Cov kab ua cov khoom qab zib nyuaj tuag yog cov cuab yeej siv ua haujlwm siab tshwj xeeb siv rau cov khoom qab zib nyuaj, uas feem ntau suav nrog cov kauj ruam xws li kev sib xyaw suab thaj, qab zib npau npau, txias, stamping, thiab ntim. Kev tsim thiab kev teeb tsa ntawm cov kab ntau lawm no feem ntau yog kho raws li kev xav tau ntau lawm, uas tuaj yeem ua tau raws li qhov sib txawv ntawm cov nplais.

Workflow:

1. Kev sib xyaw suab thaj: Sib tov ntau yam khoom siv raw (xws li qab zib, qabzib, dej, thiab lwm yam) ua ke los tsim cov kua qab zib.

2. Qab Zib boiling: Kub lub sib tov syrup mus rau ib tug tej yam kub kom ncav cuag ib tug qab zib cov ntsiab lus haum rau ua rau cov suab thaj nyuaj.

3. Ua kom txias: Cov rhuab syrup yuav tsum tau ua kom txias los ua ib qho khoom qab zib nyuaj kom haum rau kev sib sau.

4. Kev sib sau: Cov kua dej txias yog pub rau hauv lub tshuab xuas nrig ntaus thiab nws cov duab yog stamped rau hauv cov khoom qab zib nyuaj los ntawm cov pwm tshwj xeeb.

5. Ntim: Tom qab tsim cov khoom qab zib nyuaj yog txias thiab khov, nws tau ntim nrog lub tshuab ntim khoom siv tsis siv neeg.

Lub ntsiab nta ntawm SINOFUDE Siab Tsis Siv Neeg Tuag Hard Qab Zib Ntau Lawm Kab:

1. Kev ua haujlwm siab: Cov kab ntau lawm no tuaj yeem ua haujlwm sai sai thiab ua haujlwm tsis tu ncua rau 24 teev.

2. Kev tswj kom zoo: Los ntawm kev tswj xyuas qhov tsis zoo ntawm txhua kauj ruam, qhov zoo thiab saj ntawm cov khoom qab zib nyuaj tuaj yeem ua kom ntseeg tau.

3. High degree ntawm automation: Tag nrho cov txheej txheem los ntawm raw khoom sib tov rau cov suab thaj nyuaj, mus rau ntim, yuav ua tau automated, zoo heev txo cov kev cuam tshuam phau ntawv, kev txhim kho ntau lawm efficiency thiab cov khoom zoo.

4. Ntau haiv neeg: Los ntawm kev hloov pwm txawv, ntau yam duab thiab qhov ntau thiab tsawg ntawm cov khoom qab zib nyuaj tuaj yeem ua tau raws li kev xav tau ntawm kev lag luam.

Parameter:

1-Auto Weighing thiab mixing system

Nqe lus piav qhia ntawm nws pib qhov hnyav thiab sib xyaw ua ke:

Cov khoom siv hauv chav ua noj muaj ntau tshaj qhov tsis siv neeg qhov hnyav thiab sib xyaw ntawm cov khoom siv raw nrog inline thauj mus rau ib lossis ntau qhov ntau lawm. Nws kuj tsim lub hauv paus rau kev tsim khoom tas mus li. Nws yog ib qho khoom siv nws tus kheej qhov hnyav rau kev ua cov khoom noj khoom haus. Cov suab thaj thiab tag nrho cov khoom siv raw yog qhov tsis siv neeg qhov hnyav thiab kev sib xyaw ua ke. Mechanical tshuav nyiaj li cas, PLC tswj. Cov khoom xyaw tso tsheb hlau luam txuas nrog los ntawm PLC tswj qhov system nrog lub cim xeeb. Daim ntawv qhia yog programmed thiab cov khoom xyaw raug hnyav kom raug mus rau hauv lub nkoj sib tov. Thaum tag nrho cov khoom xyaw yog pub rau hauv lub nkoj, tom qab sib tov, qhov loj ces yuav raug xa mus rau hauv cov khoom siv. Ntau cov zaub mov txawv ntawm cov khoom qab zib tuaj yeem ua rau hauv lub cim xeeb raws li koj nyiam.

