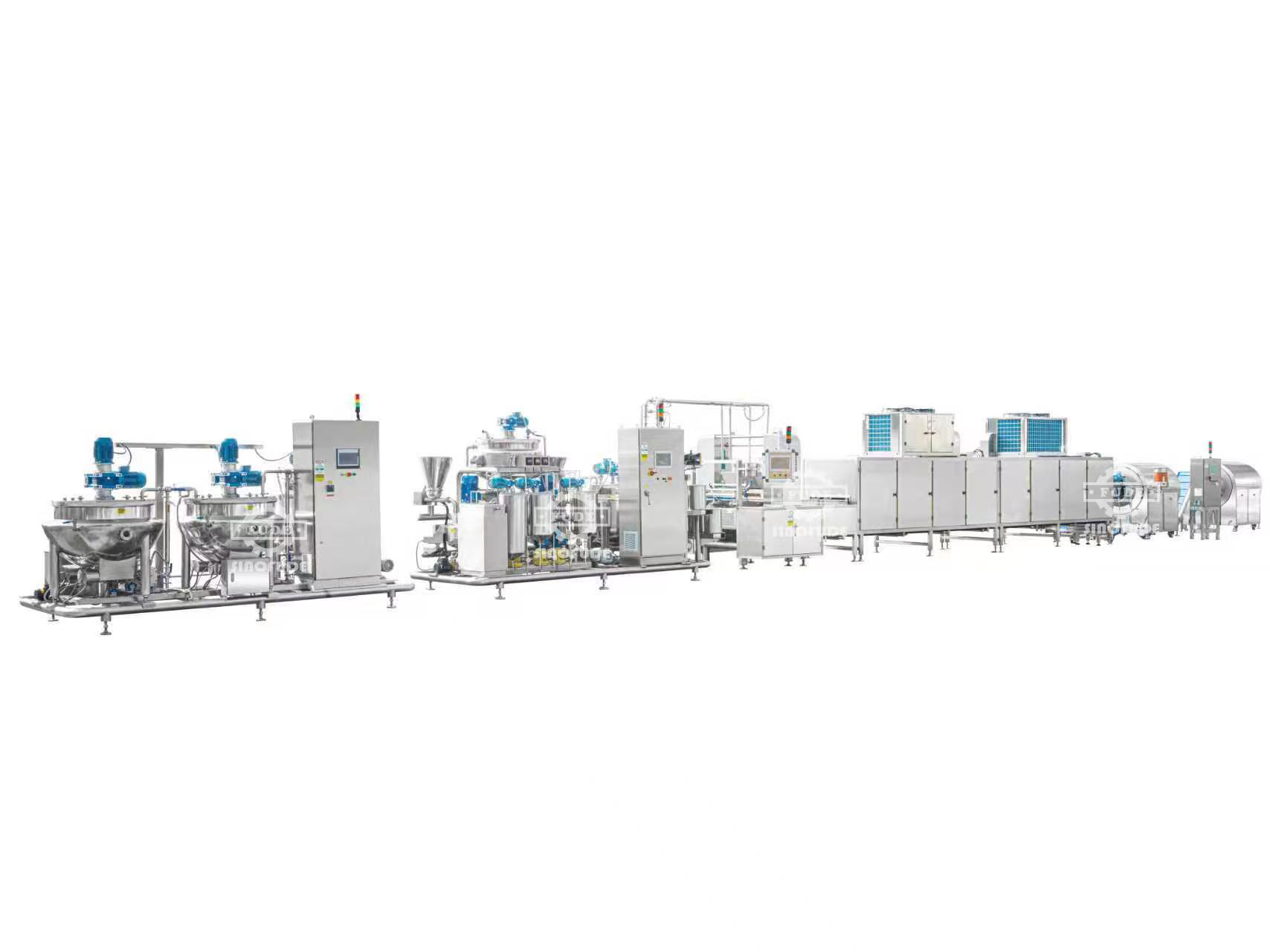

Shanghai, China – With the rapid growth of functional confectionery and sports nutrition, creatine gummies are becoming a new favorite among fitness enthusiasts and young consumers in overseas markets. Building on years of experience in gummy production lines, Shanghai Fude Machinery Manufacturing Co., Ltd. has launched a new “Creatine Functional Gummy Smart Production Line Solution”. Centered on the CLM series automatic gummy depositing line, the solution provides global customers with one‑stop support from concept and formulation ideas to process design and complete equipment.

