Mohala oa tlhahiso ea lipompong tse thata ke sesebelisoa se ikemetseng se sebelisoang ka ho khetheha bakeng sa tlhahiso ea lipompong tse thata, tse kenyelletsang haholo mehato e kang ho kopanya tsoekere, ho belisa tsoekere, ho pholisa, ho hatakela le ho paka. Moralo le tlhophiso ea mohala ona oa tlhahiso hangata li hlophisitsoe ho latela litlhoko tsa tlhahiso, tse ka fihlelang tlhahiso ea litekanyo tse fapaneng.

Mokhoa oa ho sebetsa:

1. Ho kopanya tsoekere: Kopanya lisebelisoa tse sa tšoaneng tse tala (tse kang tsoekere, tsoekere, metsi, joalo-joalo) hammoho ho etsa sirapo.

2. Ho belisa tsoekere: Chesa sirapo e tsoakiloeng mochesong o itseng ho fihlela tekanyo ea tsoekere e loketseng ho etsa tsoekere e thata.

3. Ho pholisa: Sirapo e futhumetseng e hloka ho pholile ho etsa motsoako o thata oa lipompong o loketseng ho etsoa.

4. Ho theha: Sirapo e pholileng e kenngoa mochine oa ho phunya 'me sebōpeho sa eona se kenngoa ka har'a lipompong tse thata ka hlobo e khethehileng.

5. Packaging: Ka mor'a hore pompong e thata e entsoeng e pholile 'me e tiise, e kenngoa ka mochine oa ho paka o ikemetseng.

Lintlha tse ka Sehloohong tsa SINOFUDE Fully Automatic Die Hard Sugar Production Line:

1. Ho sebetsa ka mokhoa o phahameng: Mohala ona oa tlhahiso o ka sebetsa ka potlako sirapo e phehiloeng 'me oa sebetsa o sa khaotse bakeng sa lihora tse 24.

2. Taolo ea boleng: Ka ho laola ka nepo litekanyetso tsa mohato ka mong, boleng le tatso ea lipompong tse thata li ka netefatsoa.

3. Boemo bo phahameng ba boiketsetso: Ts'ebetso eohle ho tloha ho kopanya lihlahisoa tse tala ho ea ho ho etsa tsoekere e thata, ho ea ho liphutheloana, e ka iketsetsa, e fokotsa haholo ho kenella ka letsoho, ho ntlafatsa katleho ea tlhahiso le boleng ba sehlahisoa.

4. Phapang: Ka ho nkela liforomo tse fapaneng sebaka, libopeho tse fapaneng le boholo ba lipompong tse thata li ka hlahisoa ho fihlela tlhoko ea 'maraka.

Paramethara:

1-Auto Weighing le ho kopanya tsamaiso

Tlhaloso ea sistimi ea ho bekha le ho kopanya:

Thepa ea kichineng e fana ka boima bo fetang bo itekanetseng le ho kopanya thepa e tala le lipalangoang tsa inline ho ea ho karolo e le 'ngoe kapa ho feta tsa tlhahiso. E boetse e theha motheo oa tlhahiso e tsoelang pele. Ke mokhoa oa ho lekanya li-auto-ingredient bakeng sa ho sebetsana le indasteri ea li-confectionery. Tsoekere le lisebelisoa tsohle tse tala li ikakhela ka setotsoana le ho kopanya ho kenya. Tekanyo ea mechine, PLC e laoloa. Litanka tsa metsoako li hokahane ka sistimi e laoloang ea PLC e nang le mohopolo. Recipe e hlophisitsoe 'me metsoako e lekanngoa ka nepo ho tsoela pele ho kena ka har'a sejana se tsoakang. Hang ha metsoako eohle e kenngoa ka sekepeng, ka mor'a ho kopanya, boima bo tla fetisetsoa lisebelisoa tsa ho sebetsa. Litlolo tse ngata tsa lipompong li ka hlophisoa mohopolong kamoo u ratang.

