Ulayini wokukhiqiza uswidi oqinile owenziwe nge-die-formed uyithuluzi elizisebenzela ngokugcwele elisetshenziselwa ukukhiqiza uswidi oqinile, ohlanganisa ngokuyinhloko izinyathelo ezinjengokuxuba ushukela, ukubilisa ushukela, ukupholisa, ukugxiviza, nokupakisha. Ukuklanywa nokuhlelwa kwalo mugqa wokukhiqiza kuvame ukuhlelwa ngokwezidingo zokukhiqiza, okungahlangabezana nokukhiqizwa kwezikali ezihlukene.

Ukuhamba komsebenzi:

1. Ukuxuba ushukela: Hlanganisa izinto ezingavuthiwe (njengoshukela, ushukela, amanzi, njll.) ndawonye ukuze wenze isiraphu.

2. Ukubilisa ushukela: Shisisa isiraphu exutshwe ezingeni elithile lokushisa ukuze ufinyelele izinga likashukela elifanele ukwenza ushukela oqinile.

3. Ukupholisa: Isiraphu eshisayo idinga ukupholiswa ukuze kwakheke uswidi oqinile olungele ukubunjwa.

4. Ukwakha: Isiraphu epholile ifakwa emshinini wokubhoboza futhi ukuma kwayo kugxivizwe kuswidi oqinile ngokusebenzisa isikhunta esikhethekile.

5. Ukupakisha: Ngemva kokuba uswidi oqinile owenziwe upholile futhi uqiniswe, uhlanganiswa kusetshenziswa umshini wokupakisha ozenzakalelayo.

Izici Eziyinhloko ze-SINOFUDE Fully Automatic Die Hard Sugar Production Line:

1. Ukusebenza kahle okuphezulu: Lo mugqa wokukhiqiza ungashesha ukucubungula isiraphu ebilisiwe futhi usebenze ngokuqhubekayo amahora angama-24.

2. Ukulawulwa kwekhwalithi: Ngokulawula ngokunembile imingcele yesinyathelo ngasinye, ikhwalithi nokunambitheka kwe-candy eqinile kungaqinisekiswa.

3. Izinga eliphakeme lokuzenzakalela: Yonke inqubo kusukela ekuxubeni kwezinto ezingavuthiwe kuya ekwakheni ushukela oqinile, ukupakisha, kungenziwa ngokuzenzakalela, kunciphise kakhulu ukungenelela okwenziwa ngesandla, ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

4. Ukuhlukahluka: Ngokufaka esikhundleni sokubunjwa okuhlukene, ubujamo obuhlukahlukene nobukhulu be-candy eqinile kungakhiqizwa ukuhlangabezana nesidingo semakethe.

Ipharamitha:

1-Ukukala okuzenzakalelayo kanye nohlelo lokuxuba

Incazelo yesistimu yokukala neyokuxuba:

Imishini yasekhishini inikeza okungaphezu kokulinganisa okuzenzakalelayo nokuxuba impahla eluhlaza nokuthutha okungaphakathi kweyunithi eyodwa noma ngaphezulu yokukhiqiza. Futhi kwakha isisekelo sokukhiqiza okuqhubekayo. Kuwuhlelo lokukala oluzenzakalelayo lwesithako lokucubungula imboni ye-confectionery. Ushukela nazo zonke izinto ezisetshenziswayo ziwukukala okuzenzakalelayo nokuhlanganisa ukufakwa. Ibhalansi yomshini, i-PLC ilawulwa. Amathangi ezithako axhunywe ngohlelo olulawulwayo lwe-PLC olunenkumbulo. Iresiphi ihlelwe futhi izithako zikalwa ngendlela efanele ukuze ziqhubeke nokungena emkhunjini wokuxuba. Lapho izithako seziphelele zifakwa emkhunjini, ngemva kokuxubana, inqwaba izobe idluliselwa kumishini yokucubungula. Izindlela zokupheka eziningi zamaswidi zingahlelwa kwinkumbulo ngendlela othanda ngayo.

