Higher consistency, lower losses—purpose-built for modern beverage and topping markets.

Shanghai | SINOFUDE — A turnkey process spanning Cooking → Servo Depositing → Collection & Rinsing → Multihead Weighing & Filling → Terminal Sterilization.

Production line display

Four Core Modules

1) Cooking System

· Dedicated kettles for sodium alginate shell solution and juice-based core

· Steam-jacketed with scraper agitation (vacuum/atmospheric), inline temperature/°Brix; optional CIP and buffer/holding tanks

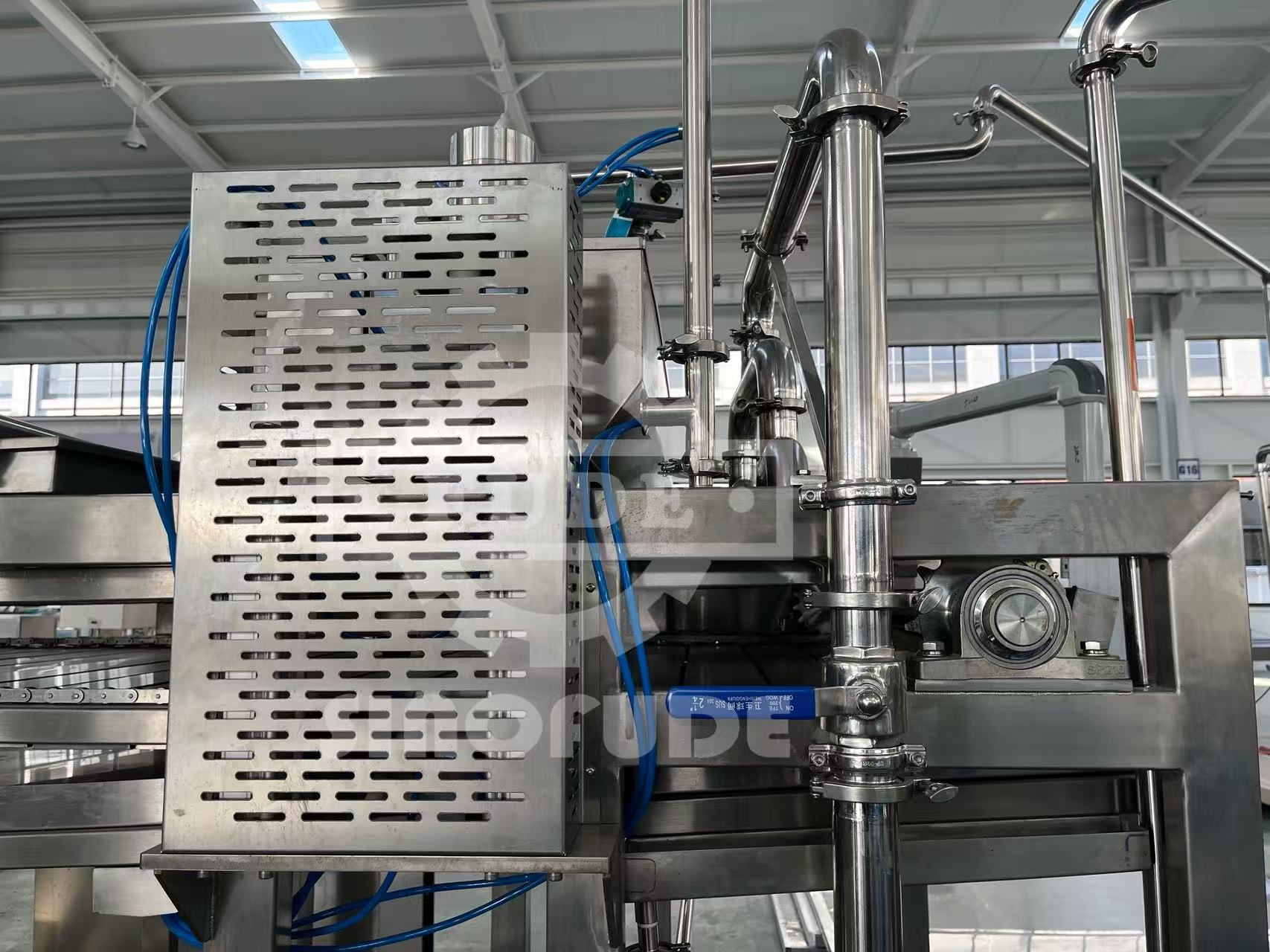

2) Forming System (Servo Depositing)