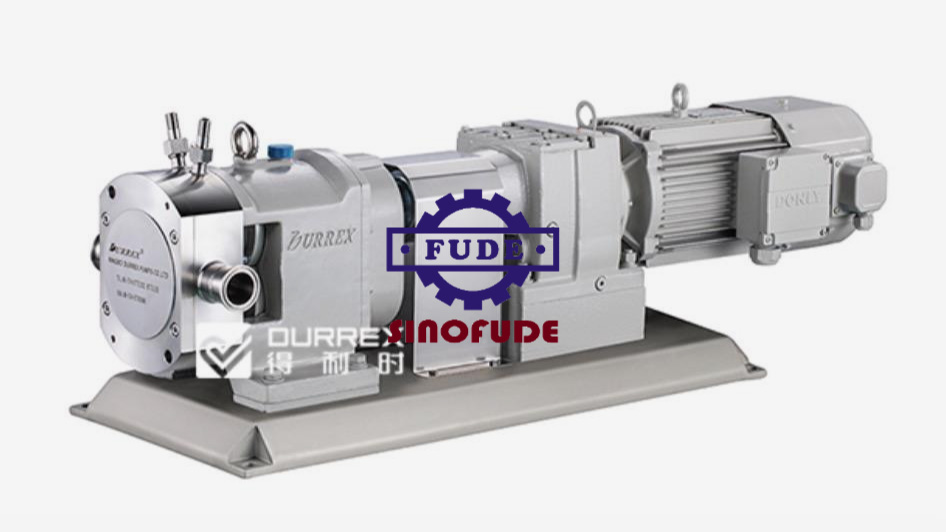

2-Lobe twj tso kua mis

Cov lus piav qhia ntawm lub iav twj tso kua mis:

Lub twj tso kua mis lobe no yog siv rau kev xa cov khoom siv yaj mus rau lub tank tuav.

Tshwj xeeb tshaj yog tsim nyog rau kev xa cov syrup mus rau lub tank cia lossis cooker.

3-Storage tank

Kev piav qhia ntawm lub tank cia:

Lub tank cia yog siv los tuav cov khoom siv yaj; lub stirrer yog nruab nyob rau hauv lub tank thiab ua rau cov kua qab nyob rau hauv khov kho tuav.

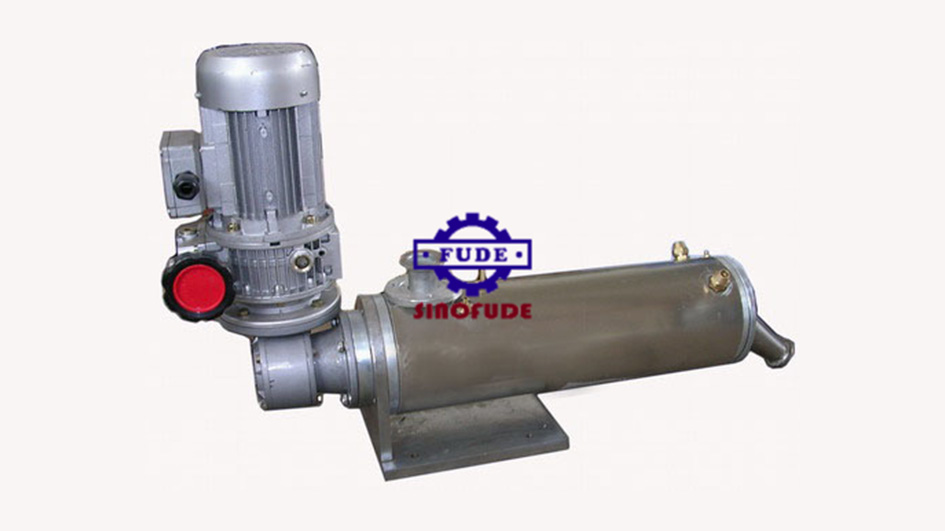

4- Lub tshuab nqus tsev vacuum

Cov lus piav qhia ntawm lub tshuab nqus tsev ua noj:

Lub tshuab nqus tsev puv puv tsis siv neeg no yog cov cuab yeej zoo tshaj plaws rau kev ua noj cov khoom qab zib nyuaj, nws yog qhov ua noj tsis tu ncua thiab lub tshuab nqus tsev ua haujlwm, nws yog lub tshuab ua ntej rau kev ua noj khoom qab zib nyuaj es tsis txhob siv lub tshuab nqus tsev vacuum.

1. Kev ua haujlwm ntawm qhov system yog ua noj tas li thiab lub tshuab nqus tsev.

2. Qhov zoo tshaj plaws tshav kub pauv, ua rau kev ua noj zoo thiab sib npaug.

3. Kev lag luam hauv nruab nrab thiab tswj los ntawm lub txee, yooj yim ua haujlwm thiab tswj xyuas.

4. Tso tawm los ntawm lub twj tso kua mis lossis kev tso tawm dawb yog muaj rau kev ua haujlwm sib txawv.

Dej cycling style lub tshuab nqus tsev twj tso kua mis thiab lub chamber loj ua rau kev tswj kom zoo dua ntawm cov dej noo thiab qhov kub thiab txias ntawm qhov kawg siav loj.