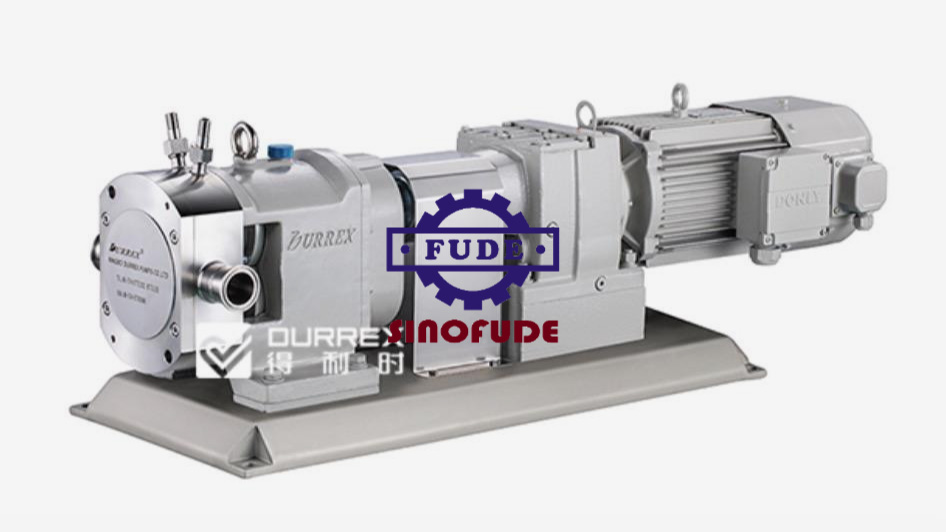

2-Iphampu ye-lobe

Incazelo yephampu yegiya:

Le futha ye-lobe isetshenziselwa ukudlulisa izinto zokusetshenziswa ezincibilikisiwe ethangini lokubamba.

Ilungele ngokukhethekile isiraphu yokuletha ethangini lokugcina noma kumpheki.

3-Ithangi lokugcina

Incazelo yethangi lokugcina:

Ithangi lokugcina lisetshenziselwa ukubamba izinto ezingavuthiwe ezincibilikisiwe; i-stirrer ifakwe ethangini futhi yenza isiraphu ngaphakathi ibambe ngokuqinile.

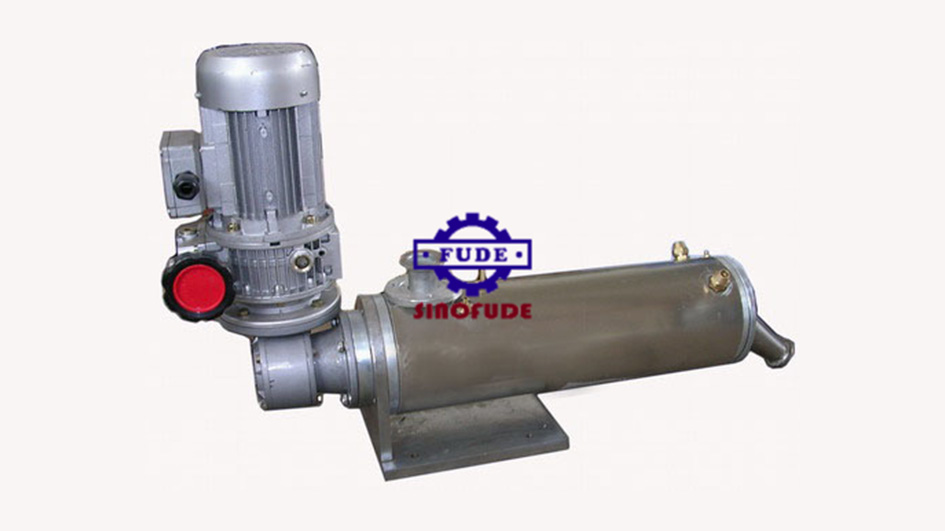

I-4-Vacuum cooker

Incazelo yesistimu yokupheka ye-vacuum:

Lesi sipheki esigcwele esizenzakalelayo siwumshini olungele ukupheka uswidi obilisiwe oqinile, sihlala sipheka futhi sisebenza nge-vacuum, siyisipheki sangaphambili sokupheka uswidi oqinile esikhundleni se-batch vacuum cooker.

1. Ukucutshungulwa kwesistimu ukupheka okuqhubekayo kanye nokusebenza kwe-vacuum.

2. Ukushintshaniswa kahle kokushisa, kwenza ukupheka kube kuhle futhi kulingane.

3. Ukusebenza okuphakathi nokulawula okuvela kwikhabhinethi, kusebenza kalula futhi kugcinwe.

4. Ukushajwa ngepompo noma ngokukhipha mahhala kuyatholakala ukuze kusetshenziswe okuhlukile.

Iphampu yevacuum yesitayela sokuhamba ngebhayisikili kanye negumbi elikhulu kwenza ukulawula okungcono komswakamo nezinga lokushisa lesisindo sokugcina esiphekiwe.

5-Inhlanganisela ye-flavour engaphakathi kombala

Incazelo ye-inline mixer:

Lesi sihlanganisi esisemgqeni sisebenza kanye nephampu ekhiphayo. Isakhiwo sangaphakathi se-mixer siqukethe izingxenye ezintathu, ukusunduza ngezikulufu, amazinyo ajikelezayo namazinyo okulungisa. Amazinyo ajikelezayo agxilile ku-rotary shaft futhi alawulwa yi-motor eguquguqukayo ngesivinini.