Functional Gummies on the Rise: A New Opportunity for Creatine Gummies

In recent years, functional gummies have been replacing traditional tablets and powders to become a key dosage form for vitamins, minerals and sports nutrition products. In overseas markets, creatine gummies are promoted as “tasty, convenient and easy to stick with”. A common specification is about 1 g of creatine per gummy, with three gummies per day meeting the usual daily intake; a bottle of 60–150 pieces typically retails for USD 13–25, far above the price level of regular fruit gummies.

Against this backdrop, many confectionery factories, dietary supplement manufacturers and sports nutrition brands are looking for ways to quickly enter high‑margin segments such as creatine gummies, protein gummies and electrolyte gummies by upgrading their existing gummy lines.

From Formula to Process: A One‑Stop Solution Using Creatine Gummies as an Example

Based on mature creatine gummy cases in overseas markets and its own experience in customized gummy projects, Fude has developed a creatine gummy process solution suitable for capacities from 80 to 600 kg/h. On the formulation side, the solution takes a traditional fruit gummy base and optimizes sugar‑solid content, gel system and pH buffer system to create a stable window for creatine and other functional ingredients, while maintaining good texture and appearance.

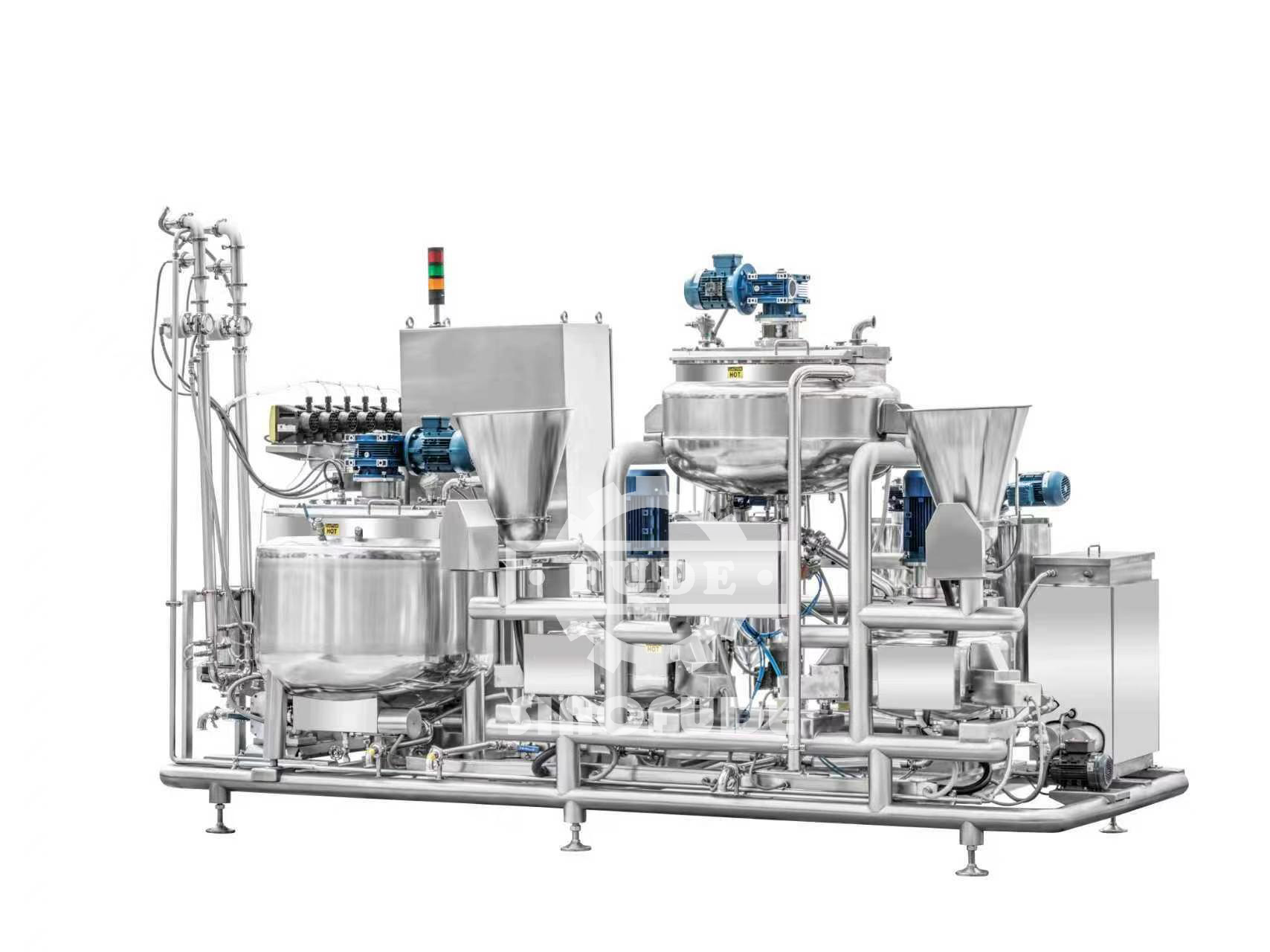

On the process side, the recommended production flow is: automatic weighing and mixing → sugar dissolving and vacuum cooking → holding and de‑aeration → online addition of creatine, acid and flavors/colors → CLM depositing and forming → cooling → demoulding and oiling/powdering → maturation and packaging.

CLM Automatic Gummy Depositing Line: Designed for High‑Value Functional Gummies

In this creatine gummy solution, the CLM automatic gummy depositing line is the core of the system. The CLM series can handle single‑color, two‑color and center‑filled depositing, and is suitable for bears, fruit shapes, bars and many other designs. Servo‑driven depositing ensures precise control of each row and each cavity, so the weight of every gummy – and thus the creatine dosage – stays within tight tolerances and complies with regulatory requirements.

Because creatine is sensitive to high temperature, the solution reserves an online functional‑slurry dosing and dynamic mixing module just upstream of the depositor. Creatine is pre‑dissolved into a concentrated slurry and mixed with the main syrup at 70–80°C, followed by immediate depositing. This approach helps reduce possible degradation while keeping the texture stable.

Raw Material Cost and Retail Price: One Line Unlocks a High‑Margin Product Portfolio

Taking a typical formulation as an example, each kilogram of creatine gummies contains about 0.2 kg of creatine monohydrate. Based on bulk creatine prices of approximately USD 5–7/kg on the international market, and adding sugar syrup, gelatin/pectin, acids, flavors and colors, the total raw‑material cost is roughly USD 2.3–2.6/kg. Including labor, utilities, depreciation and packaging materials, the overall production cost can usually be kept in the range of USD 3–3.5/kg.