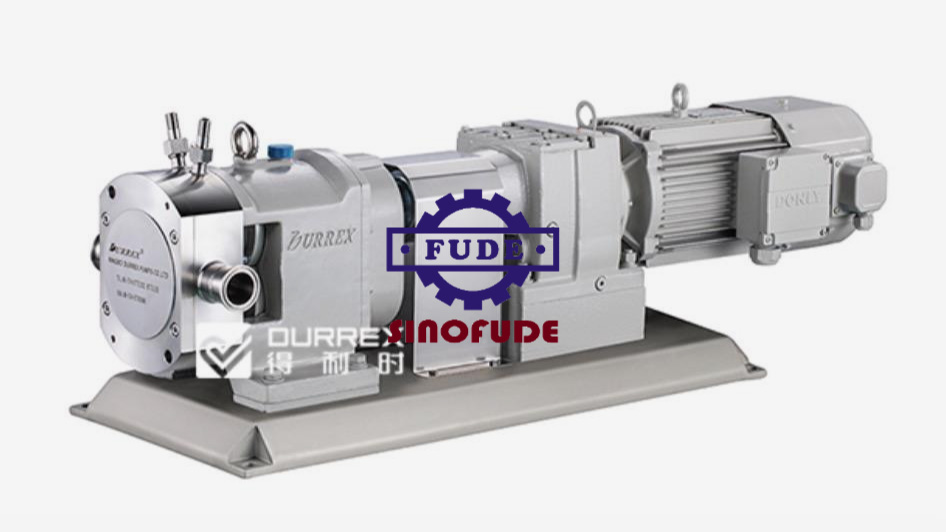

2-Pompo ea Lobe

Tlhaloso ea pompo ea gear:

Pompo ena ea lobe e sebelisetsoa ho fetisetsa thepa e tala e qhibilihisitsoeng ho tanka e ts'oereng.

E loketse ka ho khetheha bakeng sa sirapo e tsamaisang tanka ea polokelo kapa seapehi.

3-Tanka ea polokelo

Tlhaloso ea tanka ea polokelo:

Tanka ea polokelo e sebelisetsoa ho tšoara lisebelisoa tse tala tse qhibilihisitsoeng; Sehlahisoa se na le thepa ka tanka 'me se etsa hore sirapo e kene ka hare ho ts'ebetso e tsitsitseng.

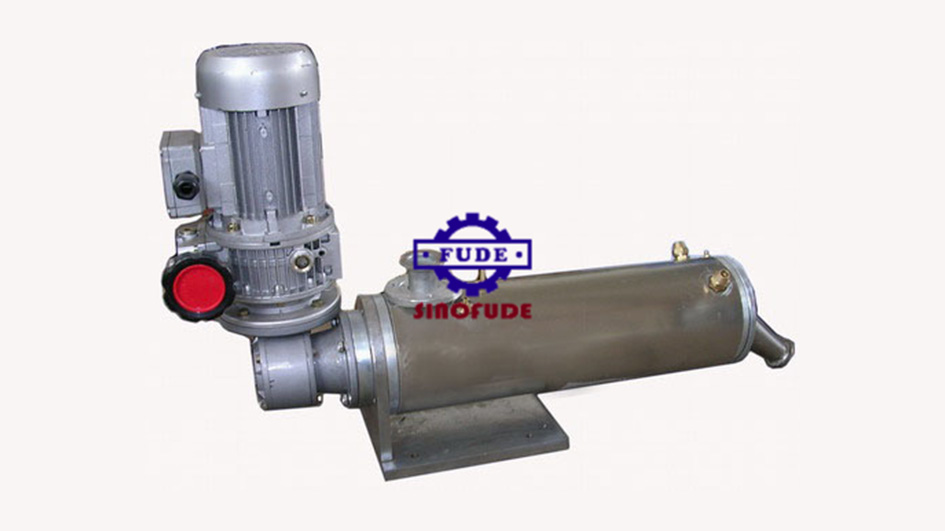

4-Seapehi sa vacuum

Tlhaloso ea sistimi ea ho pheha vacuum:

Sesebelisoa sena sa vacuum cooker se felletseng ke sesebelisoa se loketseng ho pheha lipompong tse phehiloeng ka thata, se lula se pheha le ho etsa vacuum, ke seapehi sa pele sa ho pheha lipompong tse thata ho fapana le batch vacuum cooker.

1. Ts'ebetso ea sistimi ke ho pheha ho tsoelang pele le ho etsa vacuum.

2. Phapanyetsano e nepahetseng ea mocheso, e etsa hore ho pheha hantle le ho lekana.

3. Ts'ebetso e bohareng le taolo ho tsoa ho khabinete, e sebetsa habonolo le ho e boloka.

4. Ho ntša ka pompo kapa ho ntša mahala ho fumaneha bakeng sa ts'ebetso e fapaneng.

Pompe ea vacuum ea mokhoa oa ho palama baesekele ea metsi le kamore e kholo e etsa taolo e betere ea mongobo le mocheso oa boima ba ho qetela bo phehiloeng.

5-Mobala o monate oa motsoako oa inline

Tlhaloso ea inline mixer:

Motsoako ona oa inline o sebetsa 'moho le pompo e ntšang metsi. Mohaho o ka hare oa motsoako o na le likarolo tse tharo, ho phunyeletsa ha screw, meno a rotary le meno a ho lokisa. Meno a rotary a tsepamisitsoe holim'a shaft ea rotary 'me a laoloa ke motlakase o khonang ho fetola lebelo.

