In today's wave of intelligent manufacturing sweeping traditional industries, a fully automated production line is quietly changing the manufacturing landscape of the confectionery industry.

In today's wave of intelligent manufacturing sweeping traditional industries, a fully automated production line is quietly changing the manufacturing landscape of the confectionery industry.

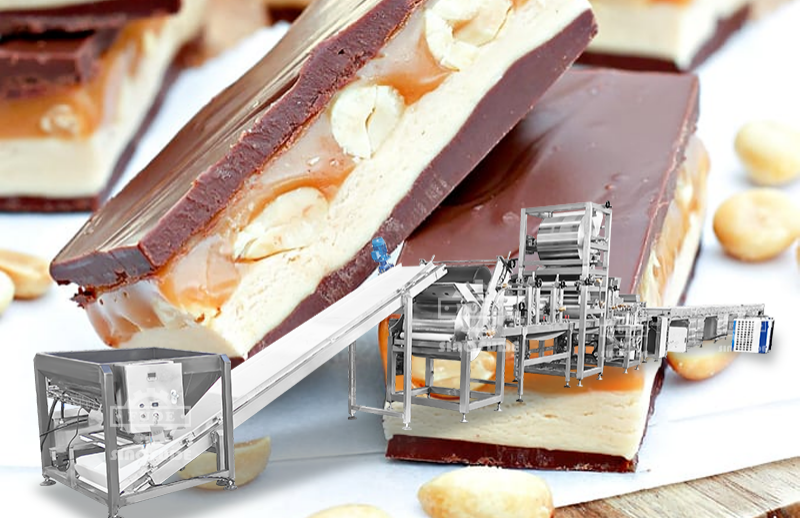

SINOFUDE Machinery Manufacturing Co., Ltd. recently officially launched its innovative automated production line for composite candy bars (Chocolate bar). This production line integrates complete processes such as raw material pretreatment, multi-layer filling production, chocolate coating, cooling and curing, and packaging, setting a new benchmark for the confectionery manufacturing industry.

Against the backdrop of the continued expansion of the global confectionery market, SINOFUDE, leveraging its professional manufacturing experience in confectionery equipment, chocolate equipment, and agar jelly equipment, launched this intelligent solution aimed at comprehensively improving production efficiency and product stability.

