Ukubamba impahla eluhlaza: uhlelo lokupheka lomshini we-gummy

Ukulungiswa Kwesiraphu: Isiraphu ingenye yezithako eziyinhloko zama-gummies. Endaweni yokuphatha impahla eluhlaza, amathangi amakhulu okuxuba lapho ushukela namanzi kuhlanganiswa khona asetshenziselwa ukulungisa isiraphu. Inani elifanele likashukela we-granulated liyengezwa emanzini ashisayo futhi lixutshwe kahle ngokugqugquzela ukwenza isiraphu ye-homogeneous yomshini wokwenza i-gummy.

Ukuxuba okungeziwe: I-gummy ehlukahlukene edliwayo, i-juice concentrate, flavour, pigments nezinye izithako zingangezwa isiraphu ukwandisa ukuthungwa, umbala kanye nokunambitha kwezinsini. Lezi zengezo zilawulwa ngamaresiphi anembayo kanye nemishini yokwenza i-gummy ezenzakalelayo, iqinisekisa ikhwalithi engaguquki ye-gummy kusuka kuqoqo kuye kwelinye.

Ukugqugquzela nokushisa: umshini wokwenza i-gummy wohlelo lokupheka

Ingxube yesiraphu nezinye izithasiselo kufakwa ohlelweni lokuphisa. Lapha, i-mixer inyakazisa ingxube ngokulinganayo ukuze kuqinisekiswe ukuthi izithasiselo nesiraphu zixutshwe kahle.

I-Heating hopper: Ingxube ishisiswa ngokushisisa isitimu noma isisetshenziswa sokushisisa sikagesi somshini wokwenza ushingamu ukusiletha ezingeni lokushisa elifanele. Inqubo yokushisisa yomshini we-gummy isiza ukuncibilikisa izingxenye eziqinile kusiraphu futhi ikhuthaze inqubo yokumisa eyenza i-gummy.

Umshini wokwenza i-gummy:

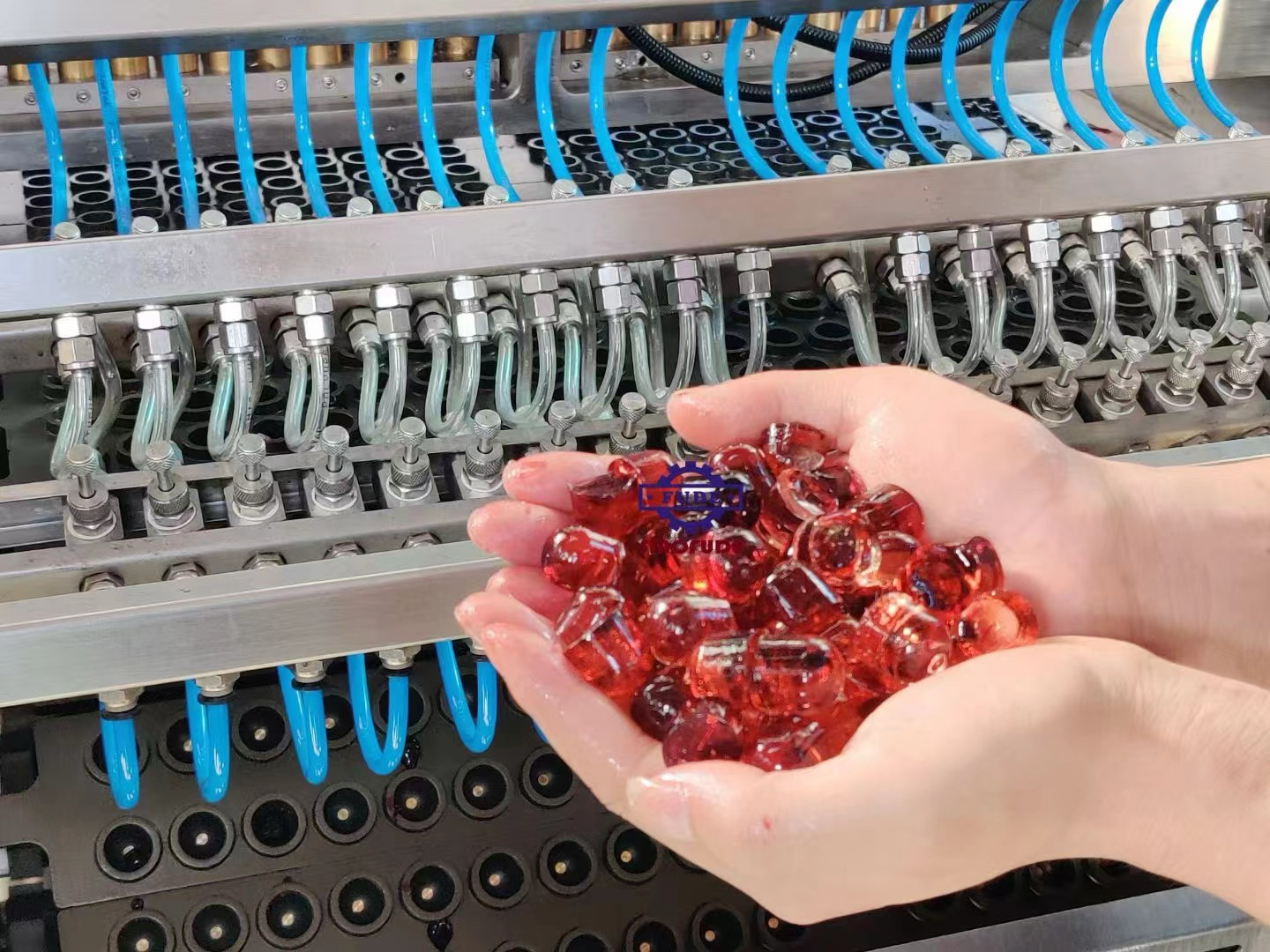

Imishini yokwenza i-gummy yomshini wokubumba: Ingxube eshisayo inikezwa umshini wokubumba we-gummy, oqukethe uchungechunge lwesikhunta. Lezi umshini gummy of isikhunta kungaba isikhunta se-silicone noma isikhunta sensimbi, esenziwe ngokwezifiso ngendlela oyifunayo nosayizi we-fondant.

Umjovo Nokugcwalisa: Ingxube yomshini we-gummy ijova ezibunjeni zemishini yokwenza i-gummy ngenani eliqondile lokugeleza, iqinisekisa ukuthi isikhunta ngasinye sigcwaliswa ngokulinganayo. Ngemuva kwenqubo yokugcwalisa, isikhunta semishini yokwenza i-gummy siyanyakaziswa noma sithinte kancane ukuze kuqedwe noma yimaphi amabhamuza omoya noma ama-voids futhi sinikeze i-fondant isakhiwo esifanayo.

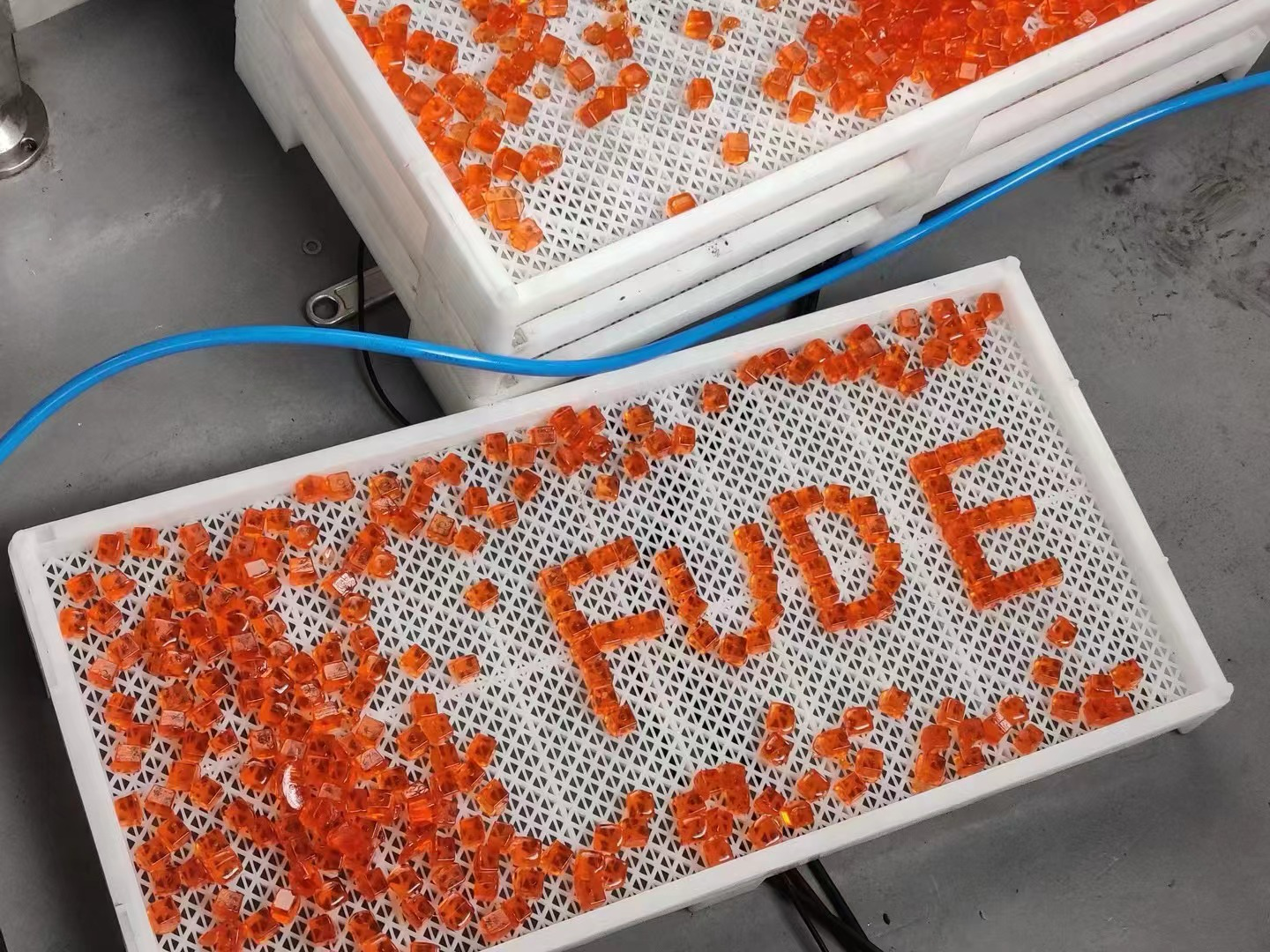

Ukupholisa nokuqinisa imishini yokwenza i-gummy:

Umhubhe wokupholisa: Isikhunta esigcwele somshini we-gummy singena emhubheni wokupholisa ngebhande lokuthutha. Emhubheni wokupholisa womshini we-gummy, umshini we-gummy upholiswa ngokushesha ngokufaka umoya obandayo noma amanzi aphansi okushisa kuwo. Lokhu kusheshisa ukusetha nokuqinisa inqubo ye-gummy.

Ukulawula isikhathi nezinga lokushisa: Isikhathi nezinga lokushisa emhubheni wokupholisa kungalungiswa ngokuya ngeresiphi ye-gummy kanye nezidingo. Izinhlobo ezahlukene ze-gummy zingase zidinge izikhathi zokupholisa ezihlukene namazinga okushisa ukuze kuqinisekiswe ukuthungwa okuhle nokuzwakala komlomo.

Iphakheji yemishini yokwenza i-gummy:

Umshini wokupakisha ozenzakalelayo we-gummy: Amaswidi athambile apholile futhi aqinisiwe apakishwa umshini wokupakisha ozenzakalelayo. Le mishini ingafinyelela amafomu okupakisha ahlukene njengoba kudingeka, njengezikhwama zepulasitiki, amabhokisi, amabhodlela noma amathini.

Isisindo esizenzakalelayo nokupakishwa: Ama-gummies athuthelwa endaweni yokukala neyokupakisha ngamabhande okuthutha noma amasistimu wezingalo zerobhothi ezizenzakalelayo. Lapha, ama-gummies akalwa ngokunembile futhi ahlukaniswe engxenyeni ngayinye yokupakisha ukuze kuqinisekiswe ukuthi iphakethe ngalinye lihlangabezana nesisindo esishiwo kanye nenani.

Ukuhlola Nokulawula Ikhwalithi:

Izinzwa nezinhlelo zokubona: Imishini ye-Gummy ivamise ukuhlonyiswa ngezinzwa ezihlukahlukene nezinhlelo zokubona ukuze ibone ikhwalithi nokuma kwezinsini. Lawa madivaysi omshini we-Gummy angakwazi ukubona ngokuzenzakalelayo isisindo, usayizi, ukubukeka nezinye izici ze-gummies ukuqinisekisa ukuthi umkhiqizo uhlangabezana nezindinganiso zekhwalithi.

Ukutholwa okudidayo: Izinzwa namasistimu okubona ayakwazi nokubona okudidayo kunqubo yokukhiqiza i-gummy yomshini we-Gummy, njengokukhubazeka, izinto zangaphandle, njll. Uma kutholwa okungavamile, isistimu yomshini we-Gummy izohlunga ngokuzenzakalelayo izinsini eziyinkinga kusukela umugqa wokukhiqiza ukuze kuqinisekiswe ukuthi imikhiqizo ehlangabezana namazinga kuphela iyapakishwa futhi ithunyelwe.

Ukudlulisa nokupakishwa komshini we-gummy:

Umshini we-Gummy wesistimu yokudlulisa: Ama-gummies apakishiwe adluliswa ngesistimu yebhande lokuthutha noma isistimu yengalo yerobhothi ezenzakalelayo ukusuka endaweni yokupakisha ukuya endaweni yokugcina yokugcina noma indawo yokuthumela.

Ukulandelela iqoqo: Umshini we-Gummy uvamise ukuhlonywa isistimu yokulandelela inqwaba engalandelela usuku lokukhiqiza, umthombo wempahla eluhlaza, inqubo yokukhiqiza nolunye ulwazi lweqoqo ngalinye lamaswidi e-gummy ukuze ulawule ikhwalithi nokulandeleka.

Isistimu ezenzakalelayo yomshini we-Gummy ithuthukisa kakhulu ukusebenza kahle kokukhiqiza nokuvumelana, inciphisa isidingo sokusebenza ngesandla, futhi iqinisekisa ikhwalithi yomkhiqizo kanye nezindinganiso zokuhlanzeka zomshini we-Gummy. Lo mshini we-Gummy ozenzakalelayo ungalungiswa kalula futhi unwetshwe ngokuya ngezidingo ukuze uhlanganise izinhlobo ezahlukene nezikali zomshini we-Gummy.

Xhumana Nathi

Vele ushiye i-imeyili yakho noma inombolo yocingo efomini lokuxhumana ukuze sikwazi ukukunikeza ngamasevisi engeziwe!ifomu lokuxhumana ukuze sikwazi ukukunikeza ngamasevisi amaningi!

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Wonke Amalungelo Agodliwe.