Embonini yamabhisikidi, imigqa yokukhiqiza amabhisikidi aqinile, njengemishini yobuchwepheshe eyisisekelo, isekela ukukhiqizwa okukhulu kwemikhiqizo yamabhisikidi aqinile njengamabhisikidi obisi, amabhisikidi e-vanilla, namabhisikidi amaqanda ngendlela yawo yobuchwepheshe eyingqayizivele nezici zenqubo. Lesi sihloko sizohlaziya ngendlela ehlelekile izici zobuchwepheshe, isimo samanje, namathrendi okuthuthuka kwemigqa yokukhiqiza amabhisikidi Aqinile ngokombono wemboni.

1. Uhlolojikelele lwamabhisikidi aqinile: Izimpawu nokuhlukaniswa

Amabhisikidi aqinile ahluke kakhulu kumabhisikidi acwebile ngokwendlela yokwakheka nokuthungwa. Ngokwezindinganiso zezimboni, amabhisikidi aqinile anesilinganiso esiphansi sikashukela kuwoyela, ngokuvamile agcina okuqukethwe kukashukela kungaphansi kwama-30% kanye nowoyela ngaphansi kuka-20%. Lokhu kuhluke kakhulu kunesilinganiso esiphezulu sikashukela-kuwoyela kumabhisikidi acwebile.

Izici ezibalulekile zamabhisikidi Aqinile zifaka: iphethini egobile kakhulu enezimbobo zokukhonkwane ngaphezulu, indawo ebushelelezi, isiqephu esiphambanayo esinezingqimba, kanye nokuthungwa okucwebezelayo, okuhlafunwayo. Lezi zici zitholakala ngokuqondile ekugelezeni kwenqubo ekhethekile yemigqa yokukhiqiza amabhisikidi Aqinile.

Amabhisikidi ajwayelekile aqinile ahlanganisa izinhlobonhlobo zezinhlobonhlobo, okuhlanganisa amabhisikidi obisi, amabhisikidi e-vanilla, amabhisikidi amaqanda, amabhisikidi kaMarie, namabhisikidi aseBoston. Le mikhiqizo inesisekelo sabathengi esizinzile emakethe, ikakhulukazi ethandwa abathengi abakhetha ukukhetha okunoshukela omncane, okunamafutha aphansi, kanye nenempilo.

