In the biscuit industry, Hard biscuit production lines, as core technical equipment, support the large-scale production of classic Hard biscuit products such as milk biscuits, vanilla biscuits, and egg biscuits with their unique technical approach and process characteristics. This article will systematically analyze the technical characteristics, current status, and development trends of Hard biscuit production lines from an industry perspective.

1. Overview of Hard biscuits: Characteristics and Classification

Hard biscuits differ fundamentally from crispy biscuits in terms of formulation and texture. According to industry standards, Hard biscuits have a lower sugar-to-oil ratio, typically keeping the sugar content below 30% and the oil content below 20%. This stands in stark contrast to the higher sugar-to-oil ratio in crispy biscuits.

The key characteristics of Hard biscuits include: a predominantly concave pattern with pinholes on the surface, a smooth surface, a layered cross-section, and a crispy, chewy texture. These characteristics are directly derived from the specialized process flow of Hard biscuit production lines.

Common Hard biscuits include a wide variety of varieties, including milk biscuits, vanilla biscuits, egg biscuits, Marie biscuits, and Boston biscuits. These products have a stable consumer base in the market, particularly favored by consumers who prefer low-sugar, low-fat, and healthier options.

2. Production Line Configuration: Core Equipment Analysis

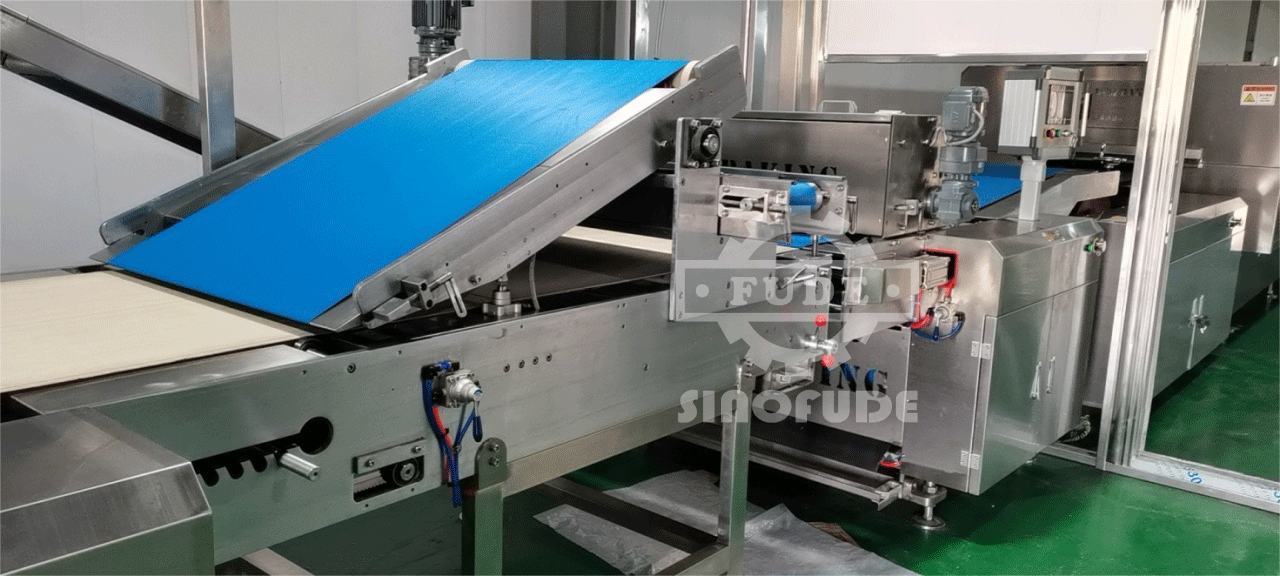

A complete Hard biscuit production line is a coordinated system comprised of multiple pieces of equipment with distinct functions, including a dough mixer, biscuit forming machine, tunnel-type hot air circulation electric oven, oil sprayer, turning machine, cooling line, biscuit sorting machine, biscuit filling machine, and packaging station.

2.1 Core Equipment Functions

Dough Mixing System: This system controls dough temperature and mixing intensity to promote gluten formation, which is the foundation for the unique texture of Hard biscuits.

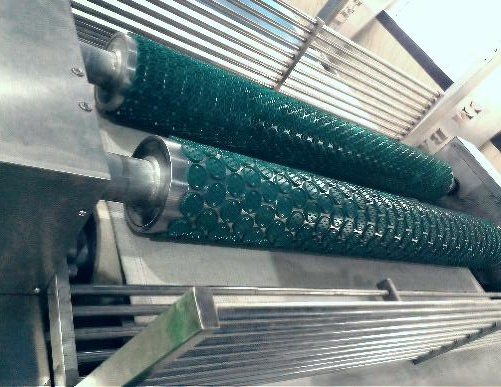

Dough Forming System: A Hard biscuit production line typically utilizes a three-step dough forming process, using multiple sets of rollers to continuously form a uniform dough strip. Hard biscuits are primarily formed using roller cutting or stamping techniques, with stamping being particularly suitable for Hard biscuits with concave shapes.