Ukuphakelwa kombala, ukunambitheka kanye ne-asidi noma i-gelatin ewuketshezi kuyatholakala kumapayipi angaphezu kwengxenye yesikulufu esiphushayo.

6-Umbala wokubamba ukunambitheka kanye nesistimu yokudosa

Incazelo yombala ne-flavour yokubamba kanye nesistimu yokudosa:

Umbala, indlela yokubamba ukunambitheka kanye nesistimu yokudosa iqukethe umbala owuketshezi kanye nethangi eliphethe ukunambitheka, iphampu yokudosa, ukusekela amapayipi kanye nohlaka.

Usayizi wethangi kanye nephampu yokudosa kuncike kumthamo wesistimu yokudosa, i-10L ~ 100L yethangi iyatholakala futhi umthamo wepompo yokudosa ungalungiseka ngesandla noma ku-PLC.& HMI. Iphampu yokudosa ingakhethwa yi-LMI yohlobo lwase-USA noma i-RDOSE yohlobo lwase-GERMANY.

7-Ukupholisa i-conveyor

Incazelo yebhande lokupholisa:

Lolu hlelo lokupholisa ngobuningi luqukethe ibhande lokupholisa lensimbi engagqwali elinesistimu yokupholisa eqhutshwayo namanzi.

Ibhande lokupholisa ibhande lensimbi engagqwali elivela kwa-SANVIK, elidume emhlabeni wonke ukwenza ibhande lensimbi engagqwali, alikho ukugoba nokusebenza kokupholisa kulungile. Ibhande lipholiswa ngokufafaza amanzi abandayo ngaphansi kwebhande.

Ukushisa kokugcina kwenqwaba kuya ngesivinini sokugijima sesigubhu nebhande kanye nezinga lokushisa lamanzi abandayo.

8-Isihambisi sezokuthutha

Incazelo yomshini wokuthutha:

Umshini wokuthutha uqukethe izingxenye ezimbili okuwukuphakela i-hopper kanye nokuthutha ibhande le-conveyor. Isivinini sokuthutha siyalungiseka.

9-Inqwaba roller

Incazelo ye-batch roller:

Lo mshini usetshenziselwa ikakhulukazi ukugoqa uswidi oqinile noma uswidi ohlafunwayo, uqukethe ibhokisi lamasondo, ama-roller ayisithupha, isikhuphukeli, ibhokisi lokulawula, njll. Isebenza ngosayizi wezintambo noma ngomshini wokugcwalisa ophakathi ukwenza amaswidi agcwele isikhungo.

10-Usayizi wezintambo

Incazelo yosayizi wezintambo:

Lo mshini usetshenziselwa ukulinganisa ubukhulu beswidi eqinile noma uswidi ohlafunwayo, uqukethe isondo lokwakha kanye nebhokisi lokulawula. Isetshenziselwa ukwenza i-tube confection. Isebenza nge-batch roller, i-extruder, umshini wokwakha njll.

11-High speed Chain ukwakha umshini

Incazelo yomshini wokwenza uswidi oqinile:

Lo mshini wokufa uwuhlobo lwamaketanga, uthuthukisiwe osebenza kangcono, umumo ongcono kanye nokumoshwa okuncane okutholakalayo.

1. Idizayinelwe ngokusekelwe kubuchwepheshe obuphambili bangaphandle kanye nendlela yokucubungula yangaphakathi.

2. Imishini yesizukulwane esisha ekhethekile kumaswidi aqinile.

3. Ingakha izinhlobo ezahlukene zamaswidi aqinile, amaswidi esithelo kanye namaswidi ane-jam noma i-powder centre, futhi ukhetho oludingwa amaklayenti ukuze enze uswidi oqinile ngokushintsha isikhunta sikaswidi.

12-Swing discharger

13-Umhubhe wokupholisa

Ubude bomhubhe wokupholisa:amamitha angu-6, ubude obuphelele:amamitha angu-7

Ukulungiswa kwesivinini se-Inverter: 0~6m/min, Amandla okudlulisa:4kw

Isiqandisi: Isiqandisi esiyi-10, Umbhoshongo wokupholisa amanzi

Ibhande lepulasitiki noma le-wiremesh: izendlalelo ezi-3, ububanzi bebhande le-Conveyor: 1000mm

Ikhwalithi yomshini :

Ikhasimende efekthri yethu:

Umshini embonini yethu:

Xhumana Nathi

Vele ushiye i-imeyili yakho noma inombolo yocingo efomini lokuxhumana ukuze sikwazi ukukunikeza ngamasevisi engeziwe!ifomu lokuxhumana ukuze sikwazi ukukunikeza ngamasevisi amaningi!

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Wonke Amalungelo Agodliwe.