2. Ukucushwa Komugqa Wokukhiqiza: Ukuhlaziywa Kwezisetshenziswa Eziyinhloko

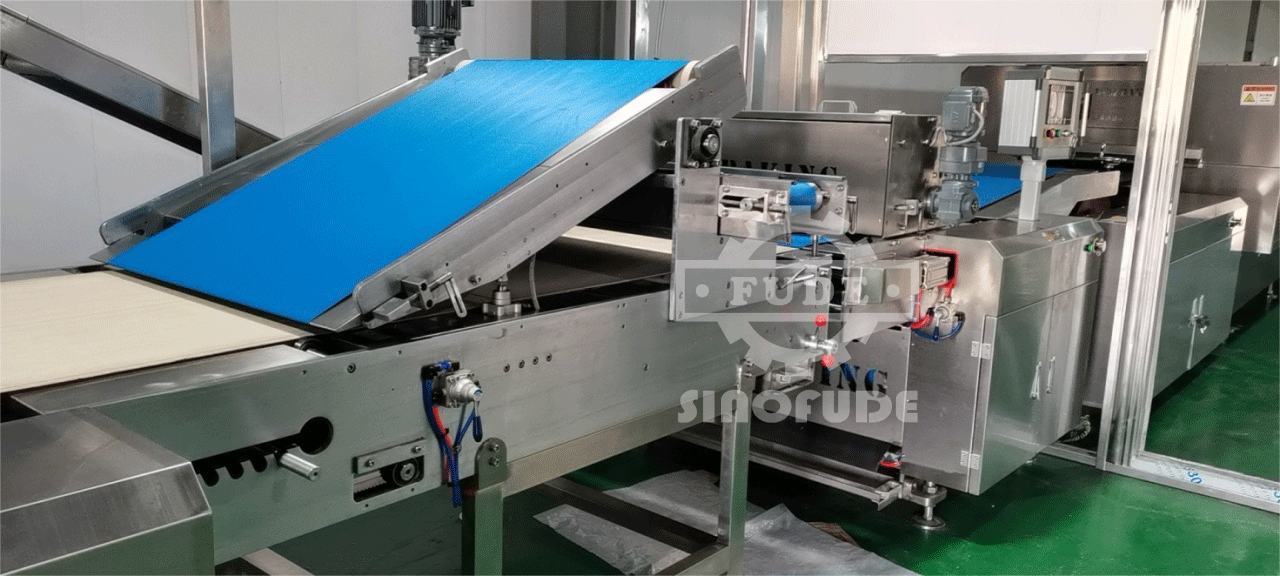

Ulayini ophelele wokukhiqiza amabhisikidi eHard wuhlelo oludidiyelwe oluhlanganisa izingcezu zemishini eminingi enemisebenzi ehlukile, okuhlanganisa umshini wokuhlanganisa inhlama, umshini wokwenza amabhisikidi, ihhavini kagesi yohlobo lomhubhe oshisayo, isifutho sikawoyela, umshini wokujika, ulayini wokupholisa, umshini wokuhlunga amabhisikidi, umshini wokugcwalisa amabhisikidi, kanye nesiteshi sokupakisha.

2.1 Imisebenzi Yezisetshenziswa Eziwumgogodla

Uhlelo Lokuxuba Inhlama: Lolu hlelo lulawula izinga lokushisa lenhlama nokuqina kokuxuba ukuze kuthuthukiswe ukwakheka kwe-gluten, okuyisisekelo sokuthungwa okuyingqayizivele kwamabhisikidi Aqinile.

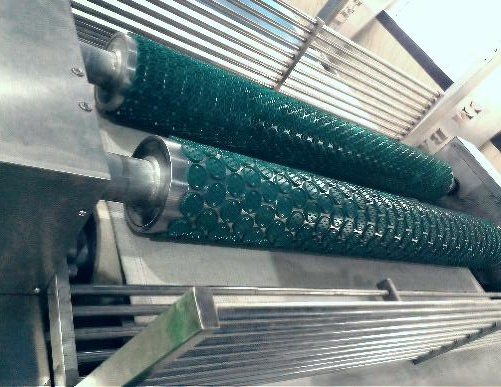

Uhlelo Lokwenza Inhlama: Ulayini wokukhiqiza amabhisikidi aqinile ngokuvamile usebenzisa inqubo yokwenziwa kwenhlama enezinyathelo ezintathu, kusetshenziswa amasethi amaningi amarola ukuze aqhubeke wakhe umugqa wenhlama efanayo. Amabhisikidi aqinile akhiwa ngokuyinhloko kusetshenziswa amasu okusika ama-roller noma ama-stamping, kanti ukugxiviza kulungele ngokukhethekile amabhisikidi Aqinile anomumo we-concave.

Isistimu Yokubhaka: I-oven kagesi yohlobo lomhubhe oshisayo iyingxenye ebalulekile yomugqa wokukhiqiza, ngokuvamile igcina izinga lokushisa lokubhaka elingu-200-300 ° C. Le ovini inikeza inkambu yokushisa efanayo futhi ezinzile, iqinisekisa ukubhaka ngesikhathi esisodwa inhlama yebhisikidi ngesikhathi sokuthutha, okuholela ekwakhiweni okuyingqayizivele kwezendlalelo kanye nokuthungwa okucwebezelayo.

Uhlelo Lokupholisa Nokupakisha: Amabhisikidi abhakiwe apholiswa ngokwemvelo ngomugqa wokupholisa owelula amashumi amamitha ubude ukuze avimbele ukwakheka komswakamo ngemva kokupakishwa, okungase kuthinte ukucwazimula kwawo. Umshini wokugoqa olandelayo kanye netafula lokupakisha kuqedela ukuhleleka kahle kanye nokupakishwa kokugcina kwamabhisikidi.

2.2 Imininingwane Yomugqa Wokukhiqiza

Ngokuya ngomthamo wokukhiqiza, ulayini wokukhiqiza amabhisikidi we-Fuda Hard unikeza amasayizi ahlukahlukene. Amamodeli avamile ahlanganisa: 480 (ububanzi bebhande le-mesh), i-600, ne-1000, nemiphumela esukela ku-250 kuya ku-1500 kg / h.

3. Inqubo Emisha: Ubuchwepheshe Bokukhiqiza Amabhisikidi Aqinile

Ngokuhlukahluka kwesidingo semakethe, olayini bokukhiqiza amabhisikidi aqinile benza ukuthuthukiswa okuqhubekayo kwezobuchwepheshe, okuholela ekuveleni kwezinqubo ezihlukahlukene ezikhethekile.

3.1 Ubuchwepheshe be-Multi-Layer Hard biscuit

Indlela entsha yokukhiqiza amabhisikidi anezingqimba eziningi iye yamukelwa kabanzi embonini. Lobu buchwepheshe buqala ngokudlulisela inhlama exotshiwe ibe ama-hopper okuphakelayo amabili noma ngaphezulu ahlukene, ngalinye elidlula okungenani amasethi amabili amarola ukuze kwakhe umugqa wenhlama. I-slurry ibe isisetshenziswa emgqeni wenhlama owodwa futhi ifakwe ngaphansi komunye, iwugqinsile. Ngemva kokudlula ama-roller amaningana, ifakwa emshinini wokugcoba ama-laminations amaningi. Ekugcineni, idlula okungenani isethi eyodwa yamarola ukuze yakhe inhlama ibe ugqinsi olufanele futhi iyabhakwa.

Le nqubo inika amandla ukukhiqizwa kwezingqimba eziningi zamabhisikidi Aqinile emigqeni yamabhisikidi ezenzakalelayo ekhona yohlobo lomhubhe, enikeza ukusebenza kahle okuphezulu kokukhiqiza. Amabhisikidi Aqinile aphumayo afaka izingxenye eziphambanayo eziningi, okuholela ekwenziweni okushelelayo nokuncibilika okuthuthuke kakhulu uma kuqhathaniswa namabhisikidi Aqinile avamile.

3.2 Ubuchwepheshe Bamabhisikidi Ongqimba Olubili Obucwebezelayo nobuqinile

Okunye okuqanjwe kabusha ubuchwepheshe bokukhiqiza amabhisikidi ongqimba oluphindwe kabili. Lobu buchwepheshe bubeka umshini wamabhisikidi ohlanzekile ezingeni eliphezulu kanye nomshini we-Hard bhisikidi ezingeni eliphansi, okuvumela ibhande lokudlulisa uqweqwe lomshini wamabhisikidi ocwebile ukuthi litshekele phansi, ngaphezu kwebhande lokudlulisa uqweqwe lomshini we-Hard bhisikidi. Lokhu kulungiselelwa kuvumela ulayini wokukhiqiza ukuthi ungakhiqizi kuphela amabhisikidi acwebile noma ahlafunwayo ewodwa, kodwa futhi nenhlanganisela yamabhisikidi anengqimba ephindwe kabili ecwebezelayo, enothisa iminikelo yomkhiqizo.

3.3 I-Fermented Chewy Biscuit Technology

Isistimu yokuvubela eqhubekayo yenzelwe amabhisikidi ahlafunwayo avutshiwe. Lolu hlelo luqukethe inkundla kanye nebhande lokuthutha. Ithangi ligxunyekwe endaweni yesikhulumi, kune-hopper yokusabalalisa etholakala kwesokudla sethangi kanye nephampu yokulinganisa ngezansi. Ibhande eliyinhloko le-conveyor litholakala ngaphakathi komhubhe wokuvutshelwa futhi lixhuma endaweni yepompo yemitha. Ngaphakathi komhubhe wokuvutshelwa, i-laminating roller itholakala ngenhla kwekhanda lebhande le-conveyor, i-roller ephendukayo itholakala ngenhla komsila, futhi i-chute yokukhipha itholakala ngezansi.

Lo mklamo uvumela ukuvutshelwa okuqhubekayo kanye nokungenelela okuqondile kanye nokulawula phakathi nenqubo yokuvutshelwa, ukuthuthukisa umthamo wokukhiqiza ukudla okuvutshiwe kanye nekhwalithi ngenkathi kunciphisa izindleko zabasebenzi.

4. Amathrendi Entuthuko kanye Neziqondiso Zokusungula

Uma sibheka phambili, imboni yokukhiqiza amabhisikidi ehlafunwayo ikhombisa ukuthambekela okucacile kokusebenza kahle okuphezulu, ubuhlakani obukhulu, kanye nokuvumelana nezimo okukhulu.

4.1 Izinsizakusebenza Eziningi

Imigqa yesimanje yokukhiqiza amabhisikidi iqhubekela phambili ekusebenzeni okuningi. Thatha ulayini wokukhiqiza wamabhisikidi aqinile ozenzakalelayo, osebenza ngezindlela eziningi njengesibonelo. Le mishini ingakhiqiza womabili amabhisikidi Aqinile kanye neminye imikhiqizo ehlukahlukene, okuhlanganisa amabhisikidi acwebile, amabhisikidi esangweji, ama-soda crackers, amabhisikidi aqinile, amabhisikidi emifino, namabhisikidi ezinhlamvu eziningi. Lo mklamo onemisebenzi eminingi uthuthukisa kakhulu ukusetshenziswa kwemishini kanye nokuvumelana nezimo kokukhiqiza, usize izinkampani ziphendule ngokushesha ezinguqukweni zemakethe.

4.2 Ubuhlakani kanye ne-Automation

Wonke ulayini usebenzisa isilawuli semojula ye-PLC kanye ne-motor drive efakwe ngemuva, okuholela ekwakhiweni okuhlangene kanye nezinga eliphakeme lokuzenzakalelayo. Kusukela ekuphakeleni, ukucindezela inhlama yezigaba ezintathu, ukubunjwa, ukuhlola ushukela, ukudlulisa, ukugaywa kabusha kwemfucuza, ukubhaka, ukufutha uwoyela, nokupholisa, yonke imisebenzi yenziwa ngokuzenzakalelayo ngokuhlanganisa i-mechatronic. Lo mugqa wokukhiqiza ozenzakalelayo kakhulu unciphisa kakhulu ukungenelela okwenziwa ngesandla, ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nokuvumelana komkhiqizo.

4.3 Ukwehlukahlukana Kwezamandla kanye Nokonga Amandla

Imigqa yokukhiqiza yamabhisikidi aqinile yesimanje inikeza amandla ahlukahlukene, okuhlanganisa ukushisisa kukagesi okukude nokubhaka ngegesi. Amahhavini okubhaka ngegesi athandwa kakhulu yizinkampani ngenxa yokuthi akhiqiza amabhisikidi anombala ophakeme kanye ne-flavour uma kuqhathaniswa nezinye izindlela zokushisisa, anikeza izinzuzo ezinhle zezomnotho zesikhathi eside, futhi anikeza izici zokonga amandla.

5. Isifinyezo

Njengengxenye ebalulekile yemishini yemboni yokudla, ulayini wokukhiqiza amabhisikidi oqinile usekela ukukhiqizwa okukhulu, okusezingeni eliphezulu kwamabhisikidi aqinile ngokusungula izinto ezintsha zobuchwepheshe kanye nokwenza kahle inqubo. Kusukela ezingxenyeni zomugqa wokukhiqiza oyisisekelo kuya ezenzweni ezintsha zezinqubo eziyingqayizivele, futhi kusukela esimweni samanje semboni kuya ezinkambisweni zesikhathi esizayo, umugqa wokukhiqiza amabhisikidi oqinile ubonisa ukuhlanganiswa okujulile kwemboni yokudla yendabuko kanye nobuchwepheshe besimanje.

Ngokukhula kwesidingo sabathengi sokudla okunempilo nokuhlukahlukene kanye nokuthuthuka okuqhubekayo kobuchwepheshe bokukhiqiza obukhaliphile, imigqa yokukhiqiza amabhisikidi eqinile izothuthukela ekusebenzeni kahle okukhulu, ubuhlakani, kanye nokuvumelana nezimo, ihlinzeke imakethe ngemikhiqizo yamabhisikidi eqinile esezingeni eliphezulu futhi ihlangabezane nezidingo zabathengi ezikhulayo ezihlukahlukene.

Xhumana Nathi

Vele ushiye i-imeyili yakho noma inombolo yocingo efomini lokuxhumana ukuze sikwazi ukukunikeza ngamasevisi engeziwe!ifomu lokuxhumana ukuze sikwazi ukukunikeza ngamasevisi amaningi!

Copyright © 2026 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com Wonke Amalungelo Agodliwe.