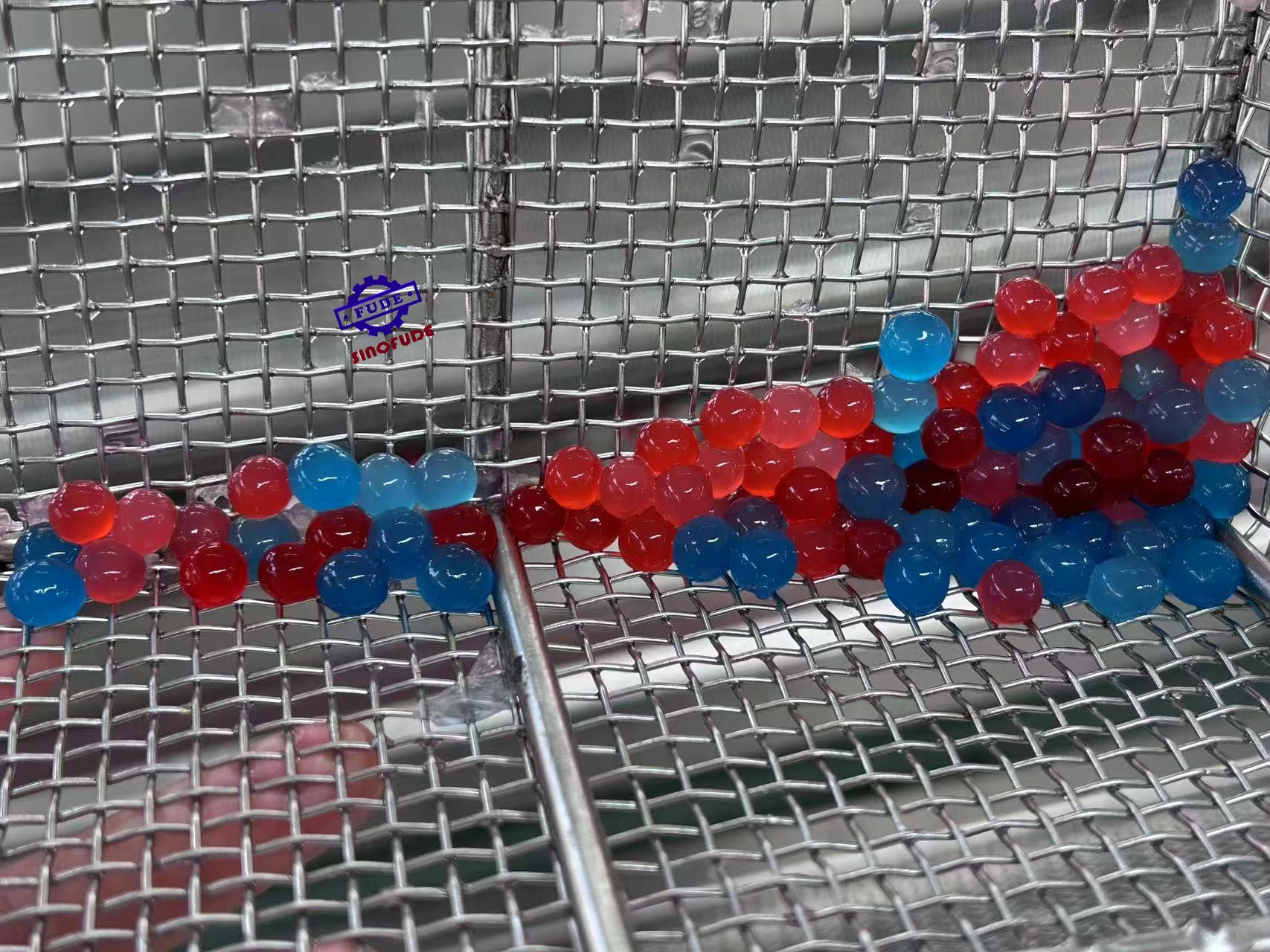

· Method: servo metering + multi-nozzle to dispense core into calcium bath (e.g., calcium lactate/chloride) for rapid alginate crosslinking

