Raw material handling: gummy machine cooking system

Syrup Preparation: Syrup is one of the main ingredients of gummies. In the raw material handling area, large mixing tanks where sugar and water are mixed are used to prepare the syrup. An appropriate amount of granulated sugar is added to the heated water and mixed thoroughly by stirring to form a homogeneous syrup of gummy maker machine.

Additive mixing: Various edible gummy, juice concentrates, flavors, pigments and other ingredients can be added to the syrup to increase the texture, color and taste of the gummies. These additives are controlled through precise recipes and automated gummy maker equipment, ensuring consistent gummy quality from batch to batch.

Stirring and heating: gummy maker machine of cooking system

A mixture of syrup and other additives is fed into the brewing system. Here, the mixer stirs the mixture evenly to ensure that the additives and syrup are thoroughly mixed.

Heating hopper: The mixture is heated by steam heating or electric heating device of gummy making machine to bring it to the appropriate temperature. The heating process of gummy machine helps dissolve the solid components in the syrup and promotes the setting process that forms the gummy.

Gummy machine of forming:

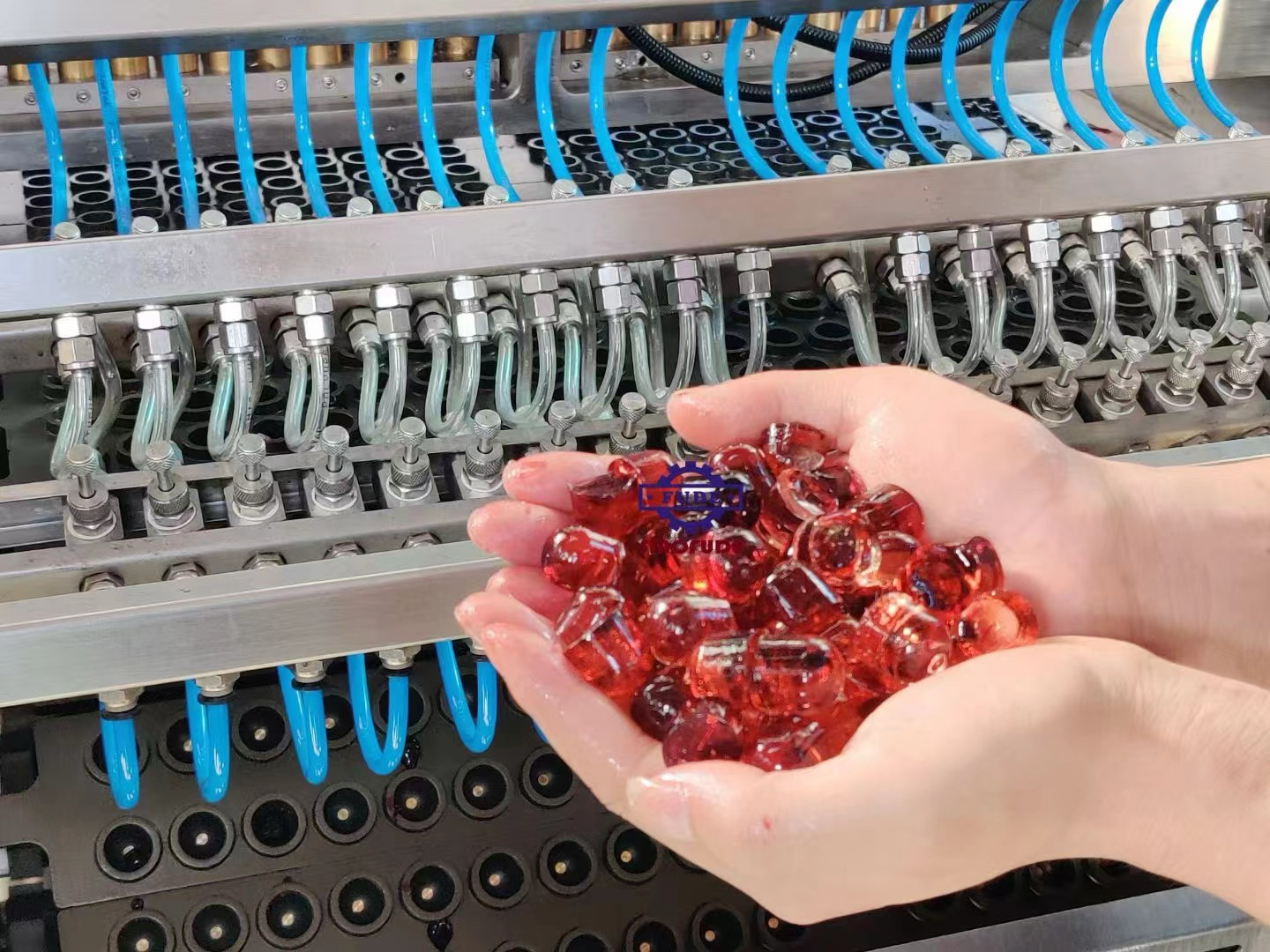

gummy making equipment of molding machine: The heated mixture is fed to a molding gummy machine, which contains a series of molds. These gummy machine of molds can be silicone molds or metal molds, customized to the desired shape and size of the fondant.

Injection and Filling: The mixture of gummy machine is injected into the molds of gummy making equipment at a precise flow rate, ensuring each mold is filled evenly. After the filling process, the mold of gummy making equipment is vibrated or lightly tapped to eliminate any air bubbles or voids and give the fondant a more uniform structure.

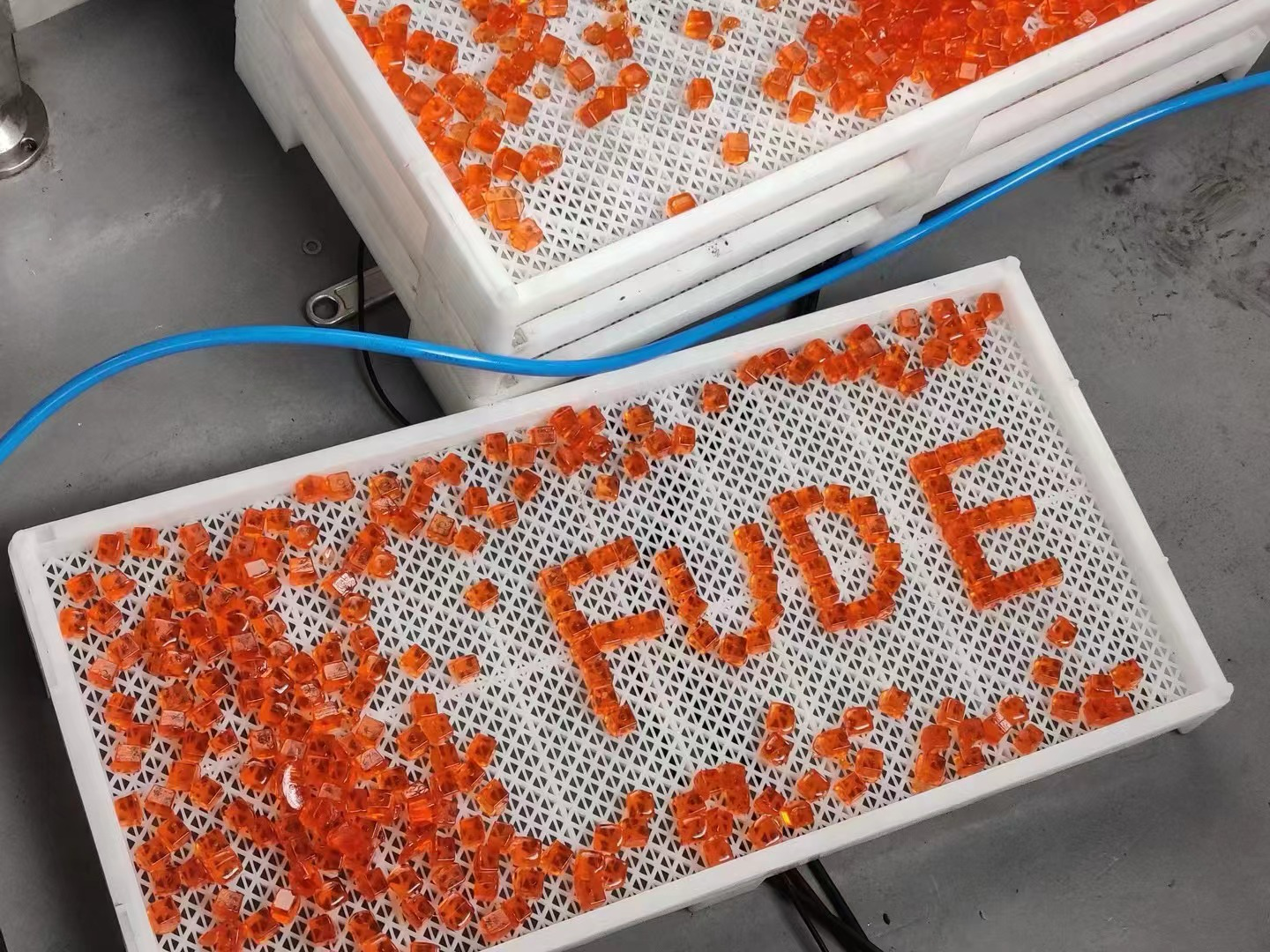

Cooling and solidification of gummy making equipment:

Cooling Tunnel: The filled mold of gummy machine enters the cooling tunnel through a conveyor belt. In a cooling tunnel of gummy machine, the gummy machine is cooled rapidly by applying cold air or low-temperature water to it. This speeds up the setting and solidification process of the gummy.

Time and temperature control: The time and temperature in the cooling tunnel can be adjusted according to the gummy recipe and requirements. Different types of gummy may require different cooling times and temperatures to ensure the ideal texture and mouthfeel.

Package of gummy making equipment:

Automatic gummy making equipment packaging machine: The cooled and solidified soft candies are packaged by the automatic packaging machine. These machines can achieve a variety of different packaging forms as required, such as plastic bags, cartons, bottles or cans.

Automatic weighing and packaging: Gummies are transported to the weighing and packaging area via conveyor belts or automated robotic arm systems. Here, the gummies are accurately weighed and portioned into each packaging unit to ensure each package meets the specified weight and quantity.

Testing and Quality Control:

Sensors and vision systems: Gummy machines are usually equipped with various sensors and vision systems to detect the quality and shape of the gummies. These devices of Gummy machine can automatically detect the weight, size, appearance and other characteristics of gummies to ensure that the product meets quality standards.

Anomaly detection: Sensors and vision systems are also able to detect anomalies in the gummy production process of Gummy machine, such as defects, foreign objects, etc. If an abnormality is detected, the system of Gummy machine will automatically sort the problematic gummies from the production line to ensure that only products that meet the standards are packaged and shipped.

Conveying and packaging of gummy machine:

Gummy machine of conveying system: The packaged gummies are conveyed through a conveyor belt system or an automatic robotic arm system from the packaging area to the final storage area or shipping area.

Batch tracking: Gummy machine are usually equipped with a batch tracking system that can track the production date, raw material source, production process and other information of each batch of gummy candies for quality control and traceability.

The automated system of the Gummy machine greatly improves production efficiency and consistency, reduces the need for manual operations, and ensures product quality and hygiene standards of Gummy machine. This automated Gummy machine can be flexibly adjusted and expanded according to needs to accommodate different types and scales of Gummy machine.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.