For a bottle of 60 gummies with a net weight of around 0.3 kg, the combined ex‑factory cost is therefore about USD 0.9–1.1 per bottle. Given current retail prices of USD 13–25 per bottle for creatine gummies in overseas markets, even at an ODM ex‑factory price of USD 4–6 per bottle, brand owners still enjoy attractive profit margins, while the payback period for the production line investment is significantly shortened.

Key Advantages of Using Fude Gummy Lines for Creatine Products

· Multi‑purpose production: starting from an existing fruit gummy or vitamin gummy process, customers only need to add a functional‑ingredient premixing tank and online dosing module to upgrade to creatine gummies, electrolyte gummies and other high‑margin products, greatly improving line utilization.

· Stable dosage: servo‑driven CLM depositors together with precision mould design keep unit weight deviations low, which is critical for meeting label claims on “amount per serving” in different regulatory markets.

· Easy cleaning: the line supports CIP cleaning and modular section design, reducing cross‑contamination risks when switching between flavors and different functional products.

· Flexible capacity: from pilot‑scale batches of a few dozen kilograms per hour to 300–600 kg/h industrial lines, there are suitable models for both new product development and large‑scale commercial production.

· Global service: backed by multiple international installation references and remote support capability, Fude can assist customers with process verification, plant layout, commissioning and operator training.

Company Perspective and Market Outlook

“In the past few years we have helped many customers develop vitamin gummies and collagen gummies. Now we see very strong growth in creatine gummies and energy gummies in overseas markets,” said a spokesperson for Shanghai Fude Machinery. “With this creatine functional gummy production‑line solution, we hope to make it easier for traditional confectionery factories to enter the sports nutrition field and supply both snack and health‑oriented products on the same line.”

Looking ahead, Shanghai Fude Machinery will continue to focus on functional confectionery, sugar‑free and low‑sugar formulations and plant‑based gel systems. Together with partners around the world, Fude aims to develop more high‑value product solutions and help customers capture new opportunities in the next wave of confectionery upgrades.

About Shanghai Fude Machinery Manufacturing Co., Ltd.

Shanghai Fude Machinery Manufacturing Co., Ltd. specializes in the R&D and manufacturing of production lines for gummies, hard candies, popping boba, chocolate, biscuits and bakery products. With CE and other certifications, Fude’s equipment has been exported to Europe, Southeast Asia, South America, the Middle East and many other regions. The company is committed to providing safe, efficient and flexible intelligent food‑equipment solutions for customers worldwide.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.