01 Company Strength and Technological Accumulation

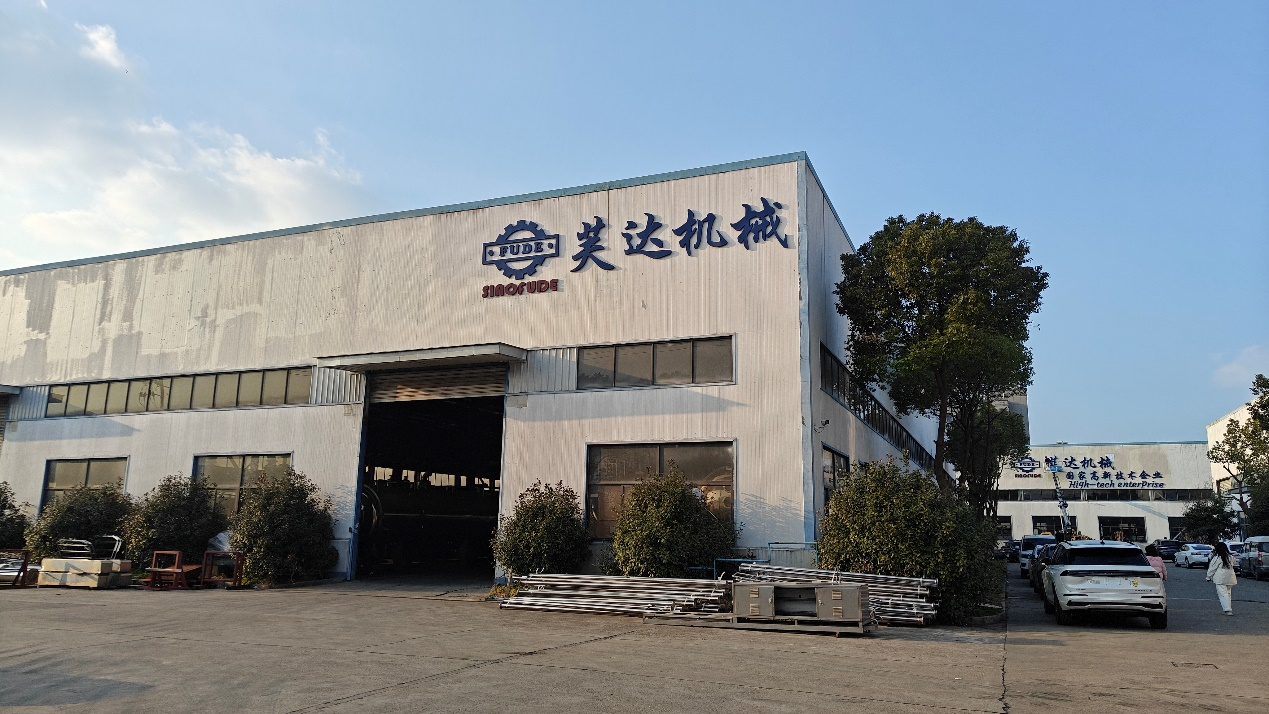

Since its establishment, SINOFUDE Machinery Manufacturing Co., Ltd. has focused on the food machinery manufacturing field, and in just a few years has developed into a significant player in the confectionery equipment manufacturing industry.

The company's main business covers multiple fields such as confectionery equipment, chocolate equipment, agar jelly equipment, and popping boba equipment, accumulating rich technical experience and industry knowledge.

In today's era where intelligent manufacturing has become the mainstream trend in the manufacturing industry, SINOFUDE Company keeps pace with the times, deeply integrating automation and intelligent concepts into its production line design, and launching this Chocolate bar production line, which is of revolutionary significance to the industry.

02 Core Advantages and Technological Innovations of the Production Line

As a confectionery product with a complex layered structure, Chocolate bar' production process involves multiple precision steps. SINOFUDE's production line breaks through many limitations of traditional confectionery production in its design.

The production line adopts a modular design concept, with each process step operating independently yet seamlessly connected, greatly improving the flexibility of equipment maintenance and process adjustments.

In the raw material pretreatment stage, the production line uses a precise temperature control system to ensure that caramel and nougat reach the ideal state during the cooking process. The preparation of the nougat layer uses precise temperature control and high-speed stirring technology to achieve the appropriate aeration effect in the raw materials, forming a unique fluffy texture.

For nuts such as peanuts, the production line is equipped with a professional roasting and grading system. Through specific temperature and time control, it ensures that the peanuts reach the appropriate crispness and are used according to product requirements.

03 Intelligent Control System and Automated Packaging

The intelligent control system is one of the biggest highlights of this production line. Through a central control platform, operators can monitor the operational status of each process step in real time and adjust parameters accordingly.

In the forming section, the production line achieves a fully automated production process. The nougat base is laid with controllable thickness using specialized equipment and undergoes preliminary shaping via a cooling system, providing a good foundation for subsequent processing.

In the chocolate coating stage, precise temperature control ensures the coating material remains in an ideal working state, achieving uniform coating, followed by cooling and shaping. Professional coating equipment effectively controls the coating thickness, ensuring consistent product appearance.

In the packaging stage, the production line integrates an advanced automated packaging system, enabling high-speed, continuous packaging operations. The system is equipped with multiple detection functions to ensure products meet quality standards.

The modern automated packaging system uses dual frequency converter control, allowing for instant bag length setting and cutting without the need for empty runs, achieving one-step processing, saving time and film; the human-machine interface makes parameter setting convenient and quick; and the fault self-diagnosis function makes fault displays clear at a glance.

04 Market Value and Industry Impact

The launch of SINOFUDE's Chocolate bar production line is a significant milestone for the confectionery manufacturing industry. It not only solves the pain points of low efficiency and unstable quality in traditional confectionery production, but also achieves precise quality control through intelligent technology.

For confectionery manufacturers, this production line provides a perfect solution for increasing production capacity and stabilizing quality. Its highly automated design significantly reduces reliance on manpower, helping companies adapt to the development trends of modern manufacturing.

The flexibility of the production line is also a major highlight. Through parameter adjustments and module replacements, companies can leverage a single production line to create a diverse product portfolio, meeting the diversified needs of modern consumers.

In today's food industry, where quality and safety are increasingly emphasized, this production line, through its intelligent control system, achieves end-to-end quality monitoring from raw materials to finished products, providing reliable assurance for product safety.

With the upgrading of the consumer market and the continuous increase in labor costs, production lines like SINOFUDE's, which integrate intelligence, high efficiency, and multiple functions, are becoming an inevitable choice for confectionery companies to enhance their competitiveness.

In the future, the confectionery manufacturing industry will witness the application of more technological innovations, and SINOFUDE's production line undoubtedly plays a leading role in this process.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.