fully mix the ingredients and produce rich bubbles, so that the cupcakes expand in volume and have a soft texture. The whipping effect directly affects the taste and quality of the cake, and is an important equipment to ensure the production quality of cupcakes. The equipment is equipped with a food-grade rotor pump to maximize the preservation of raw material characteristics, support a maximum conveying distance of 12 meters, and effectively separate the whipping area from the production area, making the product texture more delicate and stable, the color more uniform, the taste better, and the shelf life longer.

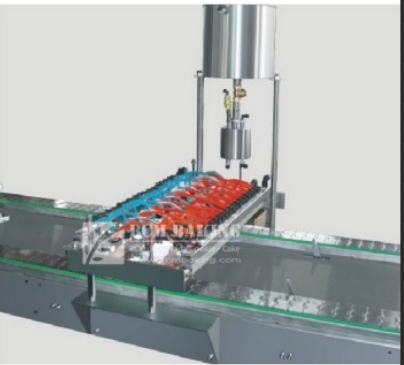

The cupcake sucker plays a key role in the cupcake production line. It can accurately grab and transfer cakes to avoid contamination or damage caused by manual contact. Through the adsorption force of the sucker, the cake can be stably handled, the production efficiency can be improved, and the integrity and hygiene of the cake during packaging or transportation can be ensured. It is an indispensable automation equipment for cupcake production.

The cupcake placing machine plays a vital role in the cupcake production line. It can quickly and accurately place cakes into paper cups, greatly improving production efficiency and reducing the tediousness and errors of manual operation. At the same time, its automated operation ensures the uniformity and consistency of cake placement, ensures stable product quality, and provides strong guarantee for the subsequent packaging and sales of cupcakes.

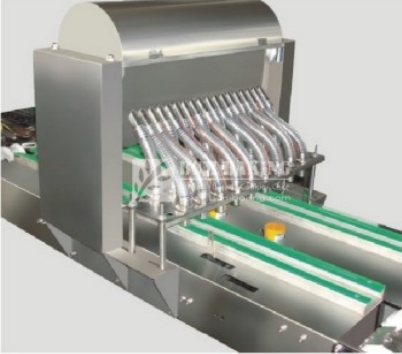

The oil sprayer is used in the cupcake production line to evenly spray edible oil on the inner wall of the paper cup. It can prevent the cake batter from adhering to the paper cup, ensure the cake is completely demoulded after baking, and maintain its beautiful shape. At the same time, the automatic operation of the oil sprayer saves labor, improves production efficiency, ensures uniform oil content, and improves product quality stability. It is an indispensable equipment for cupcake production

The nut spreader is used in the cupcake production line to evenly spread the nuts on the surface of the cake. It can accurately control the amount and distribution of the nuts, ensuring that the nuts of each cupcake are evenly distributed, improving the taste and appearance of the product. Automated operation improves production efficiency, reduces manual operation errors, ensures consistency of product quality, and adds a unique flavor to the cupcake.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.