5-xim tsw inline tov khoom

Cov lus piav qhia ntawm inline mixer:

Qhov no inline mixer yog ua hauj lwm ua ke nrog lub tso zis twj tso kua mis. Cov qauv sab hauv ntawm cov khoom sib tov yog muaj peb feem, ntsia hlau thawb, cov hniav rotary thiab kho cov hniav. Rotary hniav yog tsau rau ntawm lub rotary ncej thiab tswj los ntawm lub ceev adjustable lub cev muaj zog.

Kev pub mis ntawm cov xim, tsw thiab kua qaub los yog kua gelatin yog muaj nyob rau ntawm cov kav dej saum toj kawg nkaus ntawm qhov thawb ntsia hlau.

6-xim tsw tuav thiab dosing system

Kev piav qhia ntawm cov xim thiab tsw tuav thiab dosing system:

Cov xim, tsw tuav thiab dosing system yog muaj kua xim thiab tsw tuav tank, dosing twj tso kua mis, piping thiab ncej txhawb.

Qhov loj ntawm lub tank thiab dosing twj tso kua mis yog nyob ntawm qhov muaj peev xwm ntawm qhov kev siv tshuaj, 10L ~ 100L ntawm lub tank yog muaj thiab cov twj tso kua mis muaj peev xwm kho tau manually lossis los ntawm PLC& HMI. Lub twj tso kua mis tuaj yeem xaiv los ntawm LMI ntawm Asmeskas hom lossis RDOSE ntawm GERMANY hom.

7- Cua txias conveyor

Cov lus piav qhia ntawm lub tshuab cua txias:

Lub tshuab cua txias no yog tsim los ntawm stainless hlau cua txias siv nrog tsav thiab dej chilling system.

Txoj siv cua txias yog stainless hlau siv los ntawm SANVIK, uas yog nto moo nyob rau hauv lub ntiaj teb no los ua stainless hlau siv, tsis muaj khoov thiab txias kev ua tau zoo yog zoo meej. Txoj siv yog txias los ntawm txau dej txias hauv qab txoj siv.

Qhov kawg kub ntawm qhov loj yog nyob ntawm qhov khiav ceev ntawm lub nruas thiab siv thiab cov dej txias txias.

8-Kev thauj khoom conveyor

Kev piav qhia ntawm lub tshuab conveyor:

Lub tshuab conveyor yog muaj ob feem uas yog hopper noj thiab conveyor siv thauj. Kev thauj ceev yog adjustable.

9-Batch roller

Kev piav qhia ntawm batch roller:

Cov khoom siv no tsuas yog siv rau dov loj ntawm cov khoom qab zib nyuaj lossis chewy khoom qab zib, nws muaj lub thawv log, rau chais, riser, tswj lub thawv, thiab lwm yam.

10-Rope sizer

Nqe lus piav qhia ntawm txoj hlua sizer:

Cov khoom siv no tsuas yog siv rau qhov loj ntawm cov khoom qab zib nyuaj lossis chewy khoom qab zib, nws yog tsim los ntawm kev tsim lub log thiab tswj lub thawv. Nws yog siv los ua lub raj confection. Nws ua haujlwm nrog batch roller, extruder, sib sau tshuab thiab lwm yam.

11-High ceev Chain txoj kev tshuab

Nqe lus piav qhia ntawm cov khoom qab zib nyuaj chain forming tshuab:

Qhov no tuag txoj kev tshuab yog saw hom, nws yog tsim version uas muaj kev ua tau zoo dua kev ua tau zoo, zoo dua qub thiab tsawg nkim yog muaj.

1. Tsim raws li kev siv tshuab txawv teb chaws thiab cov txheej txheem ua haujlwm sab hauv.

2. Cov khoom siv tshiab tiam tshiab uas yog tshwj xeeb rau cov khoom qab zib uas tuag.

3. tuaj yeem tsim ntau hom khoom qab zib nyuaj, txiv hmab txiv ntoo candies thiab cov khoom qab zib muaj jam lossis hmoov chaw, nrog rau kev xaiv los ntawm cov neeg siv khoom rau daim ntawv ntawm cov khoom qab zib nyuaj los ntawm kev hloov cov khoom qab zib pwm.

12-Swing discharger

13-Lub qhov dej txias

Qhov txias txias ntev: 6meter, Tag nrho ntev: 7meter

Inverter ceev kho: 0 ~ 6m / min, Kis zog: 4kw

Fridge: 10 tub yees, Dej txias ntauwd

Yas lossis wiremesh siv: 3 txheej, Conveyor siv dav: 1000mm

Tshuab zoo:

Cov neeg siv khoom hauv peb lub Hoobkas:

Tshuab hauv peb lub hoobkas:

Hu rau peb

Cia li tso koj tus email lossis tus lej xov tooj ntawm daim foos tiv tauj kom peb tuaj yeem muab kev pabcuam ntxiv rau koj!ontact form yog li peb tuaj yeem muab kev pabcuam rau koj ntxiv!

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.