How to make pectin gummy candy with our pectin cooking system?

The gummy candy jacket cooker, and tank are all made of 3 layers, which can prevent burns.

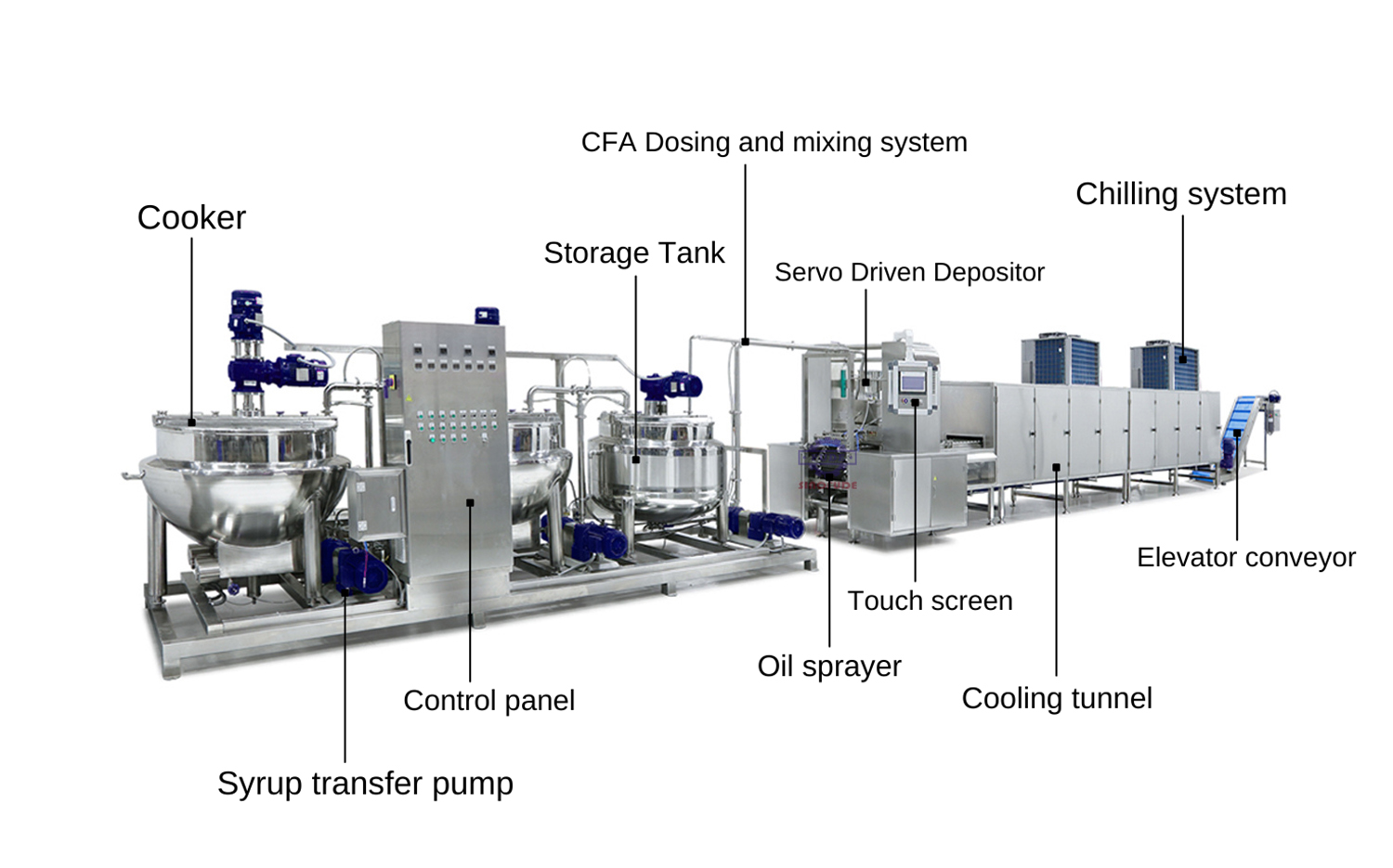

The first one is our jacket cooker for cooking the gummy candy raw materials. We need to pour the gummy candy raw materials into the jacket cooker-gummy candy machine, according to the recipe. The jacket cooker-gummy candy production machine, is equipped with Teflon scraping and stirring, equipped with a high-speed shear, which can fully dissolve the gummy candy raw materials. Pectin(gummy candy raw materials) is difficult to melt with water and it will clump together, so gummy candy machine of jacket cooker and tank function is very useful and friendly when you produce pectin gummy.

Generally speaking, the gummy candy cooking machine is good to boil it to 108 degrees. When the gummy candy syrup is cooked, we need to transfer the gummy candy syrup from the jacket cooker to the gummy candy syrup storage tank.

Which used to be gear pumps, but now uses lobe pumps. The lobe pump can be adjusted by frequency conversion. It will be more convenient for you to adjust the gummy candy syrup transport speed.

The main function of a gummy candy syrup storage tank is to buffer and ensure the flow of depositing.

Our gummy candy machine is equipped with two online mixing systems, static mixing, and dynamic mixing. For this kind of mixing system, After the gummy candy syrup is boiled, we use the mixing system for coloring and flavoring. In this way, the same batch of gummy candy raw materials can produce gummy candy of different colors or different flavors, which is more flexible and better for mixing flavors and colors and other ingredients. ( Most American gummy candy manufacture customers prefer to choose flavor, acids, vitamins, CBD, THC, and other functional ingredients )

The gummy candy production static mixing system is different from other manufacturers at a 90-degree angle. We inject the gmmy candy ingredients at a 45-degree angle so that the gummy candy ingredients and gummy candy syrup can be mixed more uniformly and stably. The gummy candy dynamic mixing: normally used plunger type quantitative pump.

Q&A:

1. What's the difference between pectin and gelatin of gummy candy raw material?

Most of our American gummy candy manufacture customers choose Pectin as raw material of gummy candy. Gelatin is mainly extracted from animals, and the taste will be more elastic. But gelatin of gummy candy raw material cannot withstand high temperatures, so we need an extra gummy candy of jacket cooker and storage tank to melt the gelatin.

2. What are the functional ingredients of gummy candy?

Functional gummies have become popular in recent years. Candy manufacturers prefer to add Vitamins, CBD, THC, and Melatonin into gummy candy. Like Melatonin gummy can help you to get a good night's sleep.

3. How do you make the Central filled or double-color gummy?

Our gummy candy machine of hoppers can be customized as double hoppers with two online dynamic mixing systems, which can help you produce Central filled or double-color gummy.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.