Popping Boba is a unique food item that originated in Taiwan. It is a type of boba, also known as bubble tea pearls or tapioca pearls, but with a delightful twist. Unlike traditional boba, Popping Boba is filled with flavored juice or syrup that bursts in your mouth when you bite into it.

Popping Boba is a unique food item that originated in Taiwan. It is a type of boba, also known as bubble tea pearls or tapioca pearls, but with a delightful twist. Unlike traditional boba, Popping Boba is filled with flavored juice or syrup that bursts in your mouth when you bite into it.

Popping Boba comes in various vibrant colors and flavors, such as strawberry, mango, lychee, passion fruit, and more. These small, translucent balls have a gelatinous texture on the outside and a burst of refreshing liquid on the inside. They add a playful and interactive element to beverages and desserts.

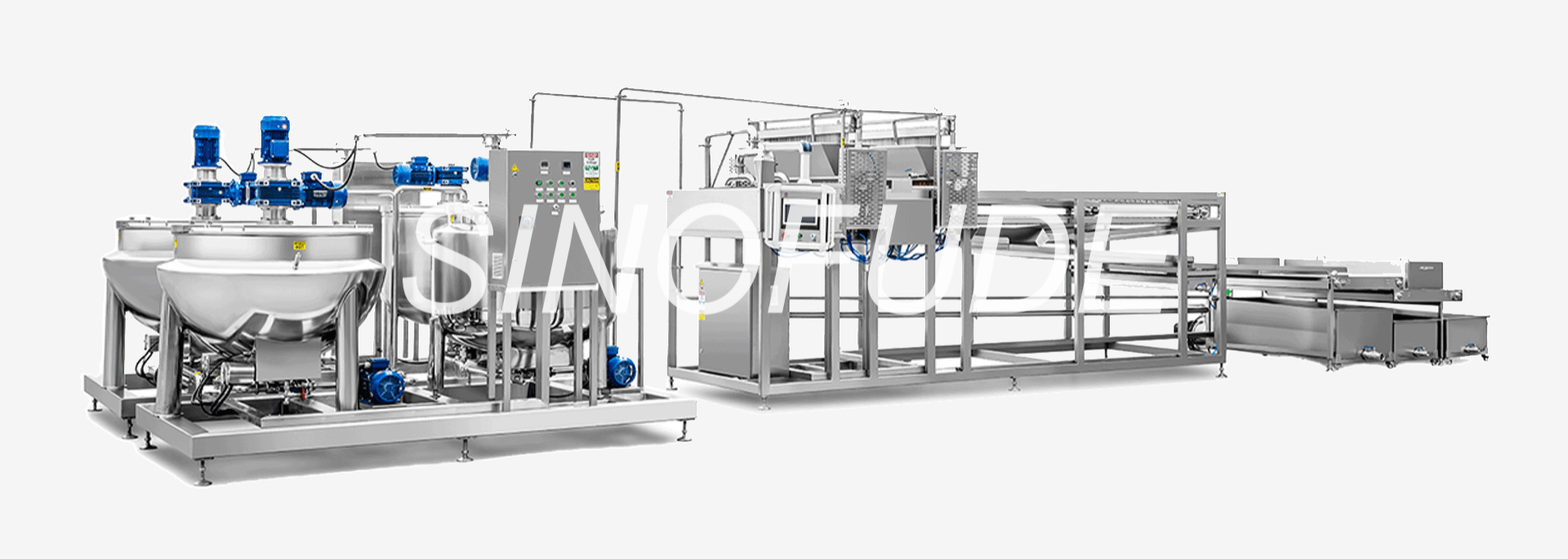

As the first manufacturer to produce a popping boba production line, Sinofude pioneered the industrial production of popping boba and set a standard for the industry. The popping boba production line is mainly divided into two parts, cooking and forming. And according to different capacity, it is divided into semi-automatic production line and fully automatic production line, which can meet different needs.

