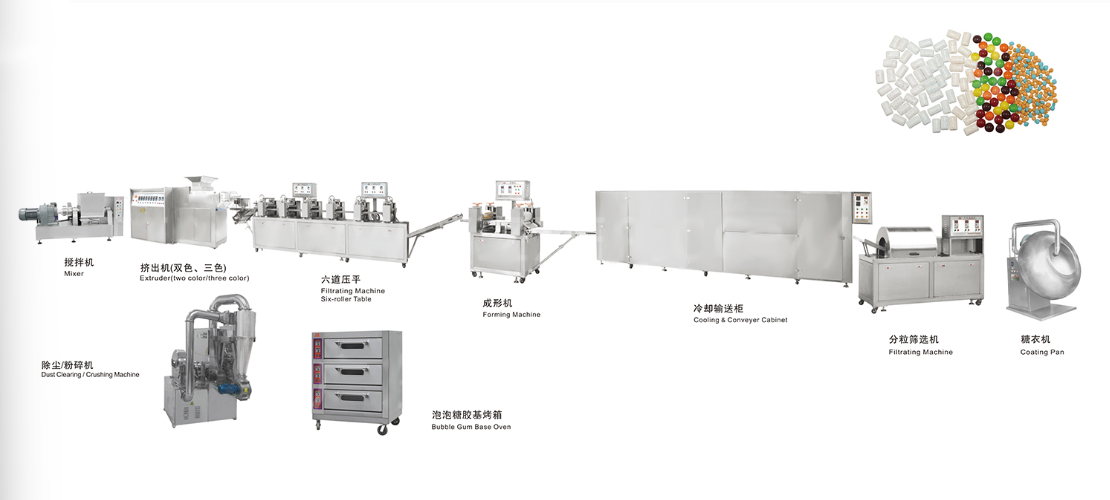

The chewing gum production line is a fully automated manufacturing system comprising several critical stages. First, raw materials such as gum base, sweeteners, and flavors are precisely weighed and fed into high-shear mixers to form a homogeneous blend. The mixture is then transferred to extruders, where it is kneaded and shaped into sheets or ropes under controlled temperature and pressure.

The chewing gum production line is a fully automated manufacturing system comprising several critical stages. First, raw materials such as gum base, sweeteners, and flavors are precisely weighed and fed into high-shear mixers to form a homogeneous blend. The mixture is then transferred to extruders, where it is kneaded and shaped into sheets or ropes under controlled temperature and pressure.

Next, the gum passes through molding equipment, where it is stamped into sticks, pellets, or other desired shapes using precision-cut dies. For coated varieties, the pieces enter a rotating drum or spray chamber to receive a uniform sugar or polyol coating. After coating, the gum is rapidly cooled in a chilling tunnel to stabilize its texture.

Finally, the finished products are conveyed to packaging machines, where they are wrapped in foil, blister packs, or bottles with airtight seals to preserve freshness. The entire process is streamlined for maximum efficiency and hygiene, ensuring consistent flavor, texture, and quality in every piece of chewing gum. Advanced sensors and automated controls maintain strict compliance with food safety standards throughout production.

Cupcakes can be classified into many categories based on flavor, decoration, purpose, etc. Here are some common product types: chocolate cupcakes, vanilla cupcakes, strawberry cupcakes, cream decorated cupcakes, and nut cupcakes.

| Classification | Sugar-Coated Chewing Gum | Bubble Gum | Chewing Gum |

| Structural Features | Gum core + sugar coating | High elastic gum base | Single layer/multi-layer tableting |

| Production Process | Fluidized bed coating or syrup dipping | High pressure extrusion molding | Roll cutting or die forming |

| Gum Base Content | 15-20% | 25-35% | 18-22% |

| Brix | Outer layer sugar content ≥80% | Total sugar content 40-60% | Total sugar content 50-70% |

| Representative Products | Mentos Cube | Big bubble gum | Green Arrow Mint Sticks |

| Packaging Form | Mentos Cube | Individual tin foil packaging | Aluminum foil strip packaging |

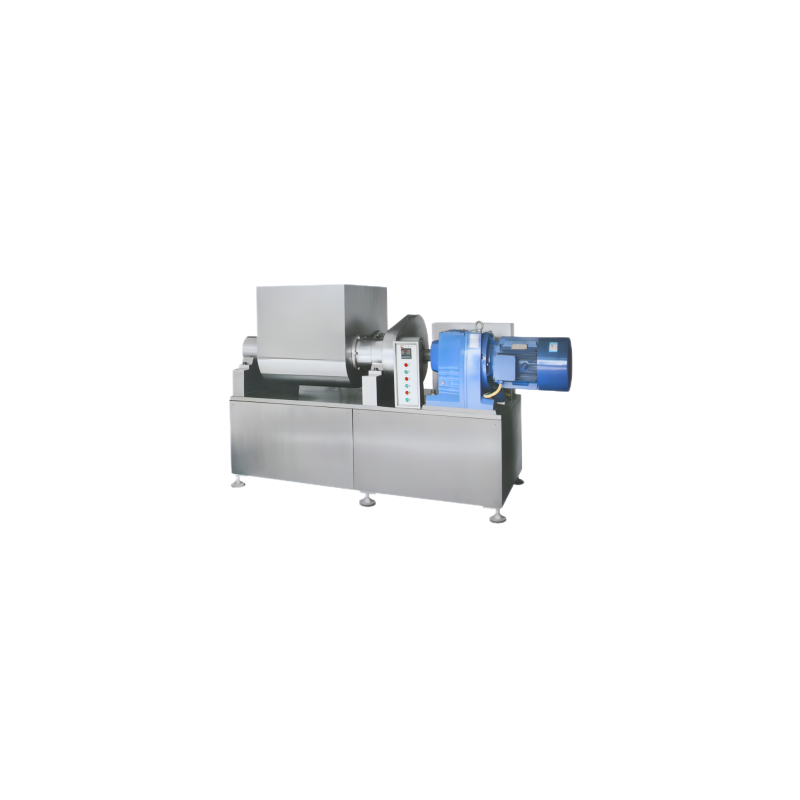

The This equipment is used for warming gum base by electricity.

(We could customize the heating way if you have other requirements)

It is made of isolation material and normal steels.

The heating element is controlled by a temperature controller.

The latest design based on the advanced technology.

It is widely used in the pharmaceutical, chemical, food and other industries

for the uniform mixing of different power or wet material.

Main performance:

Heating methods: includes steam heating and electricity heating.

Discharge methods: liquid pressure to tilt vat, lift the screw to discharge.

The candy extruder is suitable for a variety of products such as bubble and chewing gum, caramel, toffee, milk candy and Swiss candy.

The line allows to feed the factory candy extruder with cutting and packaging machine or the forming line for extruded products (such as chewy or chewing gum/bubble gum) in an automatic, continuous and uniform manner.

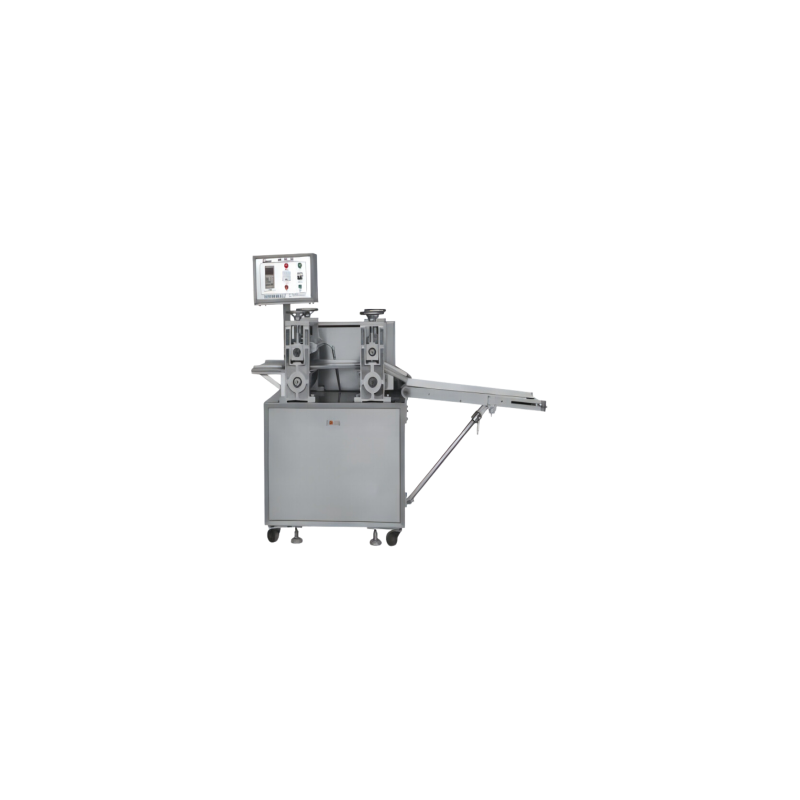

This machine is an essential production equipment for plate-shaped chewing gum and xylitol chewing gum. The sugar sheets coming out of the extruder are rolled and shaped by 6 pairs of shaping rollers.

Main features:

Each rolling roller is driven by a separate motor

Frequency conversion adjustment, cold water can be passed through the distance measuring roller

Upper powdering device

Bottom powdering device

Equipped with starch recovery device

Modular design, easy to clean and disassemble

Suitable for cutting xylitol chewing gum and plate-shaped chewing gum of various sizes

The cutter is made of high-speed steel, which is hard and non-sticky, making it the best choice for cutting gum materials.

The cutting speed is adjustable, and the gum length can be freely adjusted

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.