With the continuous growth of the global confectionery market and the increasing demand for innovative products, Sinofude is proud to announce the successful launch of our Fully Automatic Chewing Gum Ball Production Line. Designed with efficiency, precision, and smart control at its core, this production line integrates advanced international technology with our own engineering innovations — marking another major milestone in Sinofude's candy machinery development.

The production line consists of Gum Base Oven, Sigma Mixer, Extruder, 9-Layer Cooling Tunnel, Gumball Forming Machine, Coating Pan, and Double Twist Packaging Machine, forming a complete automatic process that covers heating, mixing, extruding, cooling, forming, coating, and packaging. With centralized PLC control and intelligent coordination between units, the entire line enables one-touch operation, significantly improving productivity while ensuring product consistency and reducing labor costs.

Precision Engineering for Premium Quality

The process begins with the Gum Base Oven, which precisely melts and maintains the gum base at a stable temperature. The even heat distribution ensures that the gum base retains its ideal viscosity and elasticity, providing perfect preparation for the mixing stage.

Next, the Sigma Mixer equipped with dual Z-shaped arms and variable frequency control thoroughly blends the gum base with sugar, softeners, colorants, and flavors. The result is a uniform mixture that ensures excellent chew texture and consistent taste.

The mixed material is then continuously extruded by the Extruder, which uses a screw-driven system for precise shaping and stable material output. The extruded strips provide a uniform base for subsequent cooling and forming operations.

Efficient Cooling and Accurate Forming

After extrusion, the gum strips enter the 9-Layer Cooling Tunnel, an advanced temperature-controlled system that ensures even cooling across all layers. The tunnel’s multi-level circulating air channels shorten cooling time while maintaining the internal structure and elasticity of the gum.

Following cooling, the material proceeds to the Gumball Forming Machine, where it is cut, rolled, and shaped into perfectly round balls. Using servo-driven synchronization technology, this machine achieves high-speed forming with dimensional accuracy within ±0.2 mm, guaranteeing smooth surfaces and consistent size — essential for premium chewing gum ball production.

Smart Coating and High-Speed Packaging

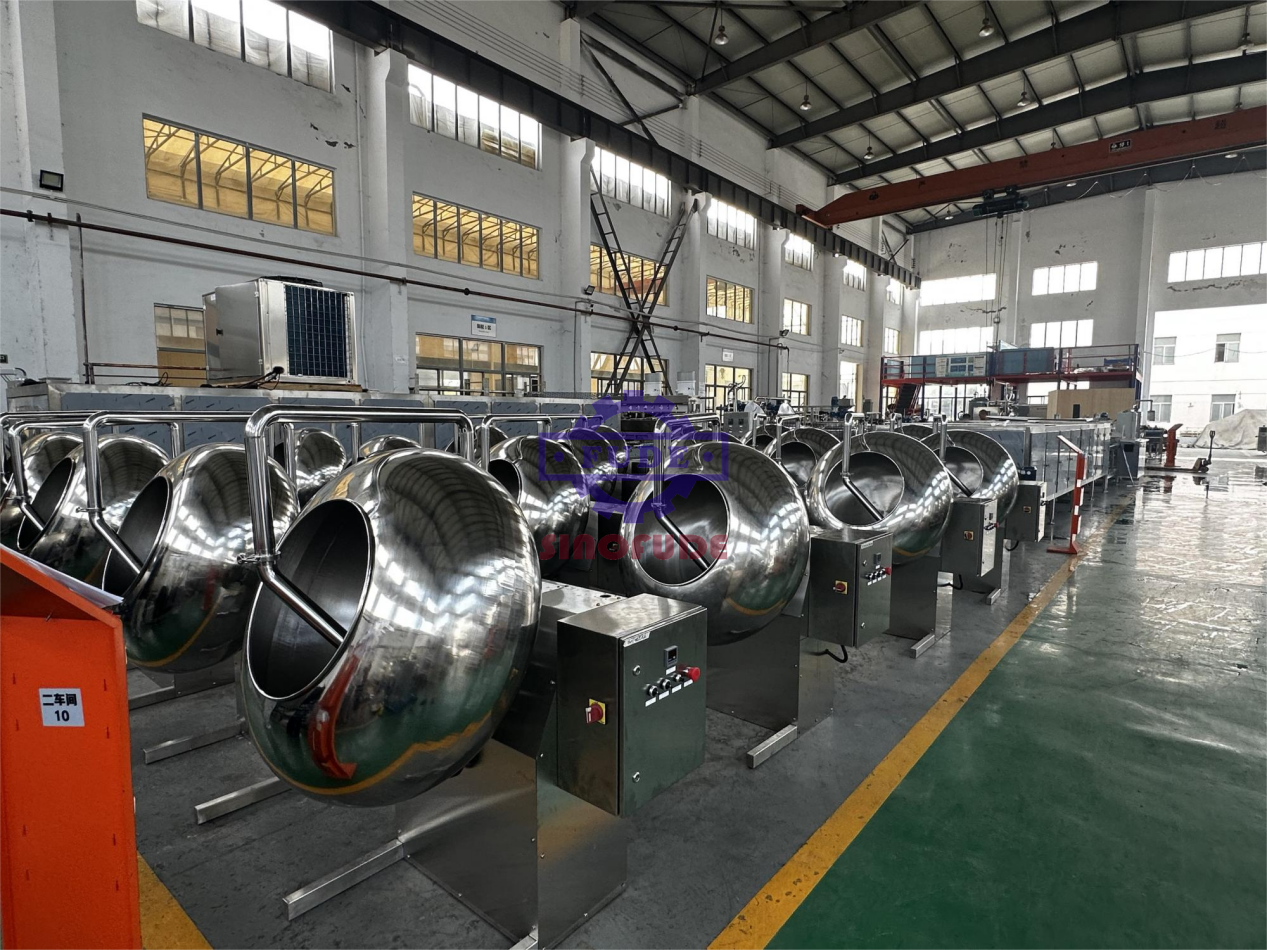

Once formed, the gum balls are transferred to the Coating Pan, where they undergo a series of sugar or color coating cycles. The automated spraying and hot-air drying system allows precise control over coating thickness and gloss level, producing brilliant colors and a crisp outer shell that enhances flavor and appearance.

After coating and final cooling, the products move on to the Double Twist Packaging Machine, which features automatic counting, positioning, and double-twist wrapping. This machine ensures tight, beautiful packaging suitable for various gum ball sizes and wrapping materials.

Smart Control and Reliable Performance

The entire line is operated through an integrated PLC + HMI control system, offering real-time monitoring, data logging, and remote maintenance capabilities. Production parameters are visualized and traceable, supporting efficient quality control and preventive maintenance.

Key components, including the control system, drives, and pneumatic elements, are sourced from renowned international brands such as SIEMENS and FESTO, ensuring stable performance, long service life, and ease of maintenance.

Driving the Future of Confectionery Automation

The successful commissioning of this chewing gum ball production line strengthens Sinofude’s product portfolio and enhances ability to deliver complete solutions — from raw material processing to final packaging. It provides confectionery manufacturers, both traditional and emerging, with a reliable and highly automated solution that meets the demands of modern production.

Looking ahead, Sinofude will continue to invest in research and development, bringing more automation, digitalization, and sustainability to the candy manufacturing industry. By combining innovative engineering with advanced control systems, Sinofude aim to help confectionery producers worldwide achieve higher efficiency, better quality, and greater competitiveness in the global market.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.