Work process:

1. Grinding sodium alginate: Mix sodium alginate and water in proportion and grind

2. Cooking the sodium alginate solution: Cook the ground sodium alginate and water according to the proportion

2.1. Cooking center-filled syrup: mix water, sugar, glucose syrup, calcium, flavors and colorss and other raw materials and cook

2.2 Cooking protection solution: mix water, sugar, syrup and other raw materials and cook

3. Cooling: Cool the center-filled syrup and sodium alginate solution

4. Forming: Depositing the center-filled syrup into the sodium alginate solution

5. Cleaning: Separate the formed boba from sodium alginate and clean it

6. Packaging: Fill boba and protective liquid according to the proportion

7. Sterilization: Put the packaged boba into a pasteurization machine for sterilization

Advantage:

1. Quality control: Ensure the quality and taste of popping boba by accurately controlling each process parameter.

2. High degree of automation: From raw material mixing to forming to packaging, the entire process can be automated, greatly reducing manual intervention and improving production efficiency and product quality.

3. Diversity: By replacing different nozzles or distribution plates, boba can be produced in different size ranges

Parameter:

1. Colloid mill

Colloid mill is an equipment for fine grinding of fluid and semi-fluid materials. Can be processed according to the requirements of the material, through the fixed teeth and rotating teeth high-speed operation, so that the material under the strong shear force.

This machine has superfine grinding, dispersing, emulsifying, homogenizing, mixing and other efficiency.It is widely used in Food industry, chemical industry, pharmaceutical industry, daily chemical industry, construction industry, paper industry, battery industry, etc.

Sodium alginate powder becomes wet with water, and the hydration of the particles makes the surface sticky. The particles then quickly stick together to form agglomerates, which are very slowly fully hydrated and dissolved. Therefore, the equipment is needed to assist the dissolution of sodium alginate in water and increase the dissolution rate.

2. Cooking system

The system is designed by SINOFUDE according to the processing technology of continuous popping boba making. The shell materials and filling materials are all needed to be cooked and cooled for forming, the color and flavor of filling will be added in the filling machine cooker after cooking.The stainless steel gear pump are installed also between the cooker and controlling for mass transferring. The cooled masses will be fed to the forming unit by a frequency inverter controlled gear pump as optional.

Other characters of Sinofude cooking system:

Jacket heating can be steam or electrical heating with thermal oil as optional

No sediments & over burned due to the Teflon scrapper fixed in stirrer

With steam to dissolve, rapidly, economic and convenient.

Mass cooking temperature is automatically controlled by good quality temperature controller.

Volume of kettles are customized according to different requirement.

3. CBZ series popping boba production line

CBZ popping boba production line was first developed by Fude Machinery in 2010 and is the largest manufacturer in China. It is easy to operate and has a high degree of automation. The whole machine is made of SUS304 material. High tech system has a compact struc-ture and high performance. Boba size can adjustable, the shape is full and round, and the color is beautiful. The capacity of this series is 50-500 kg per hour. It can also produce various products such as popping pearls and konjac boba, and artificial caviar.

Unmatched Quality: We prioritize the use of premium-grade ingredients to guarantee an explosion of flavor in every bite. Our production line maintains strict quality control measures, ensuring that each popping boba is uniformly-sized and bursting with delectable fruit juices.

Streamlined Efficiency: Our production line is engineered with advanced automation and intelligent controls, enabling seamless operations and maximizing productivity. Experience faster production cycles without compromising on the quality of your popping boba.

Customization Options: We understand that every bubble tea establishment has unique preferences. Our production line offers customizable settings, allowing you to adjust the size, color, and flavor of your popping boba to perfectly complement your signature beverages.

Hygienic Design: Maintaining a clean and sanitary production environment is vital. Our production line is designed with easy-to-clean materials and adheres to the highest hygiene standards, ensuring food safety and peace of mind for both you and your customers.

Technical Support: We believe in building long-lasting partnerships with our clients. Our dedicated team of experts is ready to provide comprehensive technical support, training, and troubleshooting assistance, ensuring a smooth integration of our popping boba production line into your business operations.

Contact us now to learn more about our popping boba production line and how it can give your bubble tea business a competitive edge. Don't miss out on this opportunity to create a memorable and unique experience for your customers.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.