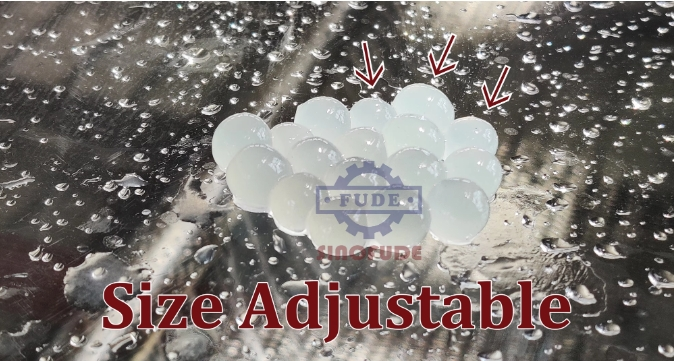

· Performance: fill-weight accuracy ≤ ±1.5%; diameter consistency ±0.3 mm (typical 8–10 mm); low tailing and rework

· Advantage: compensation for viscosity/temperature variation to stabilize shell thickness and geometry

PLC Control System

Depositing system

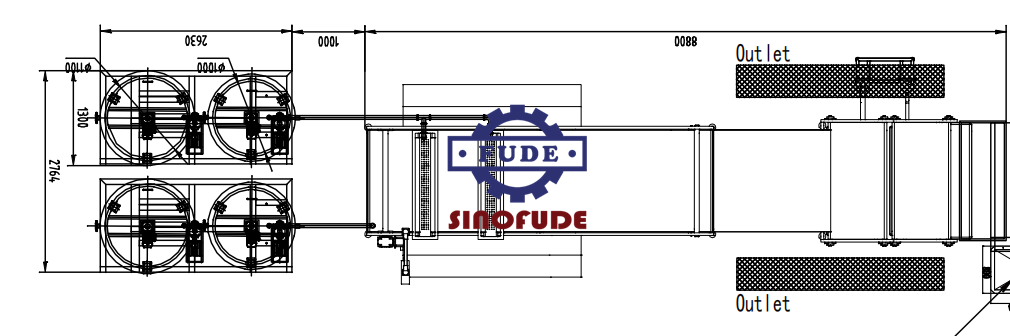

Process flow chart display

3) Collection & Packaging

· Flow: food-grade conveyors → rinse/separation → dewatering → multihead weigher for precise dosing

· Packs: pail/bag-in-box (e.g., 5–25 kg); optional syrup/preservation liquid to optimize texture and shelf life

4) Terminal Sterilization

· Retort (batch/loop) with pasteurization range (~85–95 °C) or high-temp cycles (up to 121 °C) as per recipe

Validated microbiological safety while protecting flavor and bite; aligned with HACCP/CE/GMP

Product Display

Key Specs & Materials

· Throughput: 150–600 kg/h (recipe/diameter dependent; customization available)

· Hygienic design: SUS316 product-contact, SU S304 elsewhere; sanitary quick-clamps and radiused transitions

· Controls: PLC + HMI (Siemens/Omron), one-touch recipe recall and batch traceability

· Options: inline Brix/viscosity, auto calcium make-up, chilled syrup loop, metal/weight check, remote service & dashboards

Use Cases

Milk tea chains, OEM co-packers, dairy/dessert toppings, and cross-category fruit-filled spheres.

Quote: “We put consistency and maintainability on equal footing. With advances in servo metering, bath circulation, and CIP, customers achieve round, clean-burst pearls while keeping downtime and loss under control.” — SINOFUDE Product Manager

About SINOFUDE

SINOFUDE delivers end-to-end solutions for confectionery, bakery, chocolate, and popping boba equipment—from lab-scale trials to full production lines.

Email: info@sinofude.com | Shanghai, China

Get In Touch With Us

Just leave your email or phone number on the contact form so we can provide you with more services!ontact form so we can provide you with more services!

Copyright © 2025 Shanghai Fude Machinery Manufacturing Co., Ltd. - www.fudemachinery.com All Rights Reserved.