Phepelo ea 'mala, tatso le asiti kapa gelatin e metsi e fumaneha liphaepheng tse kaholimo ho karolo ea "screw screw".

6-Mebala ea ho ts'oara tatso le sistimi ea dosing

Tlhaloso ea 'mala le tatso e ts'oereng le sistimi ea dosing:

'Mala, tatso le mokhoa oa ho noa li entsoe ka 'mala o mokelikeli le tanka e nang le tatso, pompo ea dosing, liphaephe le tšehetso ea foreimi.

Boholo ba tanka le pompo ea dosing bo ipapisitse le matla a sistimi ea dosing, 10L ~ 100L ea tanka ea fumaneha mme matla a pompo ea dosing a ka fetoloa ka letsoho kapa ho tsoa ho PLC.& HMI. Pompo ea dosing e ka khethoa ke LMI ea mofuta oa USA kapa RDOSE ea mofuta oa JEREMANE.

7-Cooling conveyor

Tlhaloso ea lebanta la ho pholisa:

Sistimi ena ea ho pholisa ka bongata e na le lebanta la ho pholisa la tšepe e sa hloekang le nang le sistimi e hatsetseng ea metsi.

Lebanta la ho pholisa ke lebanta la tšepe le sa hloekang le tsoang ho SANVIK, le tummeng lefatšeng ka bophara ho etsa lebanta la tšepe e sa hloekang, le se nang ho kobeha le ts'ebetso e phodileng e nepahetse. Lebanta le pholile ka ho fafatsa metsi a pholileng tlas'a lebanta.

Mocheso oa ho qetela oa boima o itšetlehile ka lebelo la ho matha la moropa le lebanta le mocheso oa metsi a pholileng.

8-Sepalangoang se tsamaisang thepa

Tlhaloso ea mochine oa conveyor:

Mochini oa conveyor o na le likarolo tse peli e leng ho fepa hopper le ho tsamaisa lebanta la conveyor. Lebelo la sepalangoang lea fetoha.

9-Batch roller

Tlhaloso ea batch roller:

Thepa ena e sebelisoa haholo-holo bakeng sa ho roala lipompong tse thata kapa lipompong tse chewy, e na le lebokose la mabili, li-roller tse tšeletseng, riser, lebokose la ho laola, joalo-joalo E sebetsa ka boholo ba ropo kapa ka mochini o tlatsang bohareng ho etsa lipompong tse tletseng setsi.

10-Thapo e kholo

Tlhaloso ea ropo sizer:

Thepa ena e sebelisoa haholo bakeng sa boholo ba lipompong tse thata kapa lipompong tse chewy, e entsoe ka lebili la ho etsa lebili le lebokose le laolang. E sebelisetsoa ho etsa tube ea confection. E sebetsa ka batch roller, extruder, mochini oa ho etsa joalo-joalo.

11-High speed Chain ho etsa mochine

Tlhaloso ea mochini oa ho etsa lipompong tse thata:

Mochini ona oa ho etsa die ke mofuta oa ketane, ke mofuta o ntlafalitsoeng o nang le ts'ebetso e ntle ea ho etsa, sebopeho se betere le tšenyo e nyane e fumanehang.

1. E entsoe ho latela theknoloji e tsoetseng pele ea linaha tse ling le mokhoa oa ho sebetsa ka hare.

2. Thepa e ncha e khethehileng bakeng sa lipompong tse thata tse entsoeng ka thata.

3. E ka etsa mefuta e fapaneng ea lipompong tse thata, lipompong tsa litholoana le lipompong li na le jeme kapa setsi sa phofo, ka khetho e hlokoang ke bareki bakeng sa mofuta oa lipompong tse thata ka ho nkela hlobo ea lipompong sebaka.

12-Swing discharger

13-Tonelo e phodileng

Bolelele ba kotopo e phodileng:6meter, Bolelele kaofela:7meter

Phetoho ea lebelo la inverter: 0 ~ 6m / min, matla a ho fetisa: 4kw

Sehatsetsi: 10 sehatsetsing, tora ea ho futhumatsa metsi

Lebanta la polasetiki kapa la wiremesh: mekhahlelo e 3, bophara ba lebanta la Conveyor: 1000mm

Boleng ba mochini :

Moreki fekthering ea rona:

Mochini fekthering ea rona:

Ikopanye le Rona

Tlohela lengolo-tsoibila kapa nomoro ea hau ea mohala foromong ea ho ikopanya hore re tle re u fe litšebeletso tse ling!

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.