Baking System: The tunnel-type hot air circulation electric oven is a key component of the production line, typically maintaining a baking temperature of 200-300°C. This oven provides a uniform and stable heat field, ensuring simultaneous baking of the biscuit dough during transport, resulting in a unique layered structure and crispy texture.

Cooling and Packaging System: The baked biscuits are naturally cooled through a cooling line that stretches tens of meters in length to prevent moisture from forming after packaging, which could affect their crispness. The subsequent collating machine and packaging table complete the neat arrangement and final packaging of the biscuits.

2.2 Production Line Specifications

Depending on production capacity, the Fuda Hard biscuit production line offers a variety of sizes. Common models include: 480 (mesh belt width), 600, and 1000, with outputs ranging from 250 to 1500 kg/h.

3. Process Innovation: Specialized Hard biscuit Production Technology

With the diversification of market demand, Hard biscuit production lines are undergoing continuous technological innovation, resulting in the emergence of a variety of specialized processes.

3.1 Multi-Layer Hard biscuit Technology

An innovative method for producing multi-layer Hard biscuits has been widely adopted within the industry. This technology first conveys the kneaded dough into two or more separate feed hoppers, each of which passes through at least two sets of rollers to form a dough strip. Slurry is then applied to one dough strip and placed under another, overlapping it. After passing through several rollers, it is fed into a laminating machine for multiple laminations. Finally, it passes through at least one set of rollers to form the dough strip to an appropriate thickness and is baked.

This process enables the production of multiple layers of Hard biscuits on existing tunnel-type continuous automated biscuit lines, offering high production efficiency. The resulting Hard biscuits feature multiple cross-sections, resulting in a smoother texture and significantly improved meltability compared to conventional Hard biscuits.

3.2 Crisp and Tough Double-Layer Biscuit Technology

Another innovation is the crisp and tough double-layer biscuit production technology. This technology places the crisp biscuit machine on the upper level and the Hard biscuit machine on the lower level, allowing the crust conveyor belt of the crisp biscuit machine to tilt downward, above the crust conveyor belt of the Hard biscuit machine. This configuration enables the production line to produce not only crispy or chewy biscuits alone, but also a combination of crispy and chewy double-layer biscuits, enriching the product offerings.

3.3 Fermented Chewy Biscuit Technology

A continuous fermentation system has been developed for fermented chewy biscuits. This system consists of a platform and a conveyor belt. A tank is mounted on the platform, with a distribution hopper located to the right of the tank and a metering pump at the bottom. The main conveyor belt is located within the fermentation tunnel and connects to the metering pump outlet. Within the fermentation tunnel, a laminating roller is located above the conveyor belt's head end, a winding roller is located above the tail end, and a discharge chute is located below.

This design allows for continuous fermentation and direct intervention and control during the fermentation process, improving fermented food production capacity and quality while reducing labor costs.

4. Development Trends and Innovation Directions

Looking forward, the chewy biscuit production line industry is showing a clear trend towards higher efficiency, greater intelligence, and greater flexibility.

4.1 Multifunctional Equipment

Modern biscuit production lines are moving towards multifunctionality. Take the fully automatic, multifunctional, dual-purpose crisp and Hard biscuit production line as an example. This equipment can produce both Hard biscuits and a variety of other products, including crispy biscuits, sandwich biscuits, soda crackers, hard biscuits, vegetable biscuits, and multi-grain biscuits. This multifunctional design greatly improves equipment utilization and production flexibility, helping companies quickly respond to market changes.

4.2 Intelligence and Automation

The entire line utilizes PLC module control and a back-mounted motor drive, resulting in a compact structure and a high degree of automation. From feeding, three-stage dough pressing, forming, sugar screening, conveying, waste recycling, baking, oil spraying, and cooling, all operations are fully automated through mechatronic integration. This highly automated production line significantly reduces manual intervention, improving production efficiency and product consistency.

4.3 Energy Diversification and Energy Conservation

Modern Hard biscuit production lines offer a variety of energy options, including far-infrared electric heating and gas baking. Gas baking ovens are increasingly favored by companies because they produce biscuits with superior color and flavor compared to other heating methods, offer good long-term economic benefits, and offer energy-saving features.

5. Summary

As a crucial component of food industry equipment, the resilient biscuit production line supports the large-scale, high-quality production of resilient biscuits through continuous technological innovation and process optimization. From basic production line components to unique process innovations, and from the current state of the industry to future trends, the resilient biscuit production line demonstrates the deep integration of traditional food industry and modern technology.

With the growing consumer demand for healthy and diverse foods and the continuous advancement of intelligent manufacturing technology, resilient biscuit production lines will develop towards greater efficiency, intelligence, and flexibility, providing the market with more high-quality resilient biscuit products and meeting increasingly diverse